PBF vacuum filter flushing tank assembly

A vacuum filter and flushing water tank technology, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of affecting the use effect, unclean cleaning of the mesh belt, and friction affecting the service life of the mesh belt. Adjust the requirements, improve the flushing effect, and ensure the effect of the working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

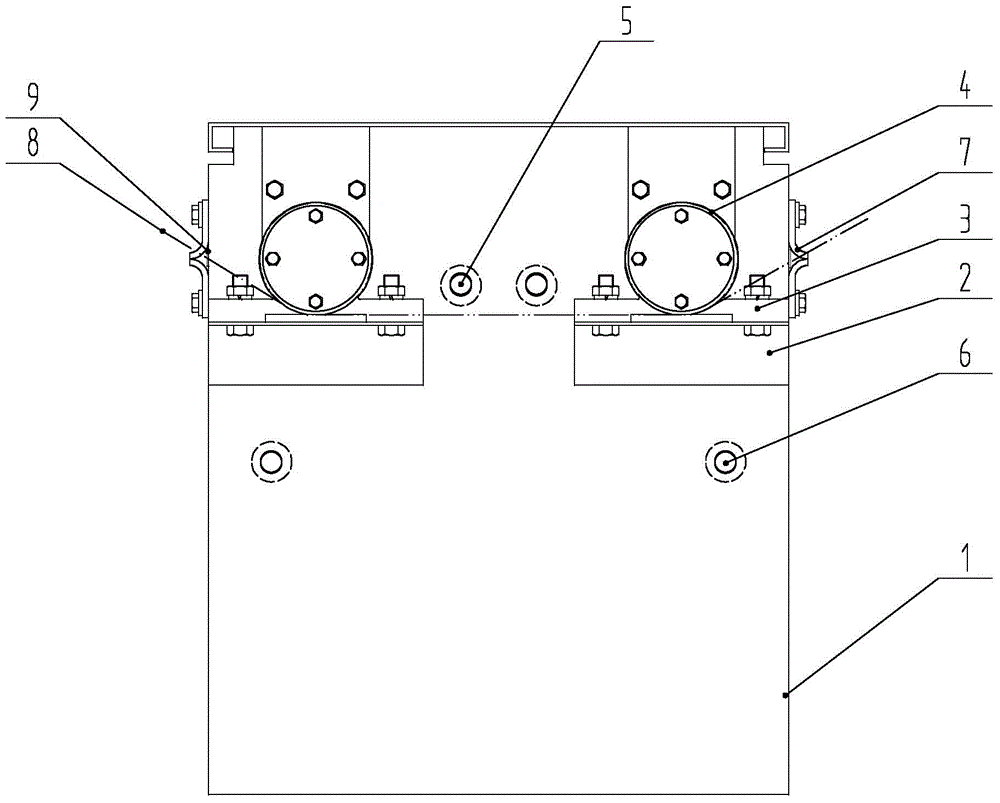

[0011] Such as figure 1 As shown, the present invention includes a box body 1, a bracket 2, a bearing seat 3, a guide roller shaft 4, an upper flushing pipe 5, a lower flushing pipe 6, and a sealing felt 7. It is characterized in that the front and rear sides of the box body 1 are respectively provided There are two brackets 2, and the brackets 2 are left-right symmetrical along the center line of the box body 1. A bolted bearing seat 3 is arranged above the bracket 2, and a guide roller shaft 4 is arranged between the bearing seats 3, and the wire roller shaft A mesh belt 8 is provided below, two upper flushing pipes 5 are arranged above the mesh belt 8, two lower flushing pipes 6 are arranged below the mesh belt 8, and inlets and outlets 9 are arranged on the left and right sides of the box body 1. , the center of the inlet and outlet 9 is at a horizontal position with the center of the guide roller shaft 4, and the inlet and outlet 9 is provided with a bolted sealing felt 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com