Method for restraining supercharge gasoline engine super detonation through double-fuel injection

A gasoline engine and dual-fuel technology, applied in fuel injection devices, charging systems, mechanical equipment, etc., can solve problems such as super knocking, achieve the effects of suppressing early combustion, increasing the charge coefficient, and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

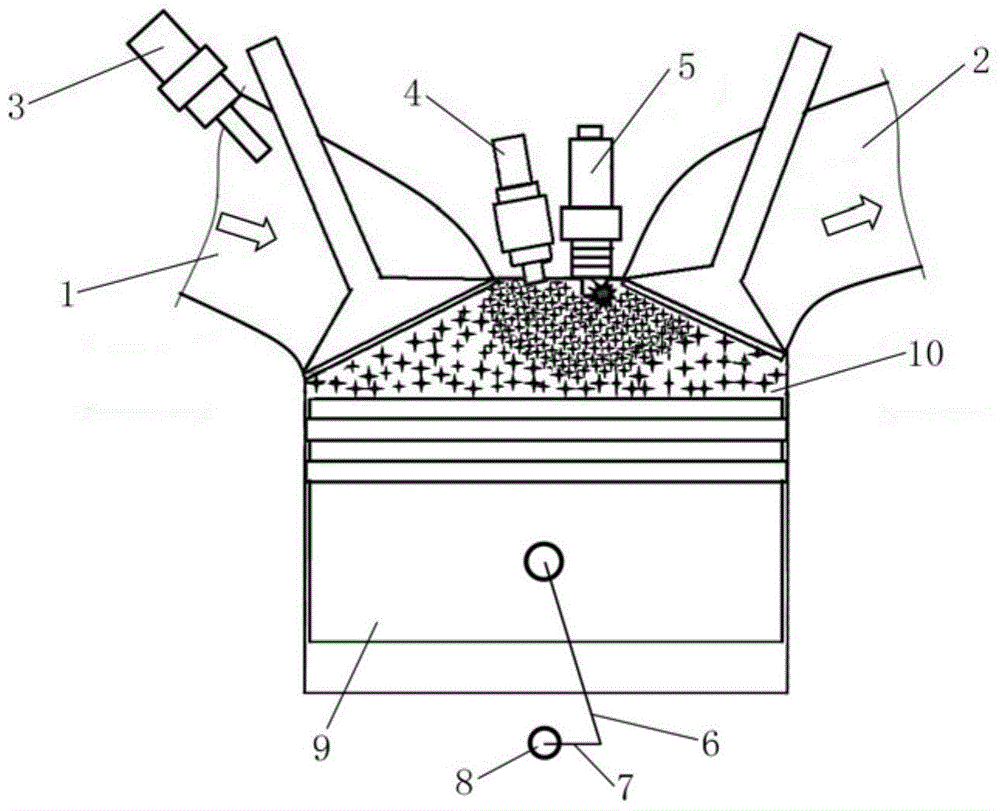

[0028] figure 1 It is a structural schematic diagram of a supercharged gasoline engine used to assist in explaining the method of suppressing the super-knock of a supercharged gasoline engine by using dual fuel injection. figure 1 Among them, the gasoline nozzle 3 is arranged in the intake passage 1, the alcohol fuel nozzle 4 is arranged in the combustion chamber 10, the air enters the combustion chamber 10 from the intake passage 1, the piston 9 moves downward, and the combustion chamber 10 is filled with air, gasoline and alcohol fuel mixture, then the piston 9 returns upwards to compress the mixture of air, gasoline and alcohol fuel, and when the piston 9 reaches the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com