Steam-water mixer

A soda-water mixing and water-vapor technology, which is applied in the directions of fluid mixers, mixers, mixing methods, etc., can solve the problems of complex structure of the soda-water mixer, insufficient water-vapor mixing, and difficult air inhalation, etc., and achieves simple structure, use and maintenance. Convenient, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

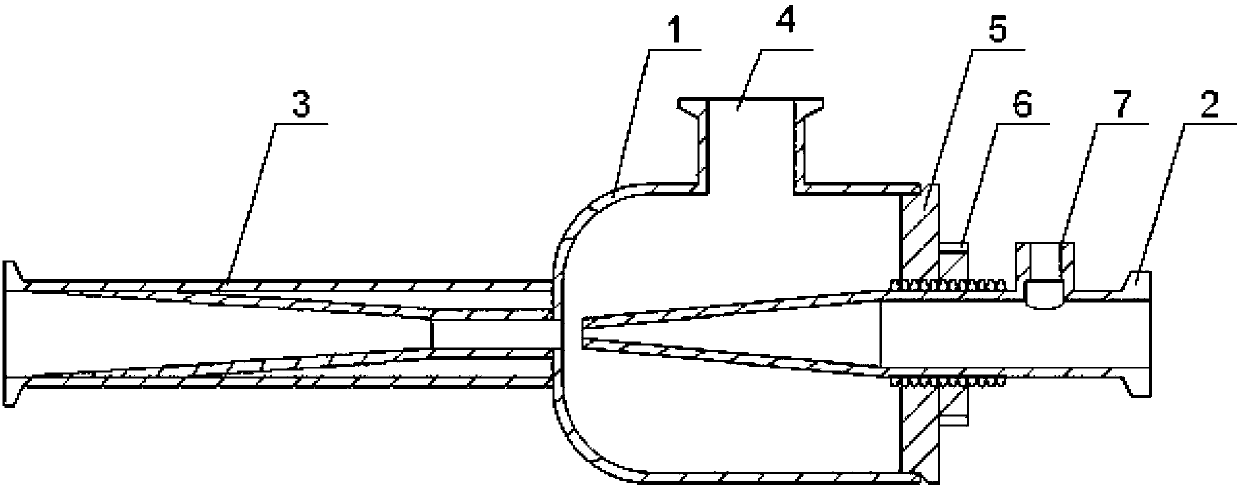

[0012] like figure 1 Said, a steam-water mixer, comprising a cylinder 1, a water inlet pipe 2 and a diffuser 3, the cylinder 1 is provided with an air inlet 4, the air inlet 4 communicates with the cylinder 1; the end of the cylinder 1 is installed with a tail flange 5. One end of the water inlet pipe 2 extends from the tail flange 5 into the cylinder body 1 and communicates with the cylinder body 1. The water inlet pipe 2 is provided with a thread at the connection with the tail flange 5. The water inlet pipe 2 is sealingly connected with the cylinder body 1; the diffuser 3 is communicated with the cylinder body 1, the water vapor inlet of the diffuser 3 is set in front of the water outlet of the water inlet pipe 2, and the water vapor inlet diameter of the diffuser 3 is larger than that of the water outlet of the water inlet pipe 2. The diameter is large, and the water inlet pipe 2 is provided with a pressure gauge 7 . The ratio of the water inlet diameter to the water outl...

Embodiment 2

[0014] like figure 1 Said, a steam-water mixer, comprising a cylinder 1, a water inlet pipe 2 and a diffuser 3, the cylinder 1 is provided with an air inlet 4, the air inlet 4 communicates with the cylinder 1; the end of the cylinder 1 is installed with a tail flange 5. One end of the water inlet pipe 2 extends from the tail flange 5 into the cylinder body 1 and communicates with the cylinder body 1. The water inlet pipe 2 is provided with a thread at the connection with the tail flange 5. The water inlet pipe 2 is sealingly connected with the cylinder body 1; the diffuser 3 is communicated with the cylinder body 1, the water vapor inlet of the diffuser 3 is set in front of the water outlet of the water inlet pipe 2, and the water vapor inlet diameter of the diffuser 3 is larger than that of the water outlet of the water inlet pipe 2. The diameter is large, and the water inlet pipe 2 is provided with a pressure gauge 7 . The ratio of the water inlet diameter to the water outl...

Embodiment 3

[0016] like figure 1 Said, a steam-water mixer, comprising a cylinder 1, a water inlet pipe 2 and a diffuser 3, the cylinder 1 is provided with an air inlet 4, the air inlet 4 communicates with the cylinder 1; the end of the cylinder 1 is installed with a tail flange 5. One end of the water inlet pipe 2 extends from the tail flange 5 into the cylinder body 1 and communicates with the cylinder body 1. The water inlet pipe 2 is provided with a thread at the connection with the tail flange 5. The water inlet pipe 2 is sealingly connected with the cylinder body 1; the diffuser 3 is communicated with the cylinder body 1, the water vapor inlet of the diffuser 3 is set in front of the water outlet of the water inlet pipe 2, and the water vapor inlet diameter of the diffuser 3 is larger than that of the water outlet of the water inlet pipe 2. The diameter is large, and the water inlet pipe 2 is provided with a pressure gauge 7 . The ratio of the water inlet diameter to the water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com