Novel rotating base

A rotating base, a new type of technology, applied in the direction of conveyors, bearing components, rigid supports of bearing components, etc., can solve the problems of poor sealing performance, easy failure, and inability to rotate, etc., to achieve good sealing performance, good centering effect, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

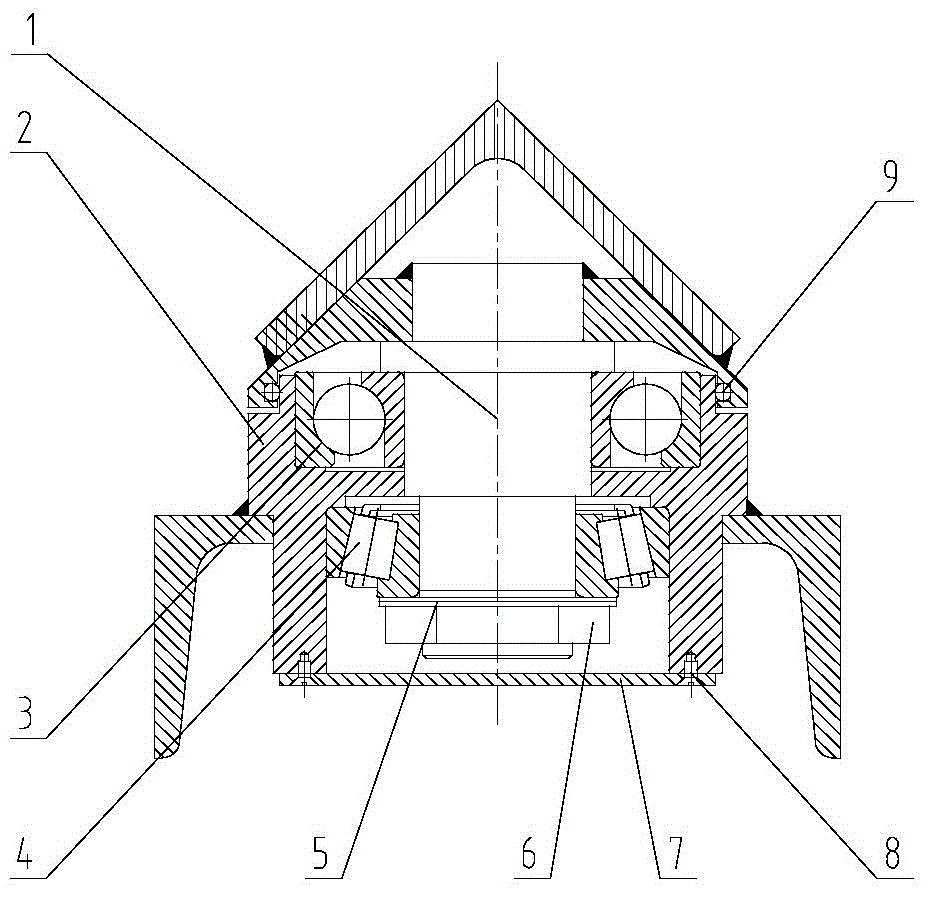

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

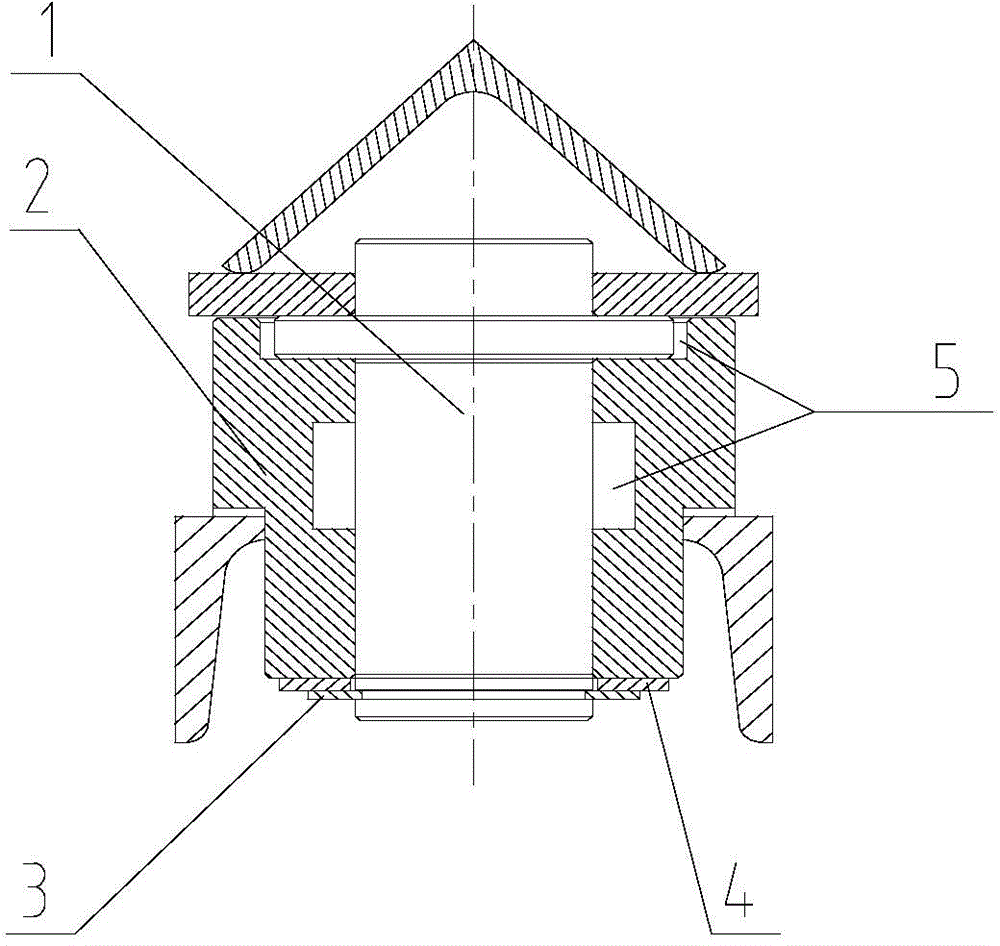

[0013] Such as figure 2 A new type of rotating base of the present invention is shown, which includes a shaft 1 welded to the upper beam of the self-aligning idler and a base 2 welded to the lower beam of the self-aligning idler. Angular contact bearings 3 and tapered roller bearings 4 are respectively installed at intervals between 2, the upper part of the base is nested in the lower part of the opening of the upper beam, and an O-ring is installed between the base and the nesting part of the upper beam 9. A washer 5 is sleeved on the shaft 1 at the lower end surface of the tapered roller bearing 4, and the washer 5 is pressed against the lower end surface of the tapered roller bearing 4 through a nut 6, and the bottom surface of the base is connected with a ( The fixing part can be bolt 8) base end cover 7.

[0014] The installation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com