Long stroke fracturing pump turbulator with dropping and connecting device

A fracturing pump and long-stroke technology, applied in the field of spoilers, can solve the problem of low stroke times and achieve the effect of reducing the deposition of solid particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

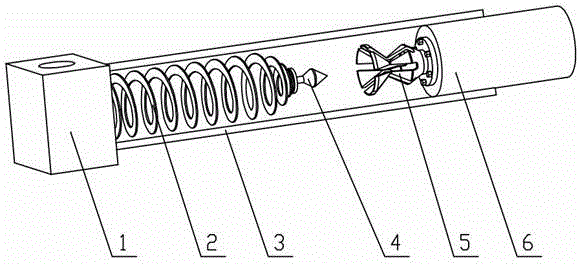

[0010] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0011] Such as figure 1 As shown, the valve box 1 and the pump cylinder 3 are connected by threads, the plunger 6 is arranged in the pump cylinder 3 , and the plunger 6 slides in the pump cylinder 3 . The spring 2 is a cylindrical helical spring with a rectangular section, and the spring 2 is arranged in the pump cylinder 3. One end of the spring 2 is connected to the valve box 1 with a bolt, and the other end of the spring 2 is installed with a plug 4 and connected with a bolt. The socket 5 is bolted to the end of the plunger 6 .

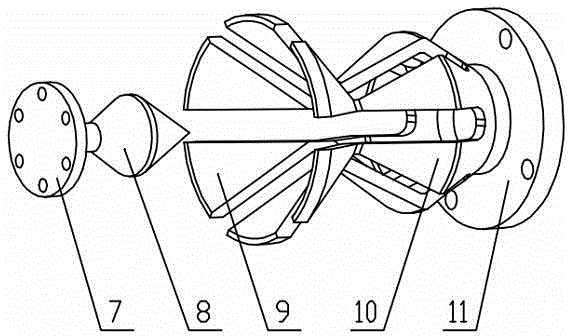

[0012] Such as figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com