Nano hydrophobic and oleophobic coating and preparation method of coating

A hydrophobic, oleophobic, and coating technology, applied in coatings and other directions, can solve the problems of uneven gel coating, small film thickness, and high equipment requirements, so as to improve drainage effect, reduce sliding angle, and increase contact corner effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

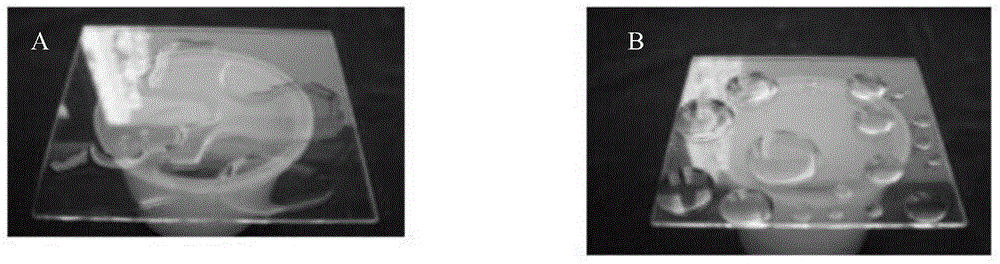

Image

Examples

Embodiment 1

[0022] Percentage by weight, ethanol 72%, isopropanol 6.9%, siloxane oligomer 20.1%, and the rest is the proportion of ethyl sulfate to obtain the solution after fully mixing. Wipe the glass surface to be treated with a non-woven cloth until the entire surface is completely wiped. After one minute, use the same non-woven cloth to wipe the surface in overlapping circles for one minute. Then use a clean non-woven cloth to wipe off the residual liquid on the glass surface, and then use microfiber cloth, cotton or paper towels to polish the surface of the material to complete the coating of the material surface film layer. After standing for a few minutes, it will be on the glass A nano-hydrophobic and oleophobic coating with a particle size of 30-50nm is formed on the surface. Perform a performance test and the results are as follows:

[0023] performance

[0024] Abrasion test: Use a one-pound stress abrasion head to treat the glass surface for 1600 cycles. The conta...

Embodiment 2

[0026] Percentage by weight, ethanol 73%, isopropanol 5.8%, siloxane oligomer 18.4%, and the rest is the proportion of ethyl sulfate to obtain the solution after fully mixing. Wipe the glass surface to be treated with a non-woven cloth until the entire surface is completely wiped. After one minute, use the same non-woven cloth to wipe the surface in overlapping circles for one minute. Then use a clean non-woven cloth to wipe off the residual liquid on the glass surface, and then use microfiber cloth, cotton or paper towels to polish the surface of the material to complete the coating of the material surface film layer. After standing for a few minutes, it will be on the glass A nano-hydrophobic and oleophobic coating with a particle size of 50-80nm is formed on the surface. Perform a performance test and the results are as follows:

[0027] performance

[0028] Abrasion test: Use a one-pound stress abrasion head to treat the glass surface for 1600 cycles. The conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com