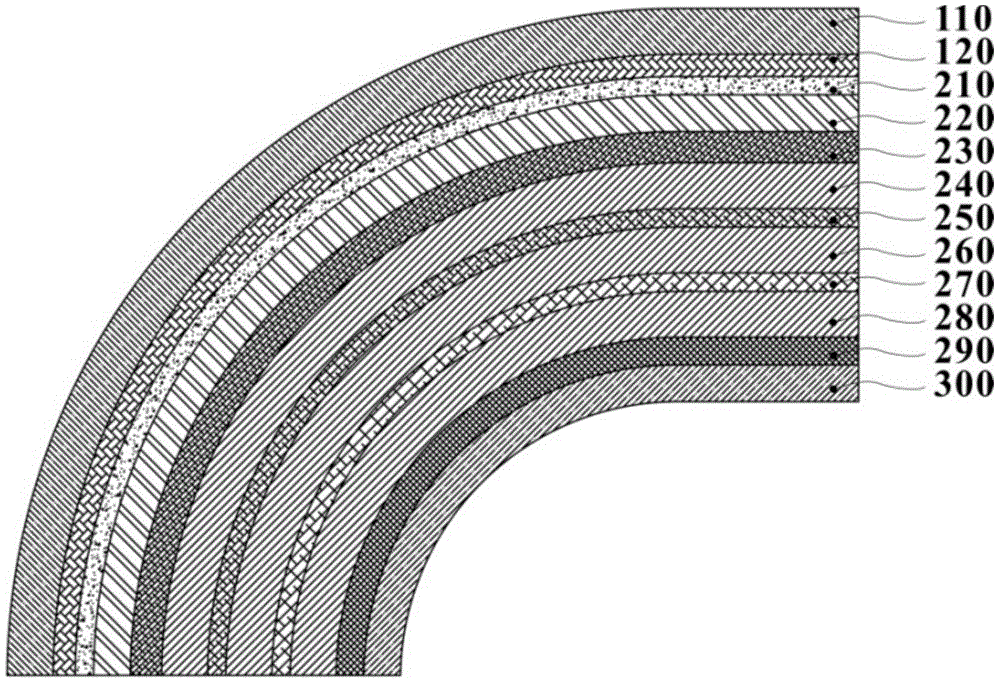

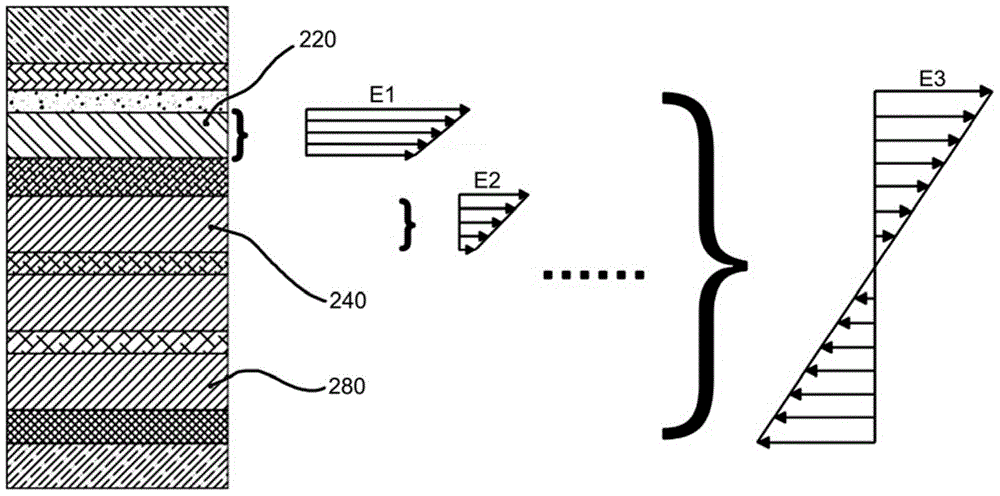

A multi-layer elastic composite film having functions of bending shape maintenance and impact resistance and a preparing method thereof

A composite film, impact-resistant technology, applied in chemical instruments and methods, laminated, layered products, etc., can solve problems such as inability to handle arc corners, cumbersome film sticking process, easy to wear, etc., to overcome bending elasticity and Differential stress distribution among different substrates, good arc surface fit and shape retention ability, good elastic vibration absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

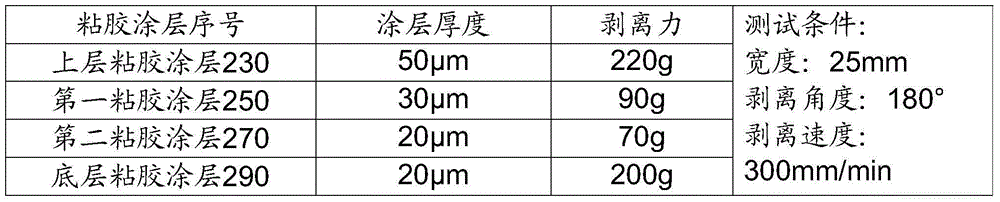

[0031] In order to further understand the features, technical means, and achieved specific objectives and functions of the present invention, and to analyze the advantages and spirit of the present invention, the present invention will be further described through the following examples.

[0032] The raw materials used in the embodiments of the present invention are as follows:

[0033] Silicone, acrylic glue, OCA optical glue, PU glue, pressure sensitive glue, purchased from Dongguan Tianyi Chemical Co., Ltd.;

[0034] Polyethylene terephthalate, low-density polyethylene, polypropylene film, polyvinyl chloride film, polycarbonate, purchased from Changxing (Guangzhou) Fine Coating Co., Ltd.;

[0035] Thermoplastic polyurethane, thermoplastic polyester elastomer, and styrene-based thermoplastic elastomer were purchased from Shanghai Rizhisheng New Technology Development Co., Ltd.;

[0036] UV coating material: epoxy acrylate coating, purchased from Dongguan Tianyi Chemical Co....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com