Fixing assembly and construction method for manufacturing concrete prefabricated part through fixing assemblies

A technology for concrete prefabricated parts and fixed components, which is applied in the direction of manufacturing tools, mold fixtures, mold auxiliary parts, etc., can solve the problems of easy falling off of tiles, high technical requirements of operators, waste of cement mortar, etc., to ensure the quality of paving. , the effect of reducing technical requirements and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

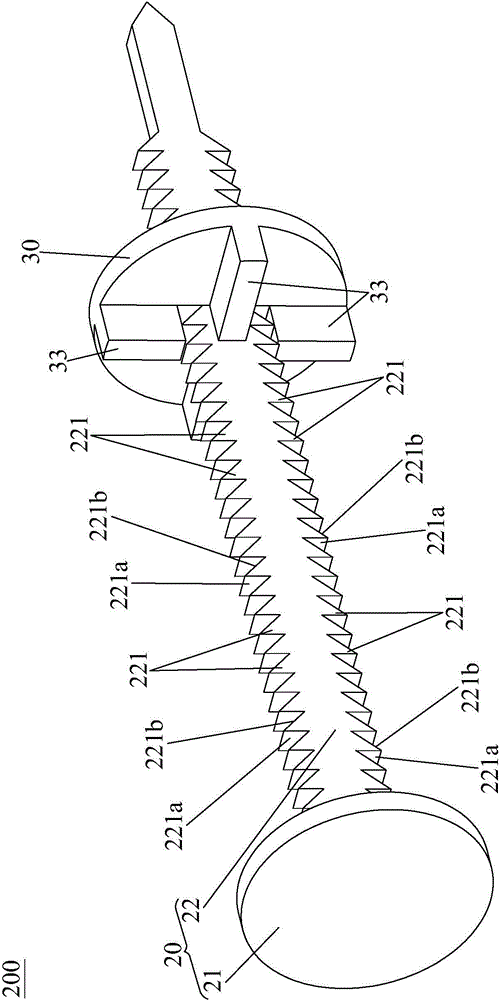

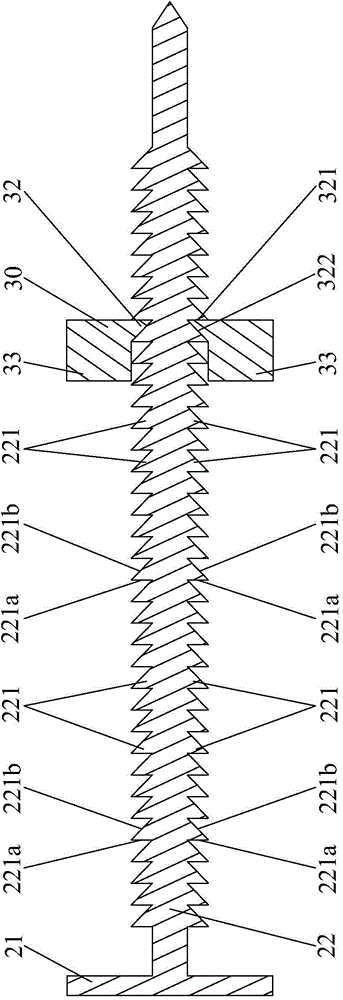

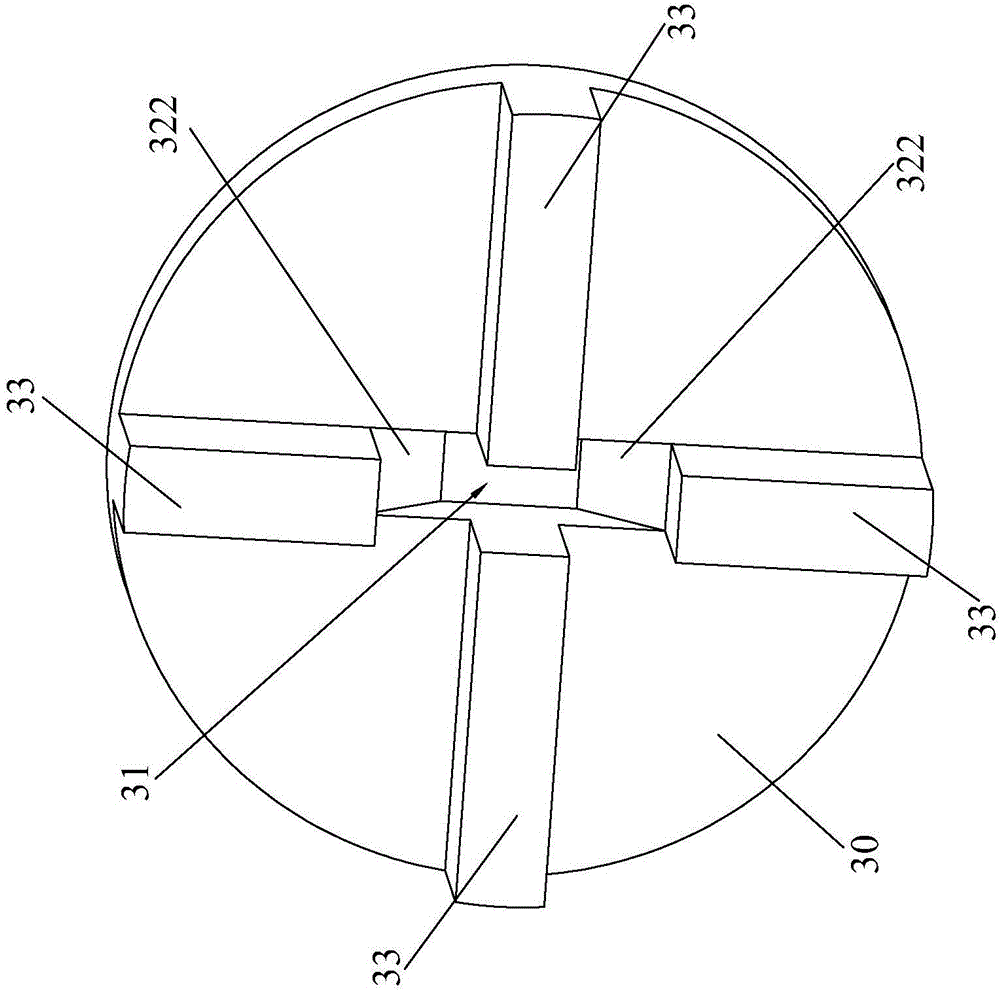

[0040] see Figure 1 to Figure 3 , shows the fixing assembly 200 of the first embodiment of the present invention. The fixing assembly 200 of this embodiment includes a locking band 20 and a locking member 30. The locking band 20 includes a contact head 21 and a connecting arm 22 connected to the contact head 21 The locking member 30 can be inserted into the connecting arm 22 , and the locking member 30 can be selectively locked and positioned on the connecting arm 22 along the length direction of the connecting arm 22 . Among them, such as Figure 4 As shown, the fixing assembly 200 of this embodiment is suitable for fixing sheet materials 40 such as tiles to a template 50 for making concrete prefabricated parts (not shown in the figure) (the template 50 is a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com