Online rapid pickling device and method for condenser in power plant

A technology of pickling device and condenser, applied in the direction of cleaning heat transfer device, flushing, lighting and heating equipment, etc., can solve the problems of not reaching cleaning concentration, waste of chemical cleaning agent, etc., to reduce usage and shorten cleaning time, reducing cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

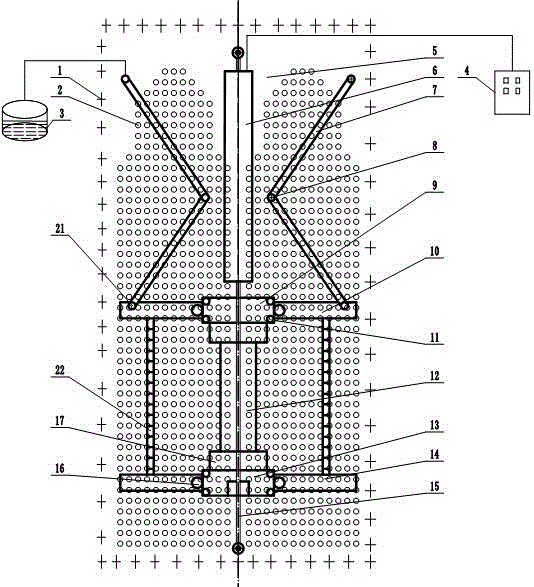

[0038] The technical solutions of the present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

[0039] Such as Figure 1 to Figure 4 As shown, an on-line rapid pickling device for condensers in a power plant includes a pickling liquid dispensing device 3 and a servo device 4 arranged outside the condenser water chamber 1, and the pickling liquid dispensing device 3 consists of a cleaning agent preparation tank , acid pump and valves, and can be configured with shaped products. An underwater positioning device for precise positioning and a quick filling device for injecting pickling liquid are installed in the condenser water chamber 1. The underwater positioning device depends on the technology. conditions, other lifting equipment with position sensors can also be used, and it is required to be able to operate underwater for a long time with a mechanical device with a repeat positioning accuracy of <2mm. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com