Screw drill stator made using ECTFE and modified ECTFE applied to the stator

A screw drilling tool and stator technology, applied in the field of ECTFE, can solve the problems of affecting drilling efficiency and development progress, increasing drilling costs, and high maintenance requirements, and achieve the effect of reducing processing costs, reducing maintenance costs, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The components of this embodiment (in parts by weight) consist of: 100 parts of ECTFE, 3 parts of graphene fragment material, and 5 parts of carbon-skeleton porous nickel.

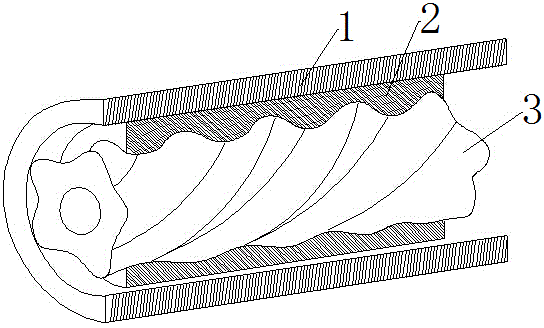

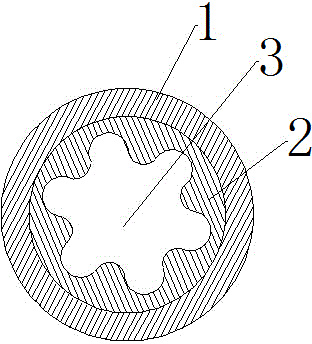

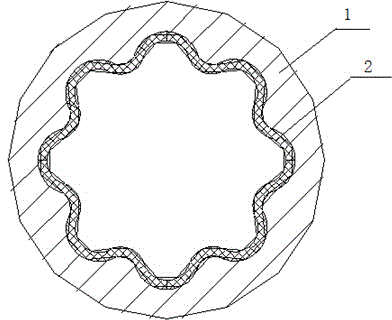

[0048] During production, ECTFE, carbon fiber nanotubes, and football ene C540 are uniformly mixed by a high-speed kneader, and then formed by extrusion, injection molding, or molding to obtain one of the application structures such as Figure 1-3 shown.

[0049] The product of this embodiment has been sampled and tested, and the results are as follows. The downhole stable use time is 300 hours, and the long-term use temperature is greater than 150 degrees.

Embodiment 2

[0051] The components of this embodiment (in parts by weight) consist of: 100 parts of ECTFE, 4 parts of graphene fragment material, and 10 parts of carbon-skeleton porous nickel.

[0052] During production, ECTFE, carbon fiber nanotubes, and football ene C540 are uniformly mixed by a high-speed kneader, and then formed by extrusion, injection molding, or molding to obtain one of the application structures such as Figure 1-3 shown.

[0053] The product of this embodiment has been sampled and tested, and the results are as follows. The downhole stable use time is 400 hours, and the long-term use temperature is greater than 170 degrees.

Embodiment 3

[0055] The components of this embodiment (in parts by weight) consist of: 100 parts of ECTFE, 5 parts of graphene fragment material, and 8 parts of carbon-skeleton porous nickel.

[0056] During production, ECTFE, carbon fiber nanotubes, and football ene C540 are uniformly mixed by a high-speed kneader, and then formed by extrusion, injection molding, or molding to obtain one of the application structures such as Figure 1-3 shown.

[0057] The product of this embodiment has been sampled and tested, and the results are as follows. The downhole stable use time is 640 hours, and the long-term use temperature is greater than 190 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long-term use temperature | aaaaa | aaaaa |

| Long-term use temperature | aaaaa | aaaaa |

| Long-term use temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com