Swinging-type jet washing machine of dishwasher

A dishwasher, swing-type technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., can solve the problems of affecting the dishwasher, resource waste, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

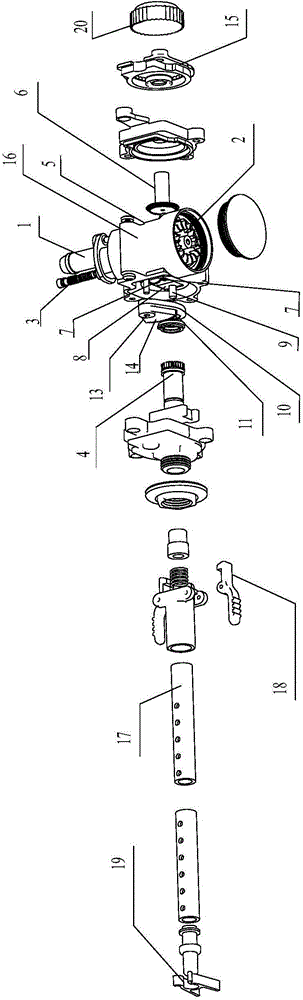

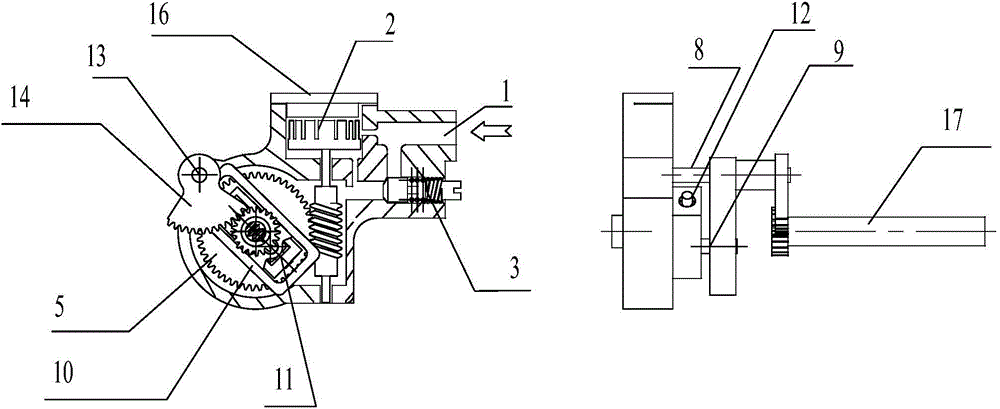

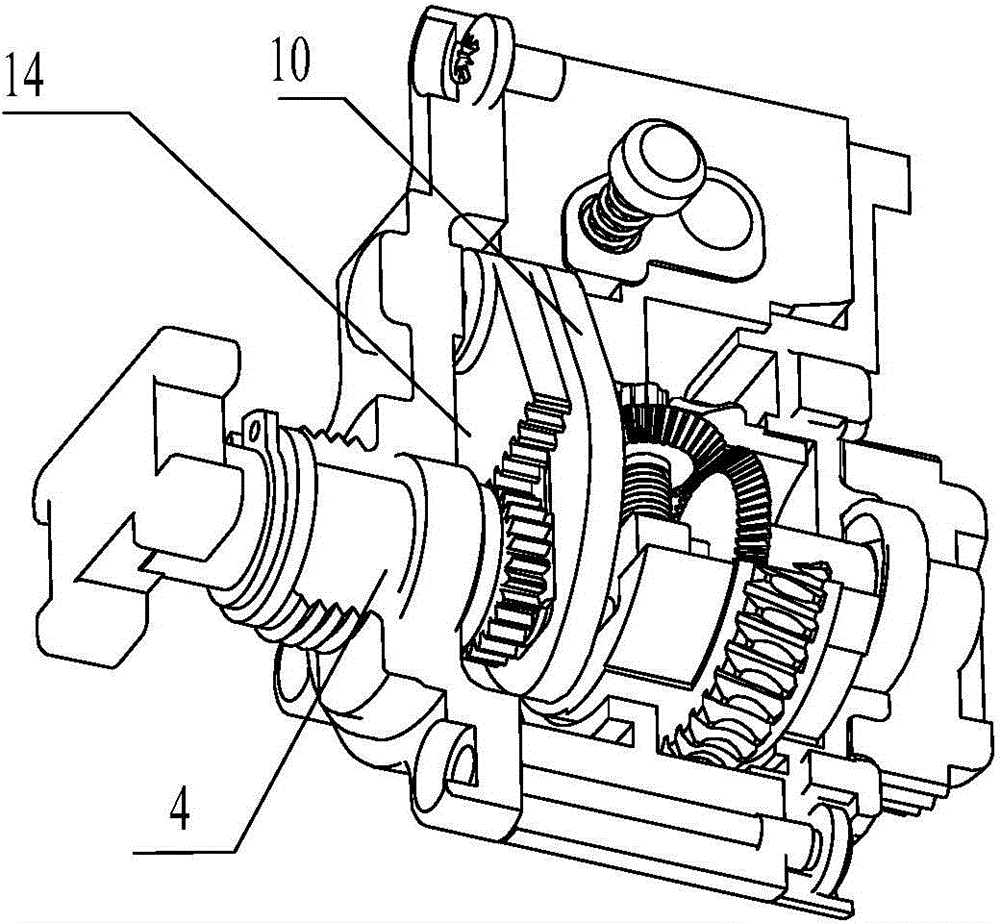

[0029] Such as Figure 1-Figure 9 As shown in the figure, a dishwasher swing-type washing jet includes a water inlet 1 and a housing 16 for connecting a water pump. The water inlet 1 is arranged on the housing 16, and the housing 16 is provided with a spray shaft 4. The spray shaft 4 The outer end is connected to the injection conduit 17, and the water inlet 1 is also provided with a throttle valve 3, and the water wheel 2 is arranged in the housing 16, and the water wheel 2 is connected with a worm gear reducer 5, and an eccentric slider 8 is arranged on the reducer 5 body. The eccentric slider 8 is connected to the swing rail 10 through the eccentric slider shaft 9, so that the water flow from the throttle valve 3 pushes the water wheel 2 to rotate, thereby realizing the left and right swinging motion of the swing rail 10; , the fan-shaped tooth 14 passes through, the swing rail shaft 13 is connected with the swing rail 10, and the swing rail 10 drives the injection shaft 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com