A kind of low carbon olefin hydration process

A technology of carbon olefin hydration and low carbon olefin, which is applied in the field of low carbon olefin hydration process, and can solve the problem that stability has not been fundamentally solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

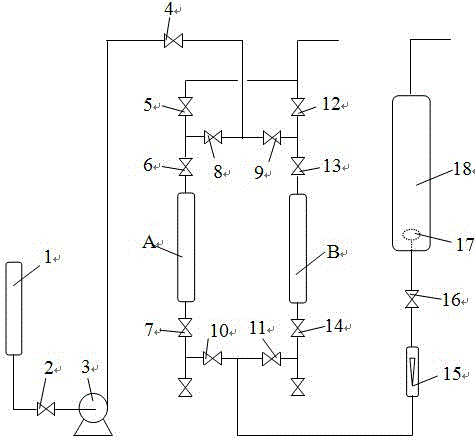

Image

Examples

Embodiment 1

[0021] In Example 1, the unmodified catalyst DNW-II strong acidic cation exchange resin (produced by Dandong Mingzhu Special Resin Co., Ltd.) was directly used. Embodiment 2 adopts the SO that zinc mass content is 2% 4 2- / ZnO modified DNW-Ⅱ strong acidic cation exchange resin catalyst. Embodiment 3 adopts the SO that zinc mass content is 8% 4 2- / ZnO modified DNW-Ⅱ strong acidic cation exchange resin catalyst. The feeding methods of Examples 1-3 are all extrusion feeding by water, and n-butene and propylene are respectively used as raw materials. The reaction conditions are shown in Table 1, and the analysis results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com