Method for improving gas production performance of anaerobic digestion by pretreating corn straw with low temperature water freezing

A technology for freezing pretreatment and corn stalks is applied in the field of anaerobic digestion of corn stalks and achieves the effects of low cost, mild operating conditions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 3 parts of corn stalks crushed to below 20 mesh, each part of corn stalks has a quality of 52g (in TS), add 100.68 milliliters of water to make it and the total mass of corn stalks contained in water (3.32 milliliters) be corn stalks 2 times the dry weight (104 ml). Store in airtight condition at 20°C for 1 day, 3 days and 5 days for pretreatment. At the same time, a group of untreated corn stalks without adding water was set as a control.

[0022] The pretreated corn stalks were mixed with 12g TS anaerobic sludge respectively, added to the anaerobic digestion reaction device, and tap water was added to reach 80% of the reaction device. Put the reactor filled with nitrogen gas and sealed after adding the materials into a shaker at 35°C, and shake. The anaerobic fermentation period is 75 days. The daily gas production volume was recorded by the drainage gas collection method, and the volume fraction of methane was measured every day to calculate the total methan...

Embodiment 2

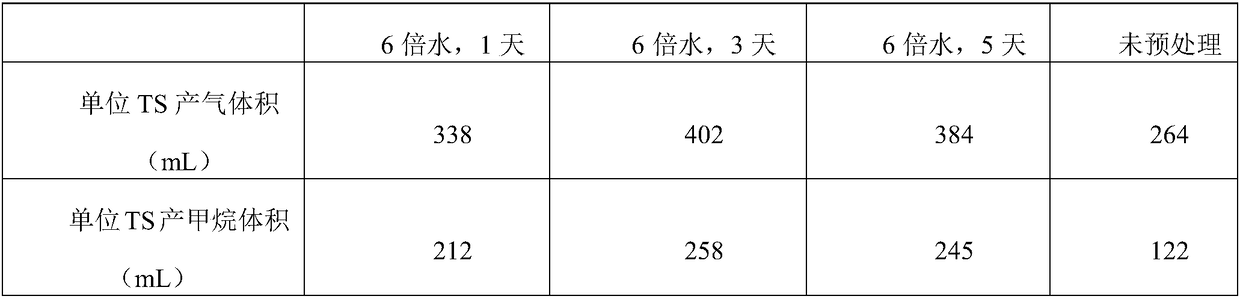

[0036] Weigh 3 parts of corn stalks crushed to below 20 mesh, each part of corn stalks has a weight of 52g (calculated in TS), add tap water 6 times its dry weight, add 308.68 ml of water to make it equal to the water contained in the corn stalks (3.32 ml) had a total mass of 6 times the dry weight of corn stover (312 ml). Sealed storage at -20°C for 1 day, 3 days and 5 days for pretreatment. At the same time, a group of untreated corn stalks without adding water was set as a control.

[0037] The pretreated corn stalks were mixed with 12g (TS) anaerobic sludge respectively, added to the anaerobic digestion reaction device, and tap water was added to 80% of the reaction device. Put the reactor filled with nitrogen gas and sealed after adding the materials into a shaker at 35°C, and shake. The anaerobic fermentation period is 75 days. The daily gas production volume was recorded by the drainage gas collection method, and the volume fraction of methane was measured every day ...

Embodiment 3

[0051] Weigh 3 parts of corn stalks crushed to below 20 mesh, each part of corn stalks has a weight of 52g (calculated in TS), add tap water 10 times its dry weight, and add 516.68 ml of water to make it equal to the water contained in the corn stalks. (3.32 ml) with a total mass of 10 times the dry weight of corn stover (520 ml). Store in airtight condition at 4°C for 1 day, 3 days and 5 days for pretreatment. At the same time, a group of untreated corn stalks without adding water was set as a control.

[0052] The pretreated corn stalks were mixed with 12g (TS) anaerobic sludge respectively, added to the anaerobic digestion reaction device, and tap water was added to 80% of the reaction device. Put the reactor filled with nitrogen gas and sealed after adding the materials into a shaker at 35°C, and shake. The anaerobic fermentation period is 75 days. The daily gas production volume was recorded by the drainage gas collection method, and the volume fraction of methane was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com