High-efficient and energy-saving aluminum rod mixing heating furnace

A high-efficiency, energy-saving, heating furnace technology, applied in lighting and heating equipment, furnaces, preheating costs, etc., can solve problems such as thermal energy waste, and achieve the effects of easy maintenance and repair, short preheating time, and shortening preheating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

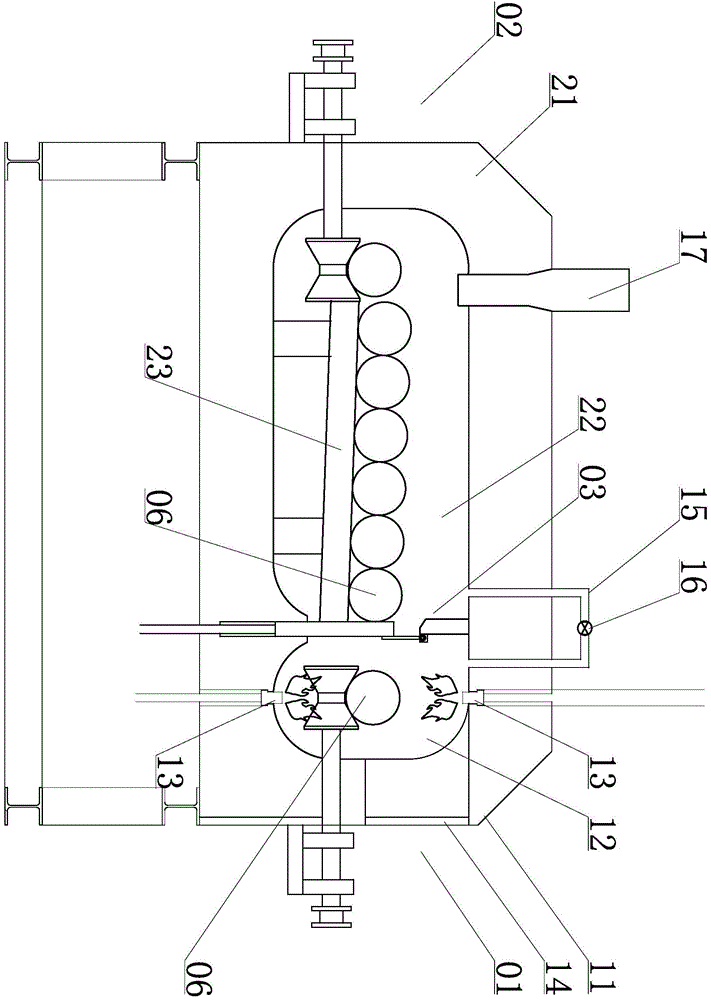

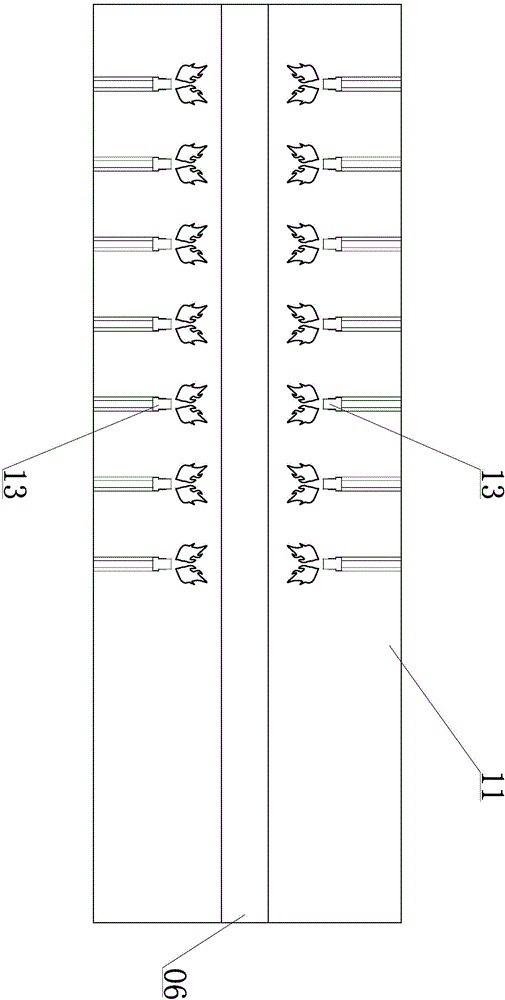

[0024] Such as Figure 1-2 As shown, a high-efficiency and energy-saving aluminum rod hybrid heating furnace includes a single-rod furnace 01 and a multi-rod furnace 02 integrated with the single-rod furnace 01. The single-rod furnace 01 includes a first furnace body 11 and a heating zone 12 provided in the first furnace body 11 , and spray guns 13 for heating a single aluminum rod 06 are arranged above and below the first furnace body 11 . The above-mentioned heating zone 12 is a chamber dedicated to adding the single rod furnace 01 . The multi-rod furnace 02 includes a second furnace body 21 integrated with the first furnace body 11 on one side of the first furnace body 11 , and a preheating zone 22 communicated with the heating zone 12 in the second furnace body 21 . The above-mentioned preheating zone 22 is a chamber dedicated to preheating a plurality of aluminum rods 06 arranged side by side. The main function of the preheating zone 22 is to use the residual heat of th...

Embodiment 2

[0027] Such as Figure 3-4 Shown, under the condition that does not change embodiment 1 structure. A heat exchanger 05 is provided between the exhaust pipe 17 and the spray gun 13 . The heat exchanger 05 includes an outer pipe body 52 communicating with the exhaust pipe 17 and an inner pipe body 51 communicating with the pipe body of the spray gun 13 to supply combustion-supporting air, and a device for controlling discharge is also arranged between the outer pipe body 52 and the exhaust gas. Valve 53. The function of the heat exchanger 05 is to use the waste heat discharged from the preheating zone 22 into the outer tube body 52 to preheat the combustion-supporting air supplied to the spray gun 13, so as to further realize the purpose of saving energy.

Embodiment 3

[0029] Such as Figure 5 Shown, under the condition that does not change embodiment 1 and embodiment 2 structure. Remove the baffle plate 03 and replace it with the structure of the notch 30 . Between the preheating zone 22 and the heating zone 12, there is a gap 30 corresponding to the diameter and width of the aluminum rod. When in use, the aluminum rod 06 can just pass through the width of the gap 30, and the diameter and width of the aluminum rod 06 is smaller than the width of the gap 30, which can effectively control the aluminum rod 06 to block the hot gas in the single rod furnace 01 and discharge it into the multi-rod furnace Timing within 02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com