A car air intake device

A technology of air intake device and automobile, which is applied in the direction of oil supply device, charging system, internal combustion piston engine, etc. It can solve problems such as uneven power distribution of cylinders, affecting the uniformity of vehicle power output, and uneven wear of cylinders, so as to promote Further development, simple structure, balanced power output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

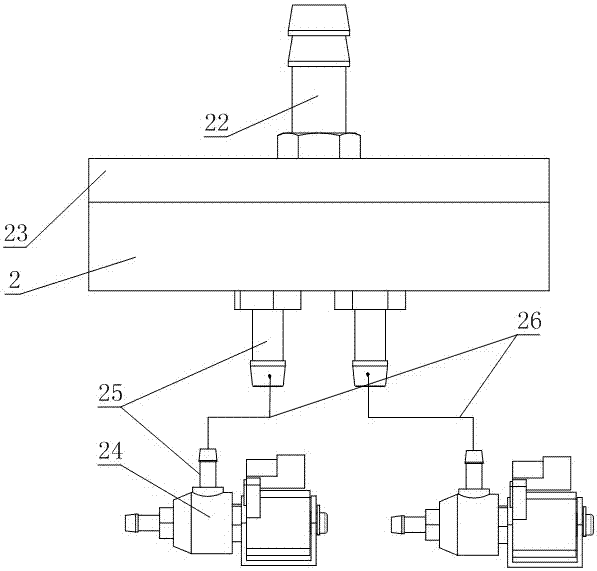

[0028] Such as Figure 1 to Figure 3 As shown, a kind of automobile air intake device, comprises distributing chamber 10, and described distributing chamber 10 is the sealed chamber surrounded by box body 2 and cover plate 23, and described distributing chamber 10 is connected with air inlet 22 and multiple Each air outlet 1 also includes a number of control parts equal to the number of air outlets 1, the shape of the distribution chamber 10 is centrally symmetrical, and the air outlets 1 are arranged symmetrically with respect to the air inlet 22;

[0029] A connection hose 26 is connected to the air outlet 1, and the other end of the connection hose 26 is connected to a cut-off valve body 24, and a fluid circulation channel is arranged in the cut-off valve body 24, and the connection hose 26 is connected to On the inlet end of the fluid communication channel, the control part and the isolation valve body 24 are used to control the communication status of each fluid communica...

Embodiment 2

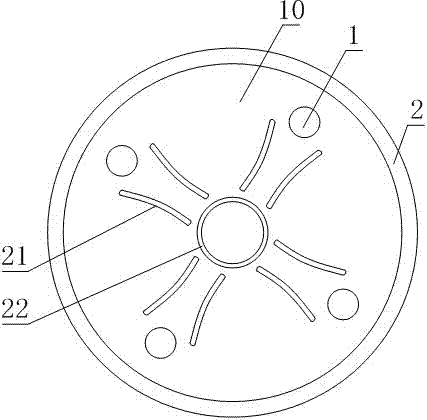

[0033] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As shown, as a simple arrangement of distribution chamber 10, air inlet 22 and air outlet 1, the box body 2 is in the shape of a cylinder, and the cover plate 23 is a plate-shaped structure connected with the box body 2 by threads or bolts. The distribution cavity 10 is the hollow part of the box body 2, the air inlet 22 is arranged at the center of the bottom surface of the box body 2, and the air outlet 1 is arranged on the bottom surface of the box body 2 and is annularly evenly distributed with respect to the air inlet 22.

[0034] In order to reduce the influence of the air outlets 1 on each other during the staggered communication process of the air outlets 1 after the air source enters the distribution chamber 10, the bottom surface of the box body 2 or the cover plate 23 is also provided with the number of groups and the air outlet 1 The number of deflectors 21 is eq...

Embodiment 3

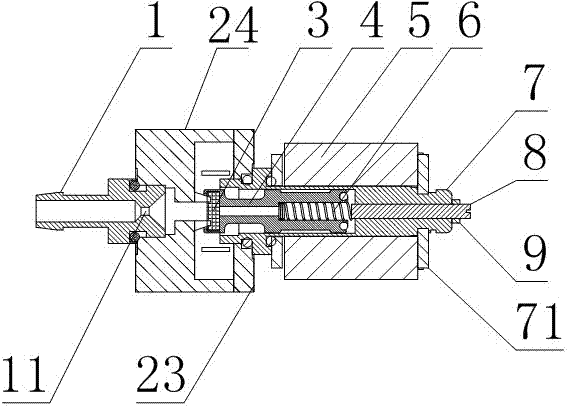

[0036] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As mentioned above, the control part includes a cut-off valve core 3, an iron rod 4, a spring 6, a connecting cylinder 7, a threaded post 8 and a coil 5. The ends are fixedly connected, and the iron rod 4 and the spring 6 are all located in the connecting cylinder 7, the connecting cylinder 7 is connected on the block valve body 24, the threaded column 8 is threadedly connected with the connecting cylinder 7, and the threaded column 8 goes deep into one end of the connecting cylinder 7 and The free end of the spring 6 is in contact, the axial direction of the threaded column 8 is parallel to the axial direction of the spring 6 , and the coil 5 is sleeved on the connecting cylinder 7 .

[0037] In this structure, the magnetic field generated after the coil 5 is energized acts on the iron rod 4 to form an electromagnet. When the power is not applied, the elastic stress of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com