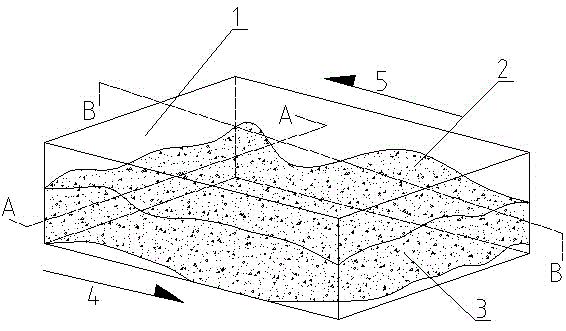

Method for enabling working face to pass through igneous rock intrusion area

An igneous rock and working face technology, applied in ground mining, earth-moving drilling, discharging machinery, etc., can solve problems such as low efficiency of simple drilling and chemical solution softening, waste of manpower, time, resources, and high safety hazards of blasting methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]The present invention is illustrated by taking the igneous rock intrusion area of Yipanqu Mountain in Yanya Coal Industry Co., Ltd. expansion area as an example.

[0038] General situation of the igneous rock intrusion area: the 8102 working face of Shan 4# layer in the expansion area of Tongmei Yanya Coal Industry Company is counted from the return air lane, the 1034m-1130m area of 210 lane is the roof lamprophyre intrusion area, and the roof lamprophyre intrusion area is from 1130m- 1234m lamprophyre intrudes into the middle of the coal seam, with a thickness of 0.2-1.3m, gradually thickening from south to north. The total length of the lamprophyre intrusion area is 200m. Lane 2102 is the roof lamprophyre intrusion area from 1742m to tail cut lane, Lane 5102 The area from 1194m-1260m is the base lamprophyre intrusion area, with a thickness of 0.1-0.4m, and the area from 1790m-1846m is the roof lamprophyre intrusion area. In the area of lamprophyre intrusion, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com