Preparation method of stress-discoloring photonic crystal fibers

A photonic crystal fiber and stress-changing technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve problems such as few reports, achieve fast and stable color change, fast and reversible structural color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Synthesis of highly oriented carbon nanotube arrays

[0027] Highly oriented carbon nanotube arrays grown by chemical vapor deposition (CVD) with a catalyst of Fe (1.2 nm) / Al 2 o 3 (3 nm) / Si, Al 2 o 3 and Fe are sequentially deposited on silicon wafers using electron beam evaporator, in which Al 2 o 3 layer as a buffer layer and Fe as a catalyst. Vinyl (90 cm 3 / min) as carbon source, hydrogen (30 cm 3 / min) and argon (400 cm 3 / min) was used as the carrier gas and grown in a tube furnace at 740 °C for ten minutes.

[0028] (2) Preparation of elastic fibers, taking polydimethylsiloxane (PDMS) as an example

[0029] Prepare PDMS precursor solution: Measure 10 g of elastomer and 1 g of curing agent and mix evenly. Ultrasonic dispersion is uniform, and vacuum is used to remove air bubbles. It was poured into a 1.5 mm diameter heat shrinkable tube and cured at 80 °C for 2 hours.

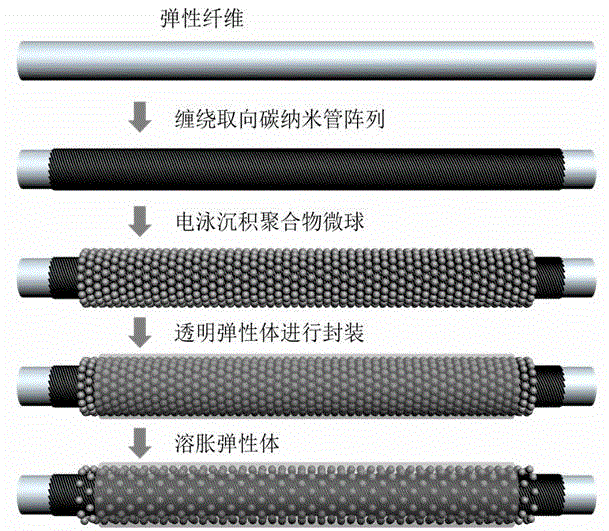

[0030] (3) Preparation of stress-changing photonic crystal fibers from green t...

Embodiment 2

[0033] (1) Synthesis of high arrays of aligned carbon nanotubes

[0034] Highly oriented carbon nanotube arrays grown by chemical vapor deposition (CVD) with a catalyst of Fe (1.0 nm) / Al 2 o 3 (10 nm) / Si, Al 2 o 3 and Fe are sequentially deposited on silicon wafers using electron beam evaporator, in which Al 2 o 3 layer as a buffer layer and Fe as a catalyst. Vinyl (30 cm 3 / min) as carbon source, hydrogen (90 cm 3 / min) and argon (400 cm 3 / min) was used as the carrier gas and grown in a tube furnace at 740 °C for fifteen minutes.

[0035] (2) Preparation of finer elastic fibers, taking polydimethylsiloxane (PDMS) as an example

[0036] Prepare PDMS precursor solution: Measure 5 g of elastomer and 0.75 g of curing agent and mix well. Ultrasonic dispersion is uniform, and vacuum is used to remove air bubbles. It was poured into a 0.8 mm diameter heat shrinkable tube and cured at 80 °C for 1.5 hours.

[0037] (3) Preparation of stress-changing photonic crystal fibers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com