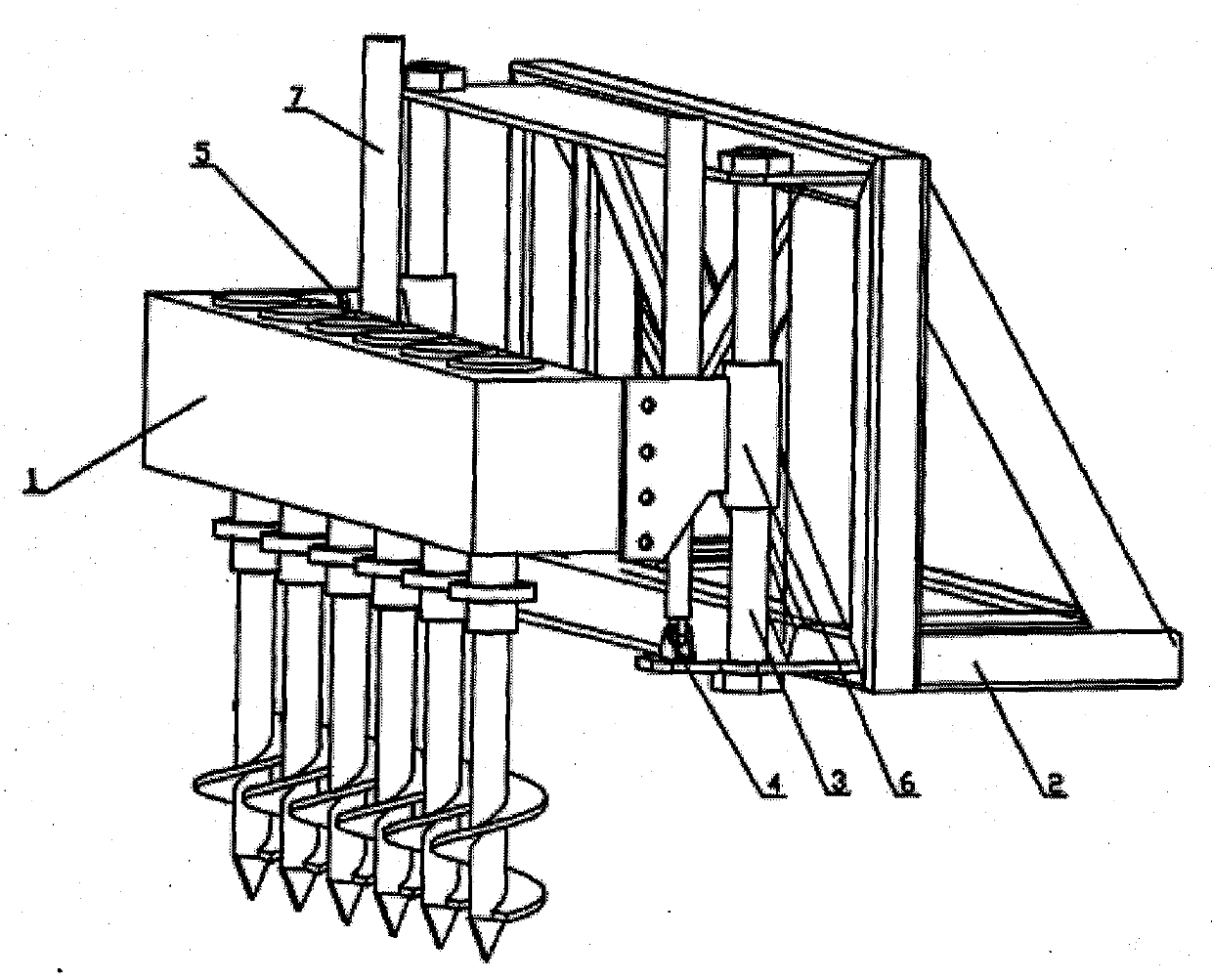

A cantilever vertical lifting system

A vertical lifting and cantilever technology, applied in the field of agricultural machinery, can solve the problems of unsuitable lifting of large-mass working parts, increased hydraulic cylinder load and power consumption, poor stability, etc., to achieve good structural stability and operational safety, realize disassembly, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

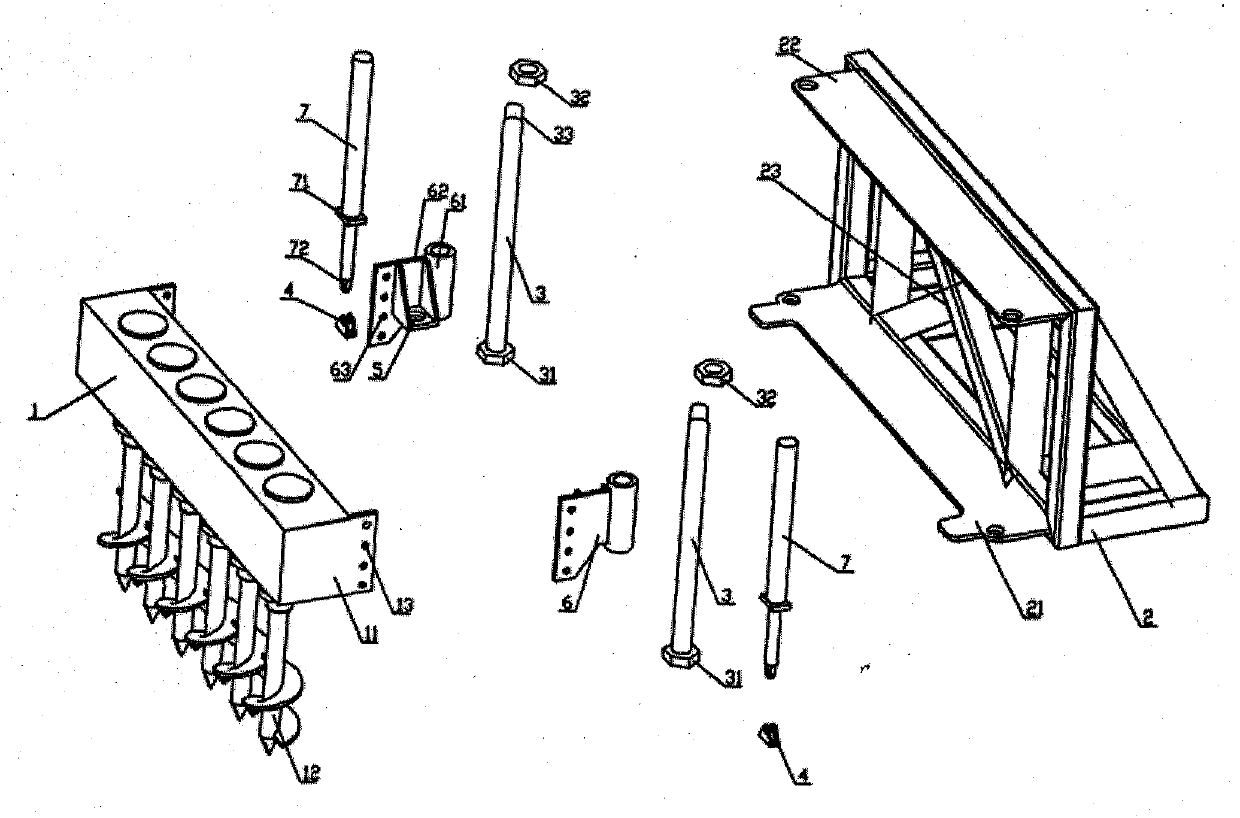

[0022] As the first embodiment of the cantilever vertical lifting system of the present invention, the frame 2 is provided with an upper plate-shaped structure 22 and a lower plate-shaped structure 21, and two guide rods 3 pass through the guide part 61 and the guide sleeve. 6 sliding connection, one end is fixedly connected with the lower plate structure 21, and the other end is fixedly connected with the upper plate structure 22. The guide rod 3 includes a bolt head 31, a threaded portion 33, and a nut 32. The guide rod passes through the through hole provided on the upper plate structure 22, the guide hole portion 61 of the guide sleeve 6, and the lower plate structure 21. The through hole, and then the nut 32 is screwed on the threaded part 33 to realize the fast connection between the guide rod 3 and the frame 2. There are two guide sleeves, and each guide sleeve 6 is provided with a connecting portion 62 and a guide hole portion 61 matched with the guide rod, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com