Combined engine

A technology of engine and rotary engine, which is applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problems of energy consumption, and achieve the effect of uniform power output, ingenious design, and overall compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

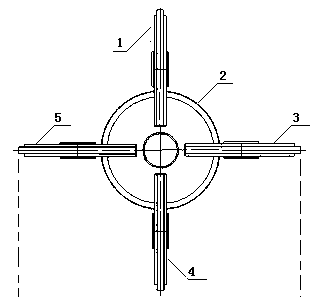

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0019] see figure 1 : A combined engine, its special feature is: the piston and the starter are composed of the piston rotary engine; the piston is composed of the circular crank 1 of the driving disc and the circular crank 2 of the driven disc (a part of the circle is missing), and the axes are mutually Vertical structural form, two circular cranks complement each other to move.

[0020] First, the piston rotates the engine. When the work starts, it is driven by the starter to rotate, and enters the following process:

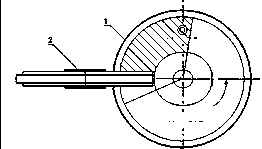

[0021] 1. Inhalation process, such as figure 2 As shown, the horizontal rotation crank is in the vacant position state at this moment.

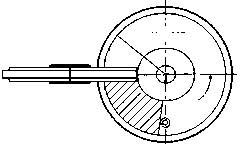

[0022] 2. Enter the fuel injection process. At this moment, the horizontal rotation crank is in the solid insertion position.

[0023] 3. During the ignition process, the horizontally rotating crank is in the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com