Method for cladding energetic materials

A coating material and coating technology, applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive composition, nitroalkane composition, ammonium perchlorate composition, etc., can solve complex operation, application limitations, Environmental pollution and other problems, to achieve the effect of low and controllable conditions, strong solubility, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for coating an energetic material in this embodiment includes the following steps:

[0031] First, dissolve the fluororubber in ethyl acetate to form a coating material solution with a concentration of 5‰, measure 20ml of the coating material solution, then add 2g RDX to the coating material solution to form a suspension, and stir the suspension After 30 minutes, pour the suspension into a pressure vessel with a temperature of 15°C, seal it tightly, and inject CO into the pressure vessel at a flow rate of 2kg / h. 2 , when the pressure in the pressure vessel reaches 5MPa, stop feeding CO 2 , after 10 minutes of heat preservation and pressure holding, the CO 2 Ventilation was carried out for 10 minutes, and finally the pressure of the pressure vessel was released to normal pressure to obtain a 5% fluororubber-coated RDXG product.

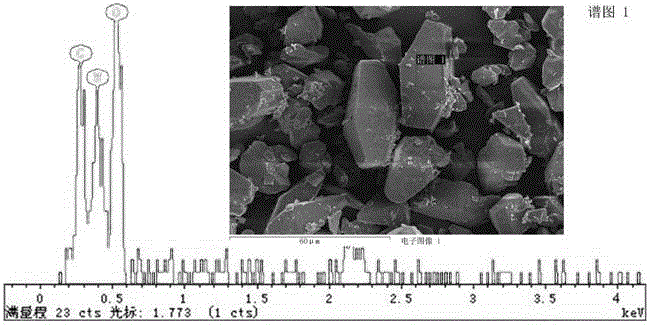

[0032] from figure 1 with figure 2 It can be seen that the crystal surface of the RDXG after the fluororubber coating in Example ...

Embodiment 2

[0034] A method for coating an energetic material in this embodiment includes the following steps:

[0035] First, dissolve fluororubber in methanol to prepare a coating material solution with a concentration of 1‰, measure 20ml of the coating material solution, and then add 2g of hexanitrohexaazaisowurtzitane to the coating material solution to form a suspension , Stir the suspension for 30min, pour the suspension into a pressure vessel with a temperature of 14°C, seal it, and pass CO2 into the pressure vessel at a flow rate of 3kg / h 2 , when the pressure in the pressure vessel reaches 5MPa, stop feeding CO 2 , after 10 minutes of heat preservation and pressure holding, the CO 2 Ventilation was performed for 15 minutes, and finally the pressure of the pressure vessel was released to normal pressure to obtain a fluororubber-coated hexanitrohexaazaisowurtzitane product with a mass fraction of 1%.

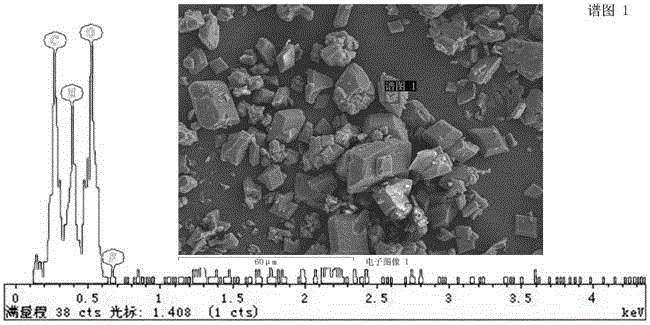

[0036] from image 3 with Figure 4 It can be seen that the crystal surface ...

Embodiment 3

[0041] A method for coating an energetic material in this embodiment includes the following steps:

[0042] First, dissolve fluororubber in methanol to form a coating material solution with a concentration of 3.1‰, measure 20ml of the coating material solution, then add 2g of aluminum hydride to the coating material solution to form a suspension, and stir the suspension for 30 minutes. Pour the suspension into a pressure vessel with a temperature of 14.5°C, seal it tightly, and feed CO into the pressure vessel at a flow rate of 2.5kg / h 2 , when the pressure in the pressure vessel reaches 5MPa, stop feeding CO 2 , after 10 minutes of heat preservation and pressure holding, the CO 2 Air was exchanged for 13 minutes, and finally the pressure of the pressure vessel was released to normal pressure to obtain a fluorine rubber-coated aluminum hydride product with a mass fraction of 3%.

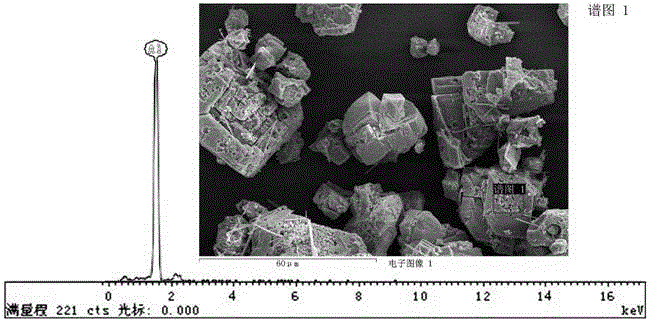

[0043] from Figure 5 with Image 6It can be seen that the crystal edges and corners of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com