Automatic production line for forming to sintering of ferrite magnetic steel and implementation method

An automatic production line, ferrite magnet technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of long production cycle, low production efficiency, poor labor conditions, etc., to achieve small production area, production The effect of short cycle time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

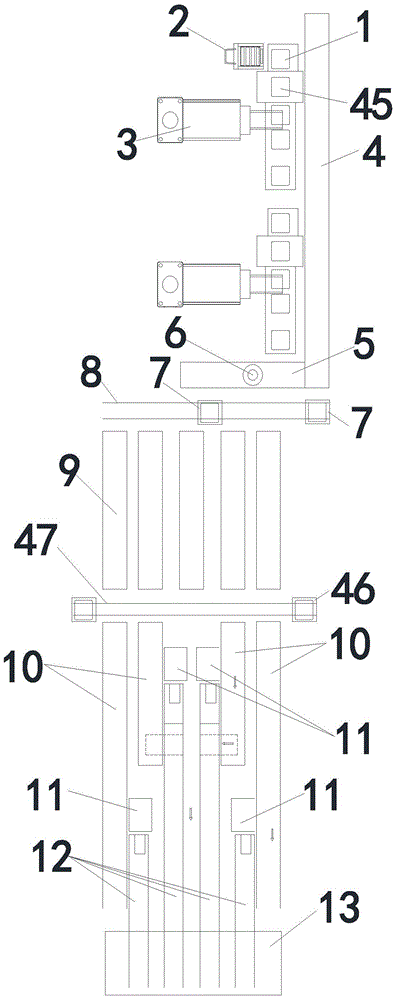

[0048] Such as Figure 1~6 As shown, an automatic production line from molding to sintering of ferrite magnets includes several empty pusher warehouses 1, empty pusher trolleys 2 are placed on the side of the empty pusher warehouses 1, and a Get embryo discharging machine and press 3, below press 3 is conveyer belt 4, image conveyer belt 5 is connected with conveyer belt 4 outlet end, image conveyer belt 5 is provided with image recognition device 6, the image recognition device in the present embodiment 6 is the product that buys on the market, and image conveyer belt 5 sides are provided with some first lift trolleys 7, and the bottom of first lift trolley 7 is provided with first slide rail 8, and first lift trolley 7 sides are provided with some A rough conveyor belt 9, a number of second lifting trolleys 46 are arranged at the outlet end of the blank conveyor belt 9, a second slide rail 47 is arranged at the bottom of the second lifting platform 46, and several kiln entra...

Embodiment 2

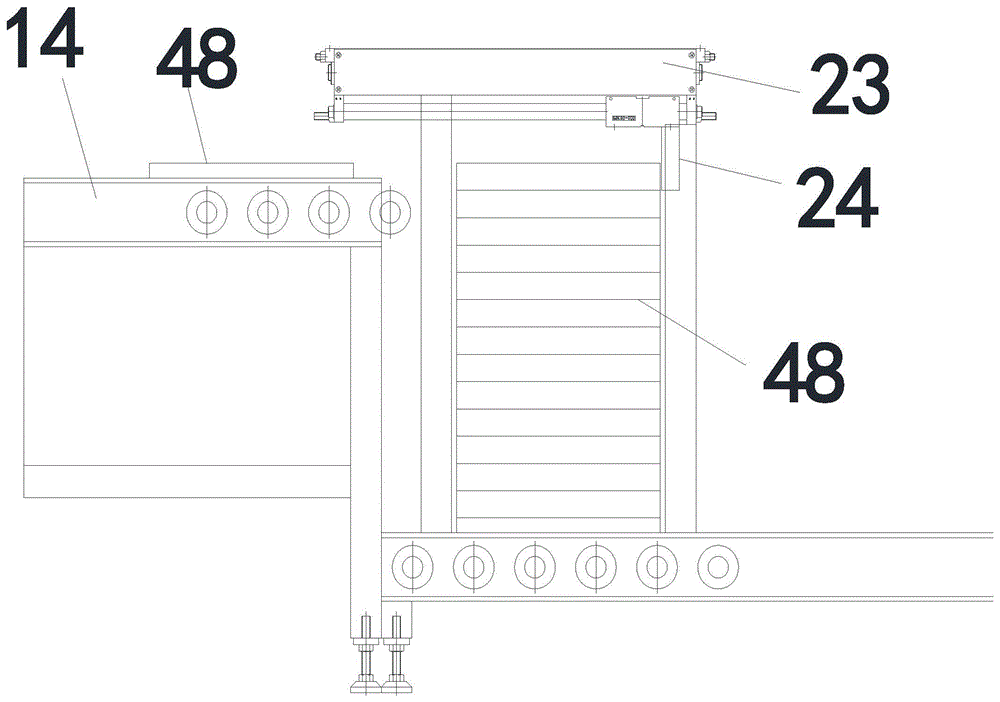

[0067] The difference between this embodiment and Embodiment 1 is that the length of the push rod 24 in this embodiment is greater than the width of the empty push plate 48, and the thickness of the push rod 24 is smaller than the thickness of the empty push plate 48. The design purpose is to use a smaller Force, the empty push pedal 48 is released correctly; The push rod 24 front is the empty push pedal waiting area 14, prepares for follow-up procedure; Caster 17 is provided with four, and caster 17 is universal wheel, convenient transfer; For forward and reverse rotation motor, realize the lifting of empty push plate 48.

[0068] The wobble plate positioning mechanism also includes an "L"-shaped clamping block, and the left clamping cylinder 29 and the right clamping cylinder 30 are respectively connected with an "L"-shaped clamping block, which can better clamp the empty push plate 48; the powder spreading device 31 includes The shell has several through holes on the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com