A milling machine capable of separating asphalt and gravel

A milling machine and separation mechanism technology, which is applied in the field of milling machines, can solve the problems affecting the laying effect, the change of the proportion of stones and asphalt, etc., and achieve the effect of saving workpiece space, reducing costs and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

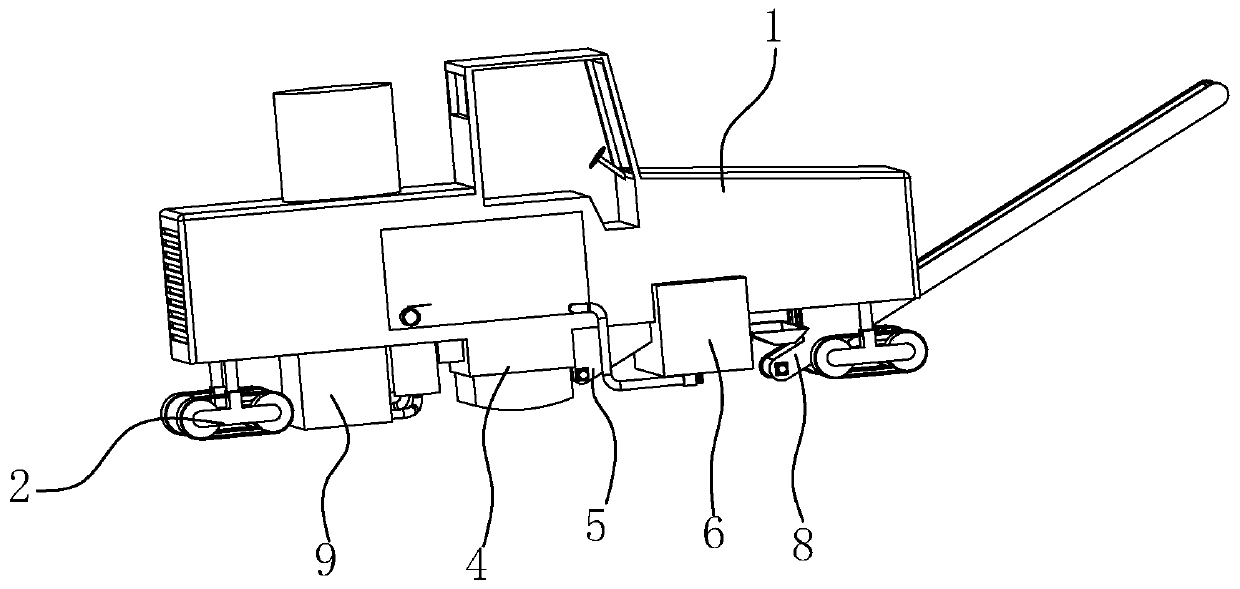

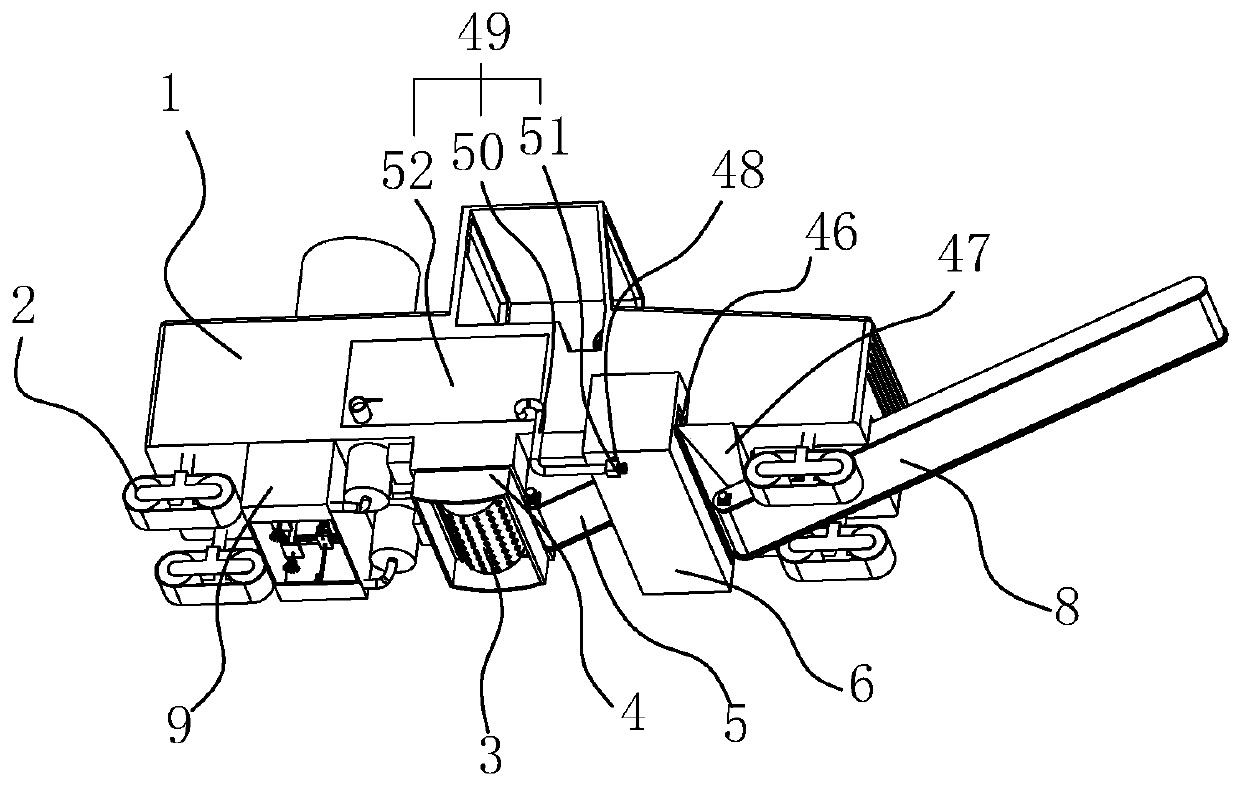

[0042] A milling machine that separates asphalt and gravel, such as figure 1 and figure 2 As shown, including a car body 1, a support wheel 2 for supporting the car body 1 is provided at the bottom of the car body 1, the support and walking of the car body 1 can be realized by the support wheels 2, and a support wheel 2 for supporting the car body 1 is provided at the bottom of the car body 1. The milling assembly 3 for cutting damaged asphalt pavement, the outer cover of the milling assembly 3 is provided with a dust-proof mechanism 4 for preventing gravel from splashing out, and the discharge side of the milling assembly 3 is provided with a device for receiving and conveying waste materials The first conveying assembly 5 of the first conveying assembly 5 is provided with a separation mechanism 6 for separating asphalt and stones at the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com