Bidirectional hydraulic jack

A two-way hydraulic, jack technology, applied in the direction of fluid pressure actuating devices, lifting devices, etc., can solve the problems of increasing mining difficulty and cost, environmental restrictions, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

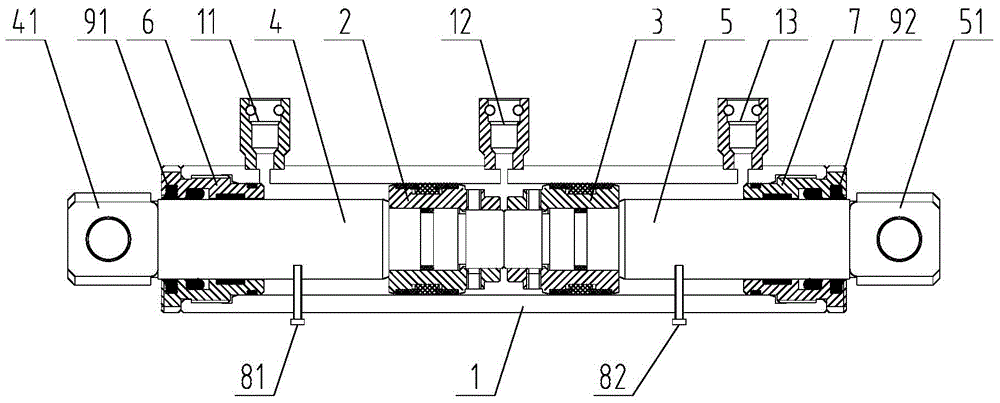

[0014] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a two-way hydraulic jack proposed by the present invention.

[0015] refer to figure 1 , a two-way hydraulic jack proposed by the present invention, comprising: a cylinder 1, a first piston 2, a second piston 3, a first piston rod 4, a second piston rod 5, a first guide sleeve 6, a second guide sleeve 7 ;

[0016] The inside of the cylinder 1 has a through cavity and openings at both ends. The side wall of the cylinder 1 is provided with a first through hole, a second through hole, a third through hole, a fourth through hole and a fifth through hole. The hole, the second through hole and the third through hole are sequentially arranged at intervals in the axial direction of the cylinder 1, the fourth through hole is located between the first through hole and the second through hole, and the fifth through hole is located between the second through hole and the second through hole. Between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com