Diffusion film feed mechanism

A technology of feeding mechanism and diffusion film, which is applied in thin material processing, winding strips, sending objects, etc., can solve the problems of low efficiency and high labor intensity, and achieve the effect of improving work efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

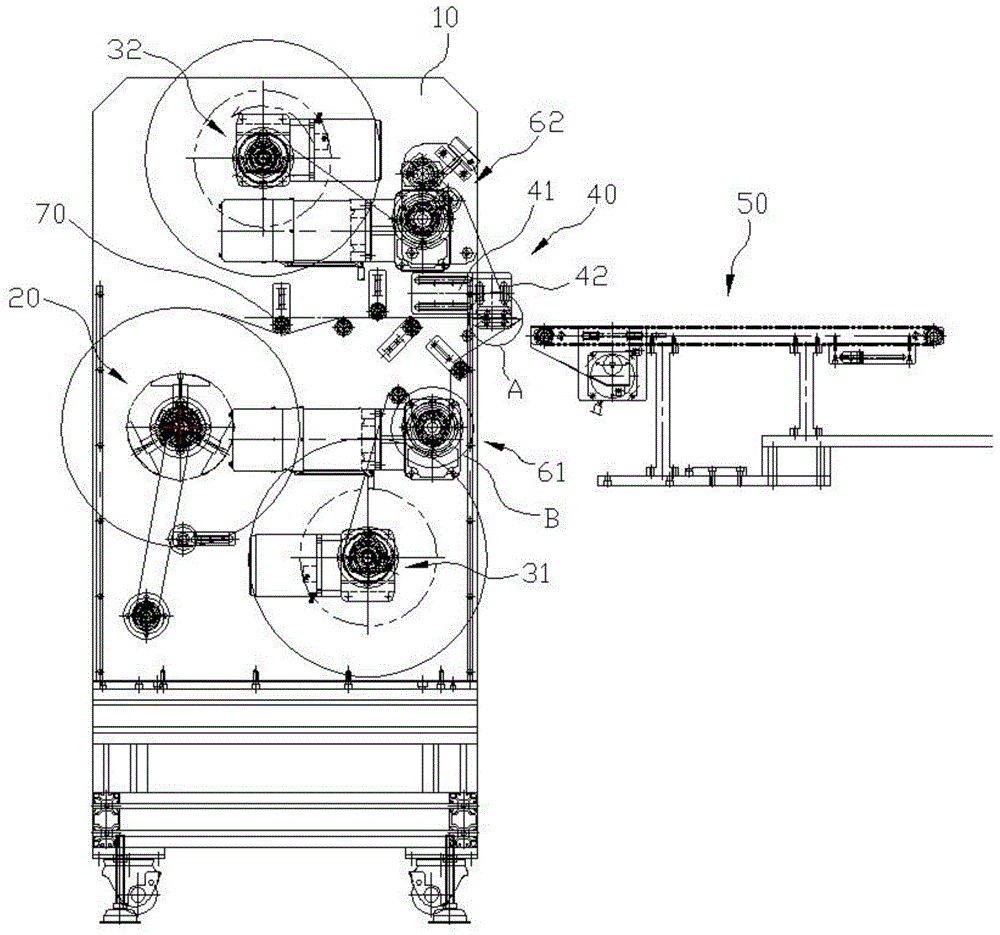

[0038] Such as figure 1 As shown, a kind of diffusion film feeding mechanism comprises frame 10, diffusion film winding device 20, base material winding device 31, protective film winding device 32, film stripping device 40, film conveying device 50, first A transfer device 61 , a second transfer device 62 , and several transfer rollers 70 .

[0039] Such as Figure 5 As shown, the diffusion film winding device 20 includes a rotating shaft 21 and a winding assembly 22, one end of the rotating shaft 21 is pivotally connected to the frame 10, and the winding assembly 22 is fixed on the other end of the rotating shaft , the diffusion film is wound on the winding assembly 22 . Wherein, the winding assembly 22 of the diffusion film winding device 20 includes three winding parts 221, and the winding parts 221 include a winding plate 2211 and a connecting block 2212, and the winding plate 2211 passes through the connecting block 2212 Installed on the rotating shaft 21 of the diffusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com