Transition socket for horizontal dimming motor of automobile headlights

A technology for automotive headlights and dimming motors, applied to circuits, electrical components, vehicle connectors, etc., can solve problems such as loose plug terminals and elastic structures, open circuit arcs, and sparks, so as to avoid the formation of open circuits and prevent the formation of Effect of short circuit, size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

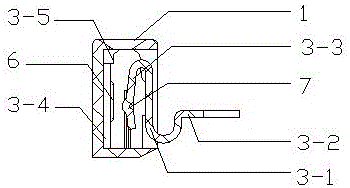

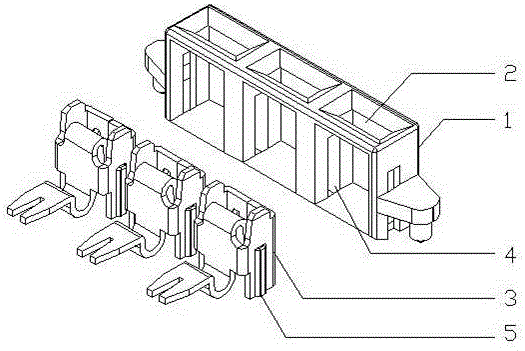

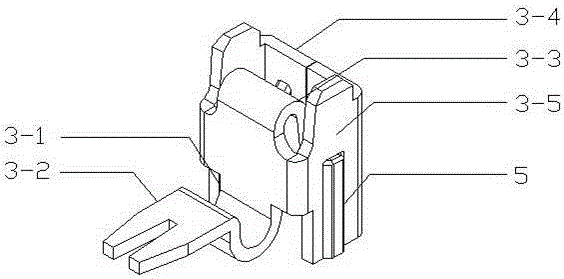

[0019] Such as Figures 1 to 7 As shown, the present invention is used for the horizontal dimming motor transition socket of automobile headlights, including a sheath socket 1, and the sheath socket 1 is a plastic sheath socket, and the plastic sheath socket can play the role of insulation protection, ensuring Electric safety. Insertion cavities 2 are provided in the sheath socket 1, and there are three insertion cavities 2, and the three insertion cavities 2 are evenly distributed in the sheath socket 1 to prevent short circuit connections between lines. Card slots 4 are provided on the left and right sides of the insertion cavity 2, openings are provided on the front and upper part of the insertion cavity 2, and a serpentine terminal 3 is installed correspondingly in each insertion cavity 2, and the serpentine terminal 3 is inserted into the insertion cavity from the front 2, the serpentine end 3 is a whole.

[0020] The serpentine terminal 3 includes a serpentine clip and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com