Mould releasing and combining device for large steel form and assembling method thereof

A mold clamping device and a technology of steel formwork, which are applied in the connection parts of formwork/formwork/work frame, processing of formwork, formwork/formwork/work frame, etc., can solve the problem of time-consuming, labor-intensive and low-efficiency mold removal and mold clamping. and other problems, to achieve the effect of simple structure, improved work efficiency and safe connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

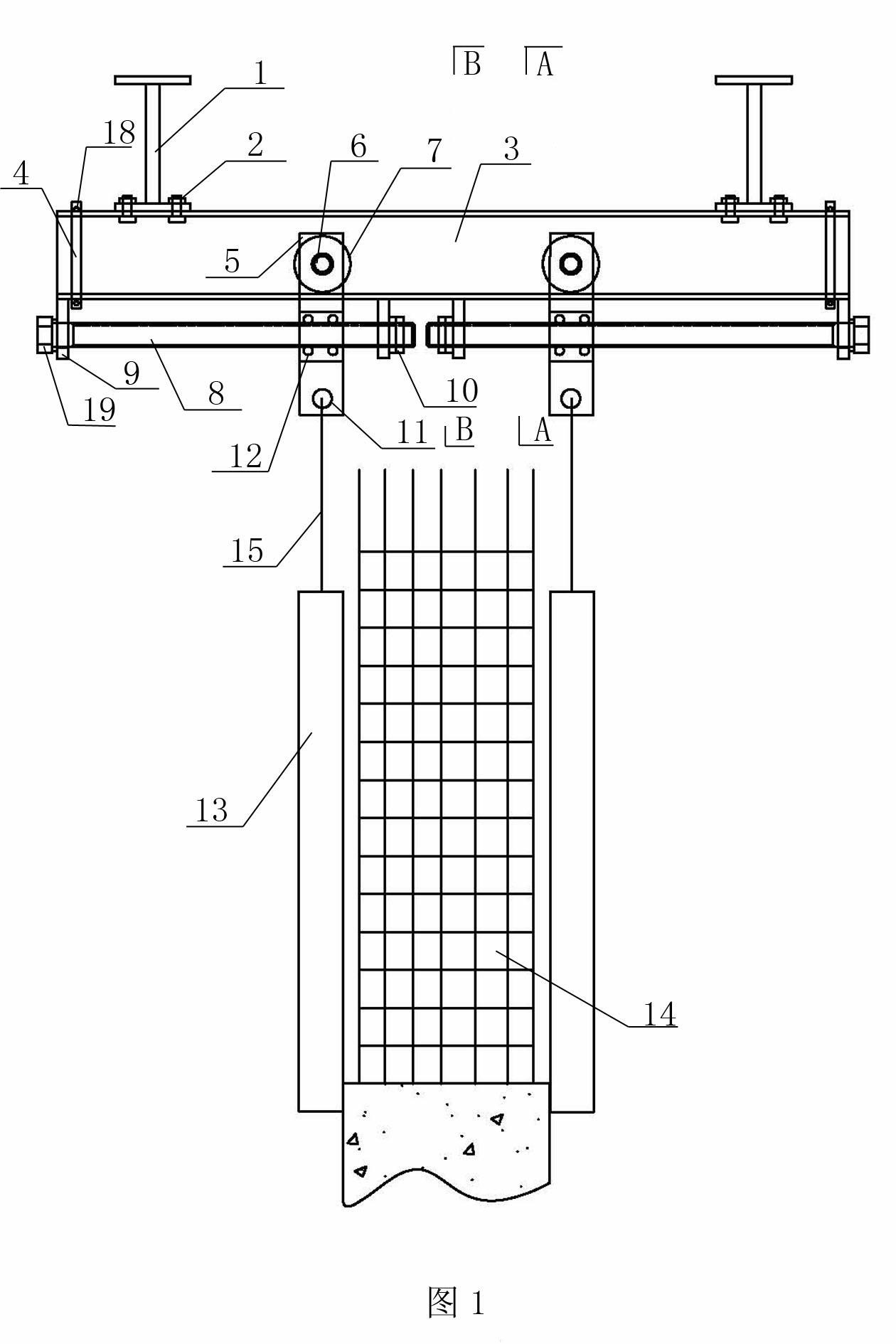

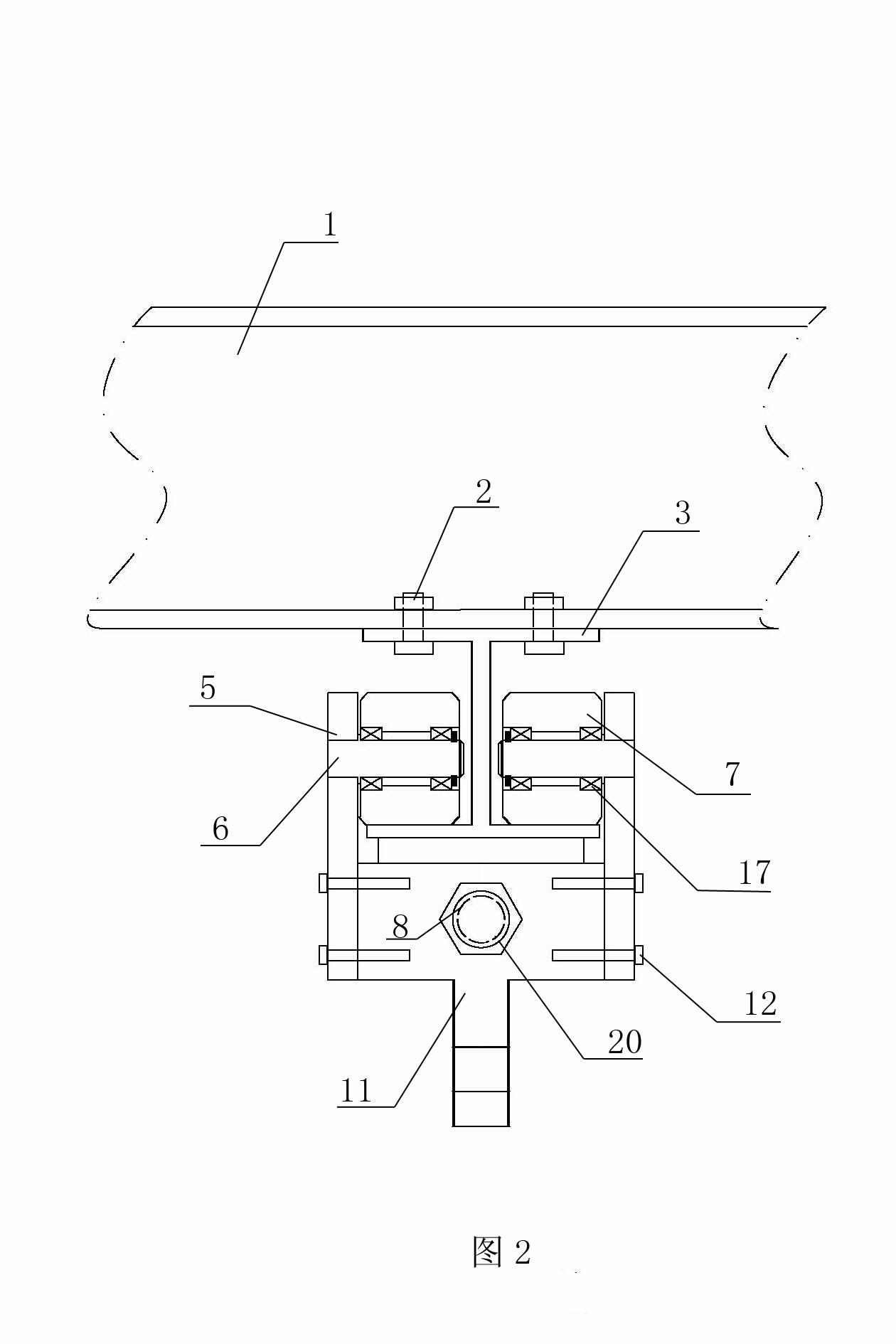

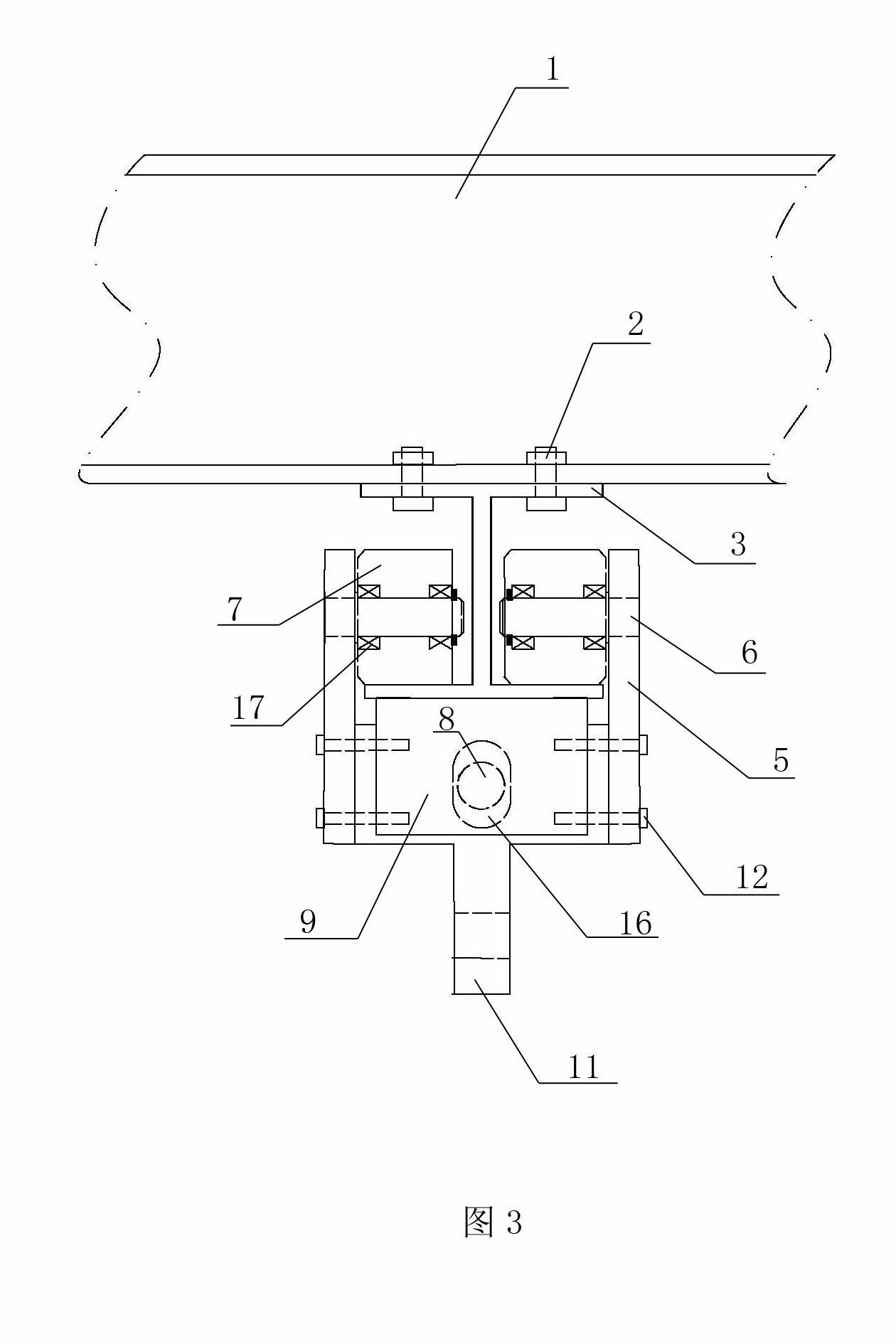

[0030] Examples see Figure 1 to Figure 4 As shown, a large steel formwork ejection and mold clamping device is connected to the lower chord section steel 1 of the steel platform through the connecting bolt I2, including a load-bearing rail 3 and at least one set of rollers 7, inverted T-shaped roller frames 11 and roller shafts 6 The pulley composed, the outer end of the horizontal side of the inverted T-shaped roller frame 11 is connected with a side plate 5, the side plate 5 is connected with a roller shaft 6, and the roller shaft 6 is equipped with a roller 7 through a bearing 17 , the rollers 7 are set on the load-bearing rail 3, and the outer end of the vertical side of the inverted T-shaped roller frame 11 is suspended with a pair of large steel formworks 13 parallel to each other through the suspension mechanism 15, and the large steel formwork 13 Located on both sides of the wall 14 to be poured, four screw fixing plates 9 with waist row holes 16 are respectively weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com