Ceramic cooling roll

A cooling roller, ceramic technology, applied in sustainable manufacturing/processing, heat exchange equipment, climate sustainability, etc., to achieve the effect of reducing water consumption, improving wear resistance, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

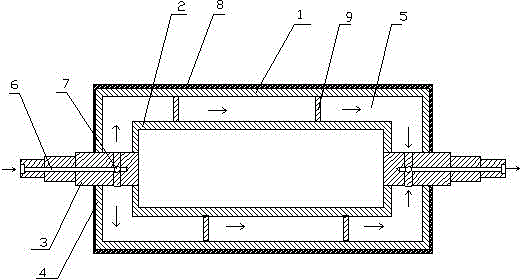

[0016] as attached figure 1 As shown, the ceramic cooling roller includes an outer roller 1 and an inner cylinder roller 2 arranged coaxially. The left and right ends of the inner cylinder roller are respectively provided with shaft heads 3, and the left and right shaft heads pass through the ends of the outer roller respectively. The sealing plate 4 forms a water cavity 5 between the outer roller and the inner cylinder roller, and a counterbore 6 parallel to the shaft head is provided at the axial center of the left and right shaft head ends, and the counterbore 6 is arranged toward the shaft head. The inside of the head extends to between the end of the outer roller and the end of the liner roller, and a number of through holes 7 that communicate with the counterbore are radially provided on the wall of the shaft head in this area.

[0017] When in use, the left and right shaft heads 3 are connected to the rotary seal joints respectively, and the water with pressure enters ...

Embodiment 2

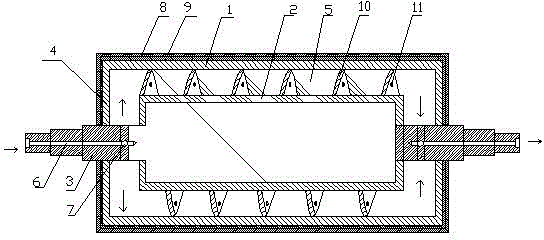

[0022] The ceramic cooling roller provided in Example 1 adds a ceramic layer 8 on the surface of the outer roller 1 to improve the corrosion resistance, wear resistance and anti-sticking performance of the cooling roller. The surface of the roller 1 has poor adhesion, and when used at high temperature for a long time, the ceramic layer 8 will easily form cracks and occur in broken and separated, which reduces the service life of the cooling roller.

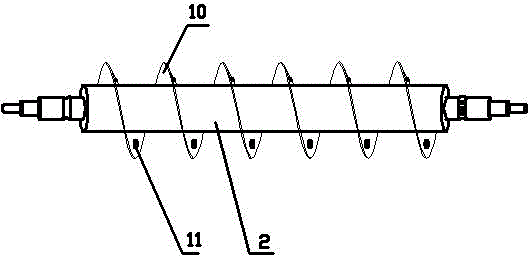

[0023] To solve this problem, the attached figure 2 As shown, in this embodiment, when making the ceramic layer 8, the surface of the outer roller 1 after cleaning and drying is now sprayed with a layer of nickel-aluminum alloy layer 9 by laser, and then sent into a drying room for curing and drying, and then coated with nickel-aluminum alloy A ceramic layer 8 is sprayed on the surface of the alloy layer 9 . The thickness of the nickel-aluminum alloy layer 9 is controlled to be between 10-20 wires. Since nickel-aluminum alloy h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com