Slagging agent and method for prolonging the service life of electric silicothermal vanadium iron electric furnace lining

An electrosilicothermic and ferrovanadium technology is applied in the field of slag-forming agents for prolonging the service life of ferrovanadium electric furnace linings by electrosilicic heating, and can solve the problems of reducing the service life of the furnace body, scouring and chemical erosion, and chemical erosion of the lining, etc. Improve chemical attack and physical attack, reduce chemical attack and physical attack, reduce the effect of physical attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: The method for prolonging the service life of the lining of the electric silithermal method ferrovanadium electric furnace adopts the following process and slagging agent.

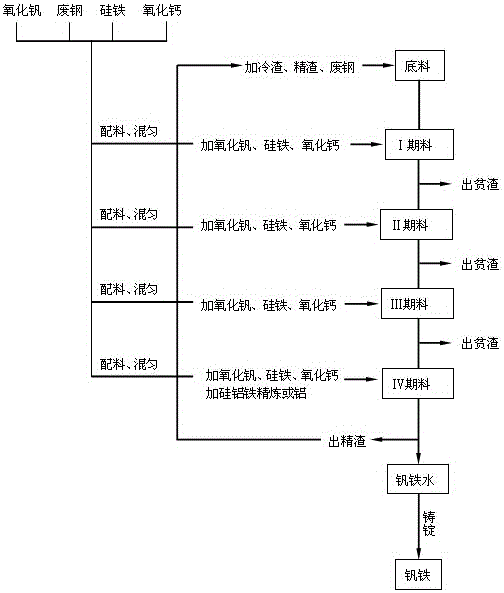

[0027] figure 1 As shown, taking a 3-ton electric arc furnace as an example, the total amount of calcium oxide added to the phase I material is 900kg (all heavy calcium oxide), and the total amount of calcium oxide added to the phase II material and phase III material is 1400kg , of which 700kg is magnesium-rich light calcium oxide. The total amount of calcium oxide in the fourth phase is 900kg, of which 450kg is magnesium-rich light calcium oxide. iron. The bulk density of the above-mentioned magnesium-rich light calcium oxide is 2.6g / cm 3 , MgO content is 6.8wt%. After long-term production, the product quality and unit output of this embodiment have no substantial change from those of conventional calcium oxide slagging agents, and the lining life is increased from 95 furnaces to ...

Embodiment 2

[0028] Embodiment 2: The method for prolonging the service life of the lining of the electrosilithermal ferrovanadium electric furnace adopts the following process and slagging agent.

[0029] Taking a 3-ton electric arc furnace as an example, the total amount of calcium oxide added to the phase I material is 900kg, of which 200kg is magnesium-rich light calcium oxide, and the total amount of calcium oxide added to the phase II and phase III materials is 1400kg, of which 800kg It is magnesium-rich light calcium oxide. The total amount of calcium oxide in the IV phase is 900kg, of which 400kg is magnesium-rich light calcium oxide. During the smelting process, the slag alkalinity is controlled at 2.0-2.2. After the smelting is completed, qualified 50-ferrosanadium is obtained. The bulk density of the above-mentioned magnesium-rich light calcium oxide is 2.4g / cm 3 , MgO content is 4wt%. After long-term production, the product quality and unit output of this embodiment have no su...

Embodiment 3

[0030] Embodiment 3: The method for prolonging the service life of the lining of the electrosilithermal ferrovanadium electric furnace adopts the following process and slagging agent.

[0031] Taking a 1.5-ton electric arc furnace as an example, the total amount of calcium oxide added to the phase I material is 450kg, all of which are heavy calcium oxide, and the total amount of calcium oxide added to the phase II and phase III materials is 700kg, of which 300kg is magnesium-rich Light calcium oxide, the total amount of calcium oxide in Phase IV is 450kg, of which 220kg is magnesium-rich light calcium oxide. During the smelting process, the basicity of the slag is controlled at 2.0-2.2. After the smelting is completed, qualified 50-ferrosanadium is obtained. The bulk density of the above-mentioned magnesium-rich light calcium oxide is 2.5g / cm 3 , MgO content is 10wt%. After long-term production, the product quality and unit output of this embodiment have no substantial change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com