Automatic sorting garbage can and sorting method

A technology for automatic sorting and trash cans, applied in the field of trash cans, can solve the problems of cumbersome processing procedures, waste of resources, and automatic sorting and processing of unsorted garbage that cannot be placed by intelligent pedestrians.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

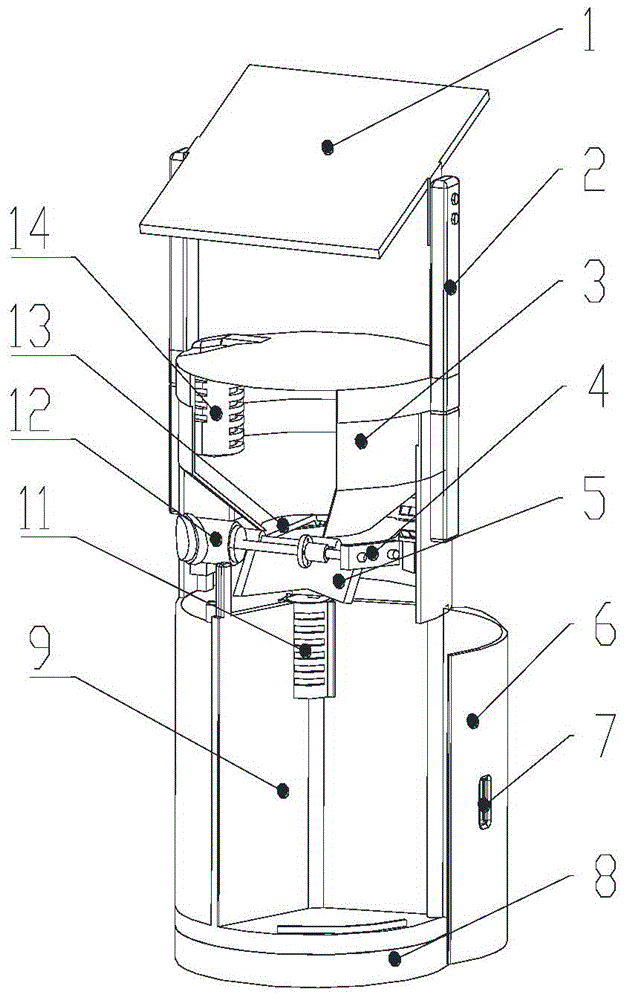

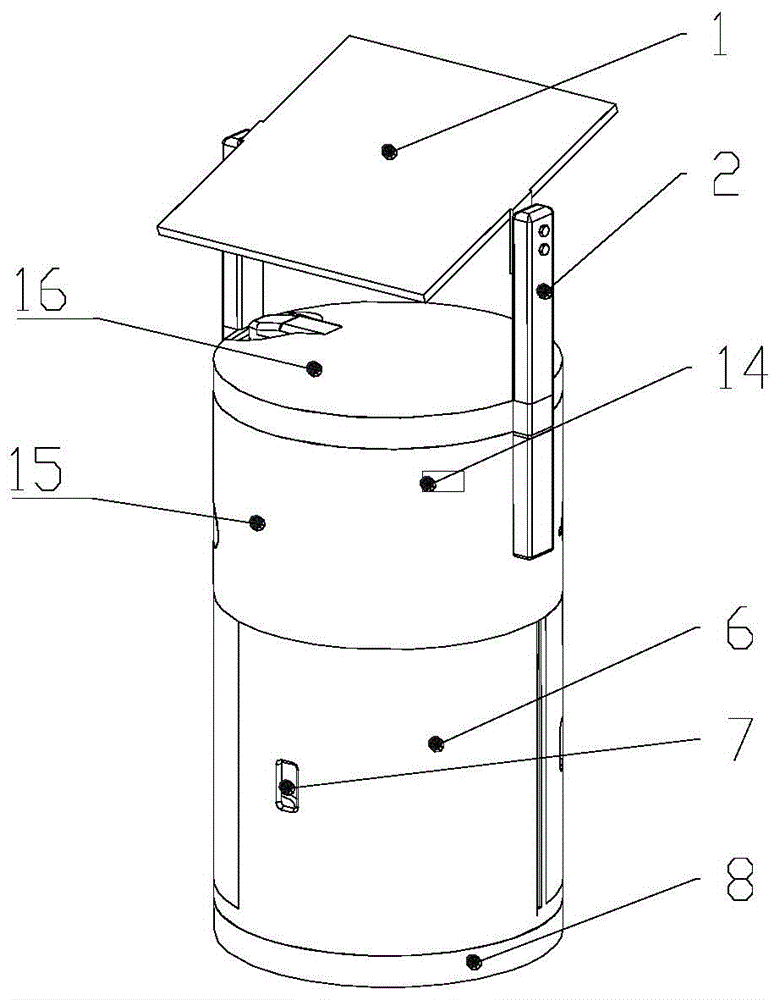

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] see figure 1 with figure 2 , an automatic sorting trash can, comprising an upper shell 15 and a lower shell 6 placed on a base 8, four independent inner tanks 9 are arranged in the lower shell 6, a collecting plate 3 is arranged in the upper shell 15, and the collecting plate 3 is provided with an audio sensor, the bottom of the collection plate 3 is provided with a guide plate 13 driven by the guide plate motor 12 that can be opened and closed, and the bottom of the collection plate 3 is provided with a guide plate that can be driven by the guide motor 11 and can be inclined to the four inner tanks 9 respectively 5. There is an upper cover 16 on the top of the upper shell 15, the upper cover 16 is connected with the upper cover motor 14, the audio sensor is connected with the control module, the control module is connected with the guide motor 11 and the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com