Attachment oil high-position shelf stacking working platform

A workbench and high-position technology, applied in the direction of lifting devices, storage devices, transportation and packaging, etc., can solve the problems of potential safety hazards and high labor intensity, and achieve the effects of not being prone to operation errors, high degree of automation, and simplifying sending and receiving operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

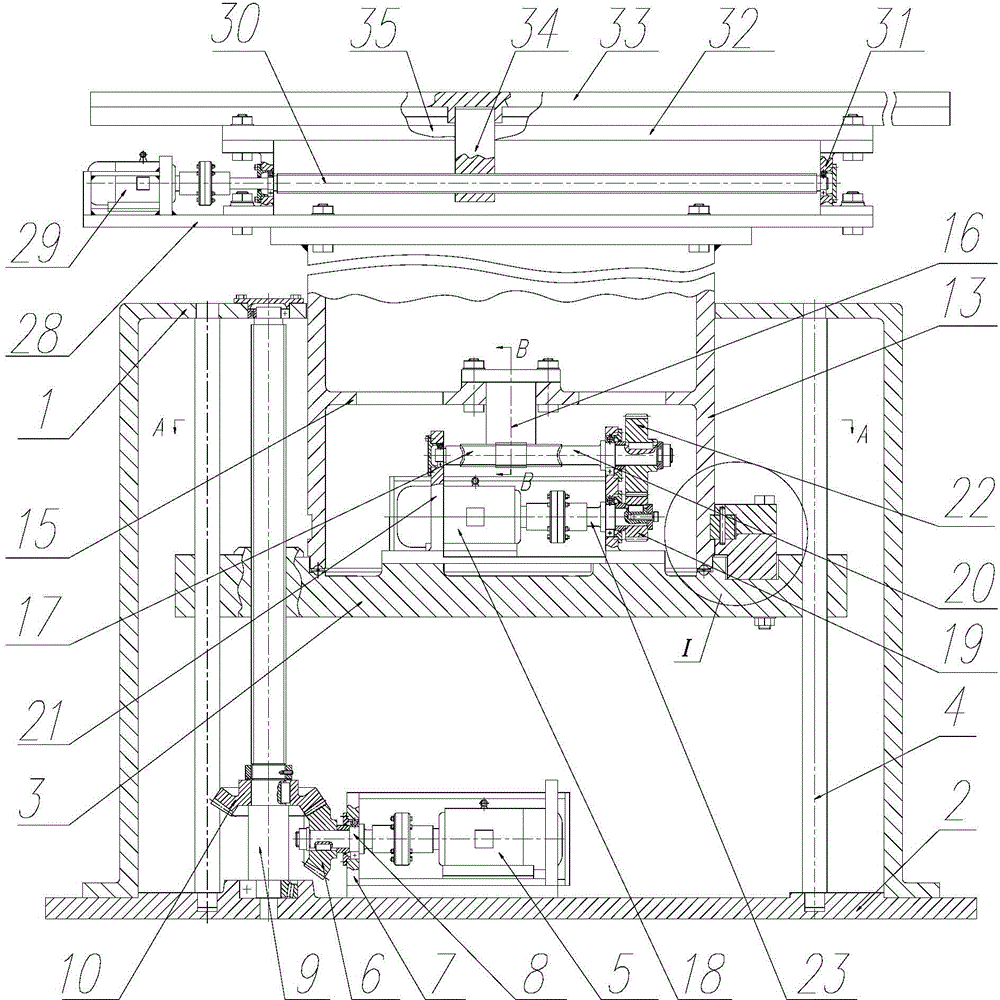

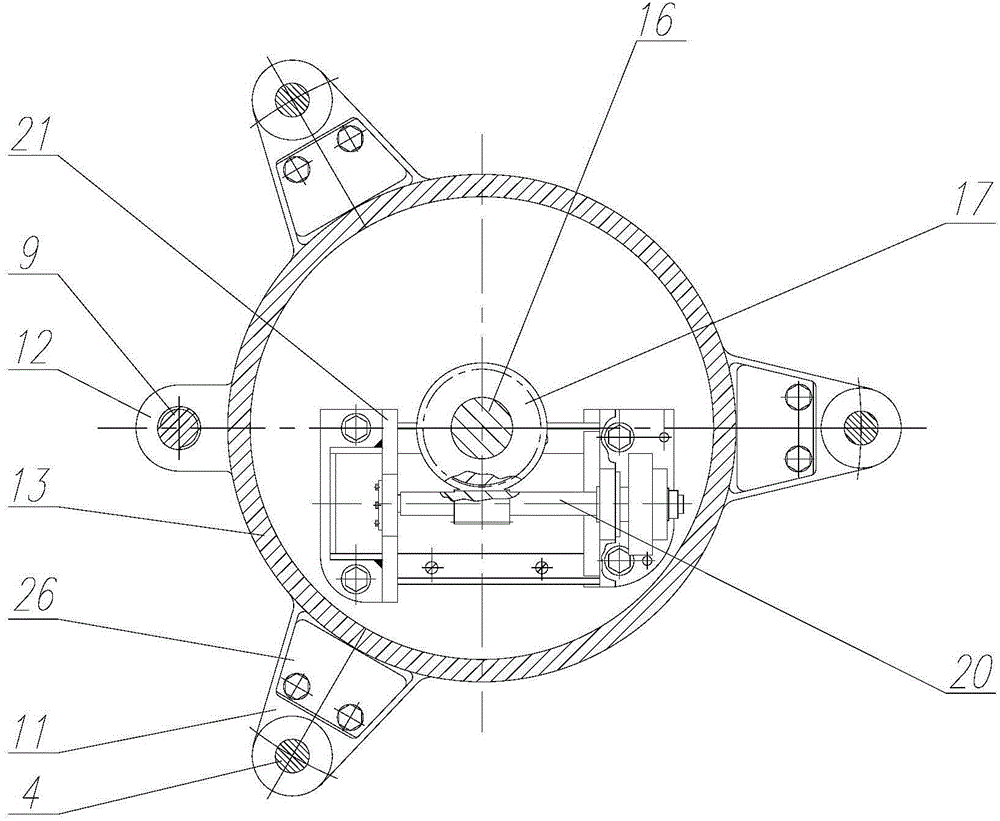

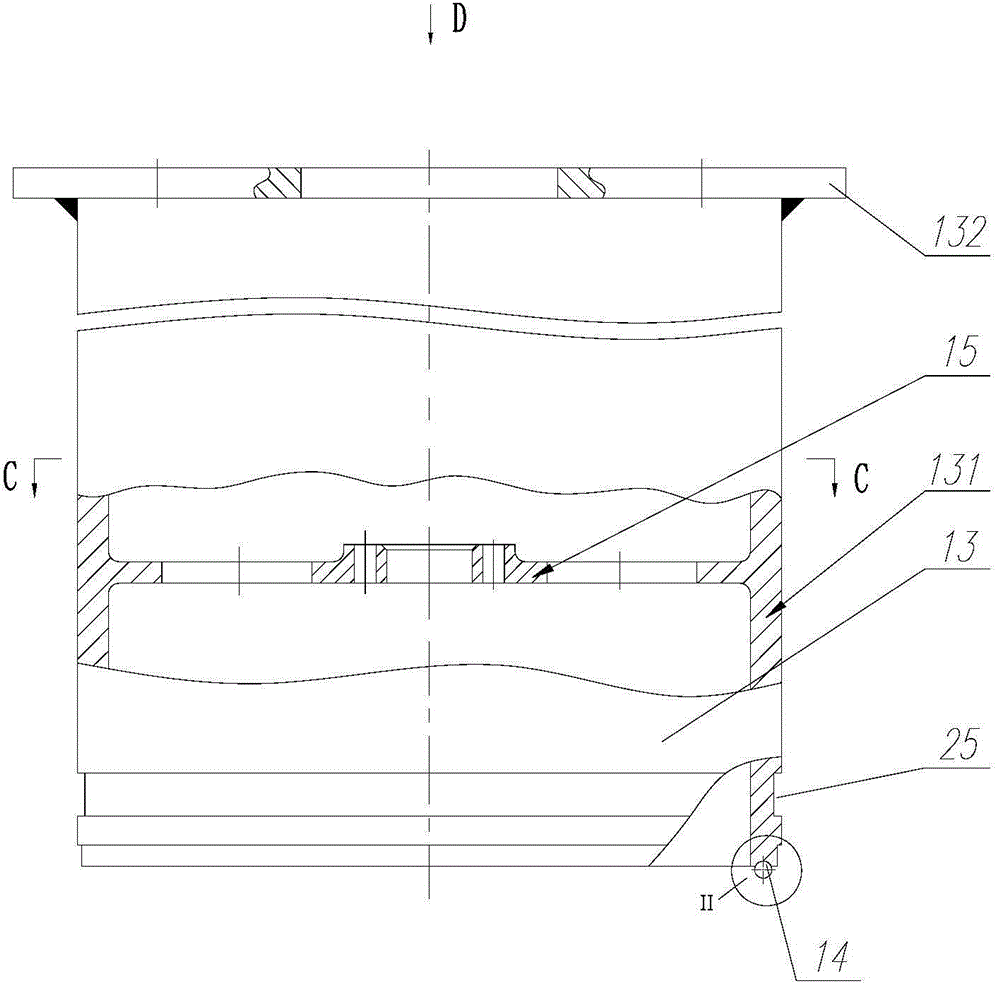

[0034] see Figure 1 to Figure 8 , is a preferred embodiment of the auxiliary oil high-level rack stacking operation platform, including a lifting mechanism, a transposition mechanism, and a translation mechanism.

[0035] see figure 1 , figure 2 Described elevating mechanism comprises frame, lifting table 3, and described frame has top plate 1, base 2 and is connected between top plate 1, base 2 three guide rods 4, and three guide rods 4 are arranged in equilateral triangle. Of course, the number of guide rods 4 can also be four, five..., and a plurality of guide rods 4 are arranged in a regular polygon. The edge of the frame top plate 1 extends downward to form a surrounding wall, and the lower end of the surrounding wall is fixedly connected with the base 2 . The base 2 is provided with a lifting motor 5, and the first bevel gear 6 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com