Method for preparing graphene

A graphene and precursor technology, applied in the field of graphene preparation, can solve the problems of affecting product quality and low degree of graphitization of biomass materials, and achieve the effect of strong electronegativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a kind of preparation method of graphene, comprises the following steps:

[0038] A) mixing biomass material, anionic surfactant and water, and performing a hydrothermal reaction to obtain a precursor, the temperature of the hydrothermal reaction is 150-250°C, and the time of the hydrothermal reaction is 1-24 hours;

[0039] B) mixing the metal catalyst with the precursor obtained in step A) to obtain a precursor containing the metal catalyst;

[0040] C) heating the metal catalyst-containing precursor obtained in step B) to obtain graphene.

[0041] The degree of graphitization of the graphene obtained by the preparation method provided by the invention is relatively high, and the quality of the obtained product is relatively good.

[0042] In the present invention, the biomass material, anionic surfactant and water are mixed, and a hydrothermal reaction is carried out to obtain a precursor. In the present invention, the biomass material, anioni...

Embodiment 1

[0064] Take 10g of glucose and 1g of sodium lauryl sulfate, add it to 150ml of hydrofluoric acid aqueous solution with a concentration of 0.01mol / l, then ultrasonicate the obtained glucose solution for 5 minutes, pour it into a reaction kettle, and carry out hydrothermal treatment at 180°C After reacting for 10 hours, dry at 80°C to obtain a precursor.

[0065] Take 1g of precursor, add it to 100ml of solution containing 1g of potassium ferricyanide, ultrasonicate for 15 minutes, let stand for 4h, filter, and dry the filtered solid at 80°C to obtain iron ion-containing precursor. According to the mass ratio of iron ion-containing precursor to KOH, it is mixed with KOH at a ratio of 1:1, dried, and calcined at 1000°C for 2h under an inert atmosphere with a heating rate of 5°C / min. Wash with hydrochloric acid, filter, and dry the filtered solid at 120°C to obtain porous graphene.

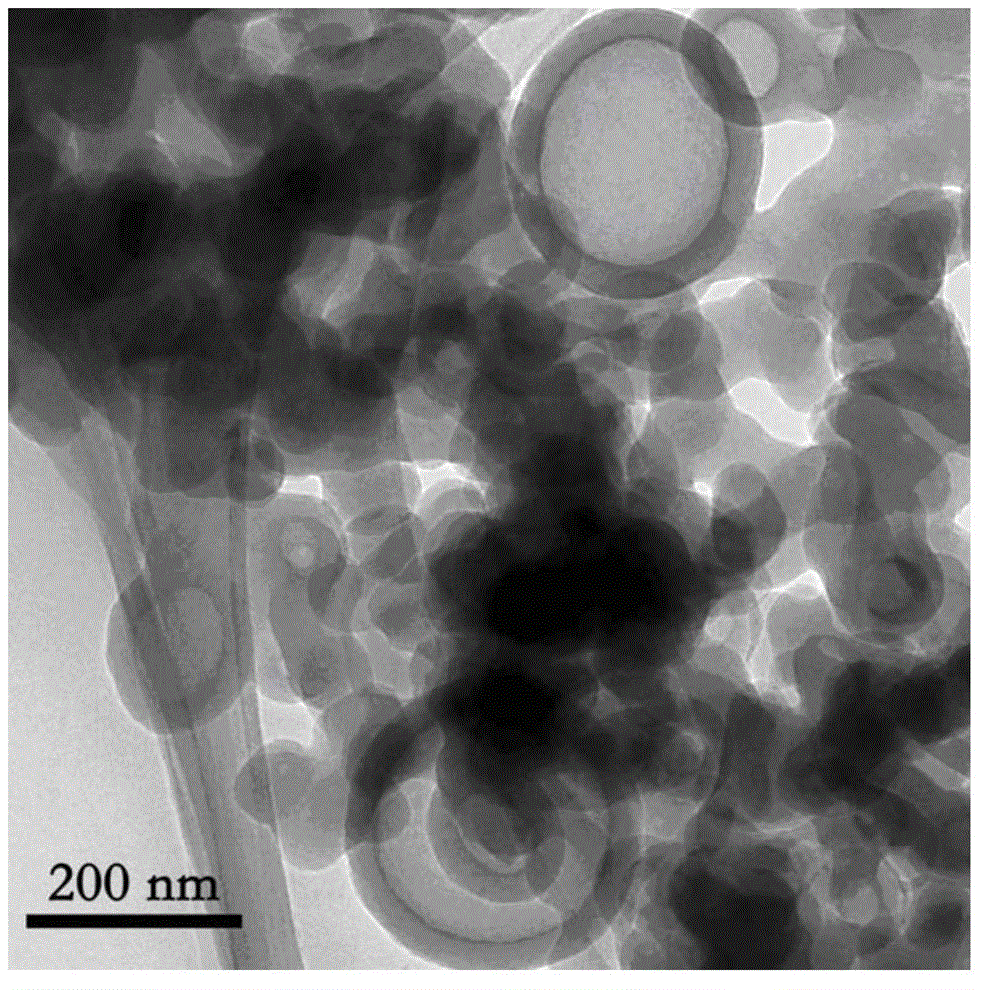

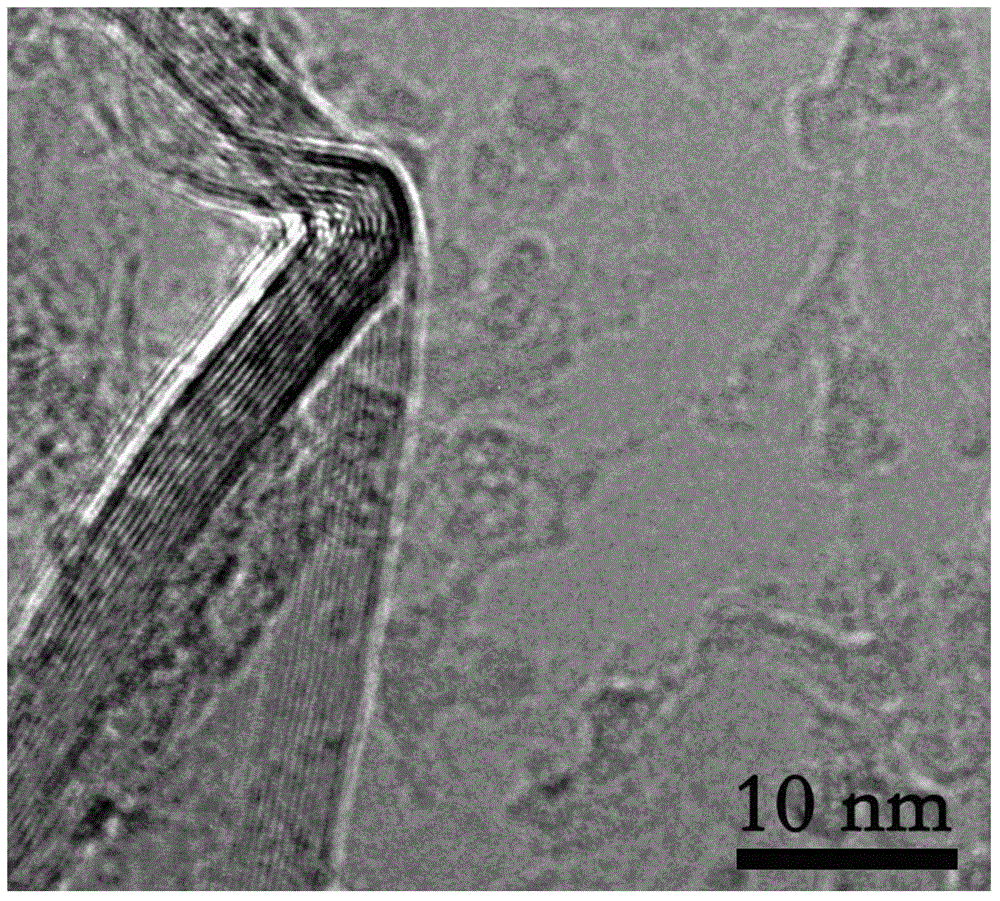

[0066] The present invention has carried out transmission electron microscope detection (TEM) to ...

Embodiment 2

[0073]Take 20g of glucose and 1g of sodium dodecylbenzenesulfonate, add 150ml of deionized water, then ultrasonicate the resulting glucose solution for 5 minutes, pour it into a reaction kettle, and carry out hydrothermal reaction at 150°C. After 6 hours of reaction, 80 °C drying to obtain the precursor.

[0074] Take 1 g of the precursor, add it to 100 ml of a solution containing 0.5 g of ferric chloride, ultrasonicate for 15 minutes, let stand for 10 h, filter, and dry the filtered solid at 80° C. to obtain a precursor containing iron ions. Calcined at 800°C for 2 hours under an inert atmosphere with a heating rate of 5°C / min. The calcined product was washed with 1 mol / L hydrochloric acid, filtered, and the filtered solid was dried at 120°C to obtain graphene.

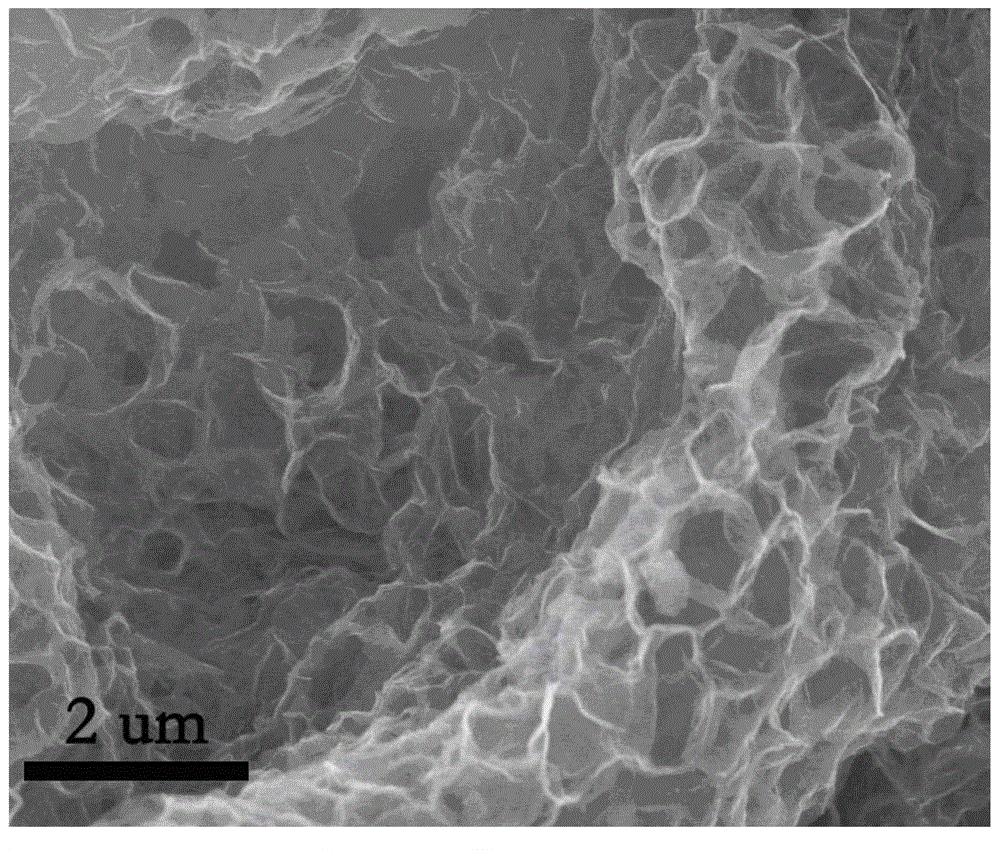

[0075] The present invention has carried out scanning electron microscope detection (SEM) to the precursor that present embodiment obtains, and the result is as follows Figure 7 as shown, Figure 7 The SEM figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com