Simple and efficient feeding mechanism of pin-type microphone head

A feeding mechanism and microphone technology, applied in the direction of electrical components, sensors, etc., can solve the problems of low feeding efficiency, achieve high-efficiency feeding, improve detection and sorting efficiency, and continue feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

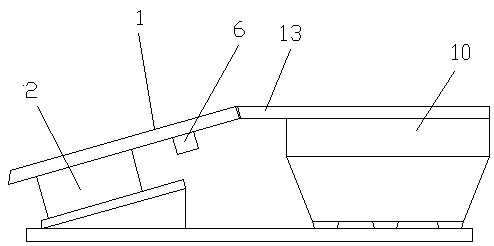

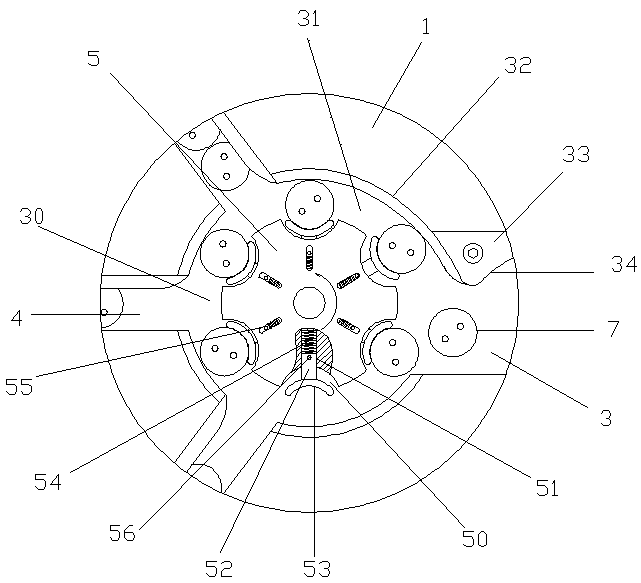

[0023] Such as figure 1 with figure 2 The simple and high-efficiency feeding mechanism of a needle-type microphone shown includes a distribution tray 1 and a linear vibrator 2 arranged at the bottom of the distribution tray. There are three distributing troughs 4 on the left end of the pan, the distributing pan 1 is distributed obliquely, the inclination angle is 20°, the feeding end of the total feeding chute is located at the upper end of the distributing pan, and the discharging end of the distributing trough is located at the lower end of the distributing pan A circular buffer zone 30 is provided between the distribution tank 4 and the total feed tank 3, the center of the circular buffer zone 30 is provided with a rotating block 5, and the bottom of the distribution tray 1 is provided with a speed-regulating motor that drives the rotating block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com