Pillow type packaging machine with ultra-short paper feeding path

A technology of pillow packaging machine and paper feeding mechanism, which is applied in the directions of packaging, transportation packaging, transportation and packaging, etc. It can solve the problems of affecting packaging quality, waste, stretching deformation, etc., shorten the paper feeding route, improve utilization rate, Cutting Accurate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

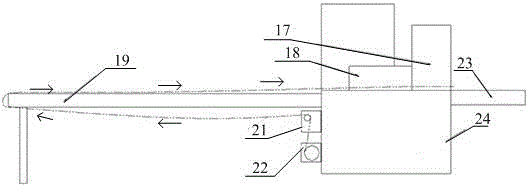

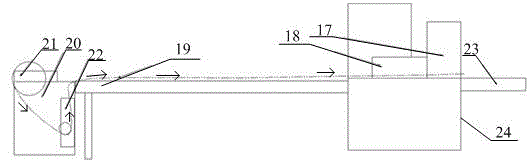

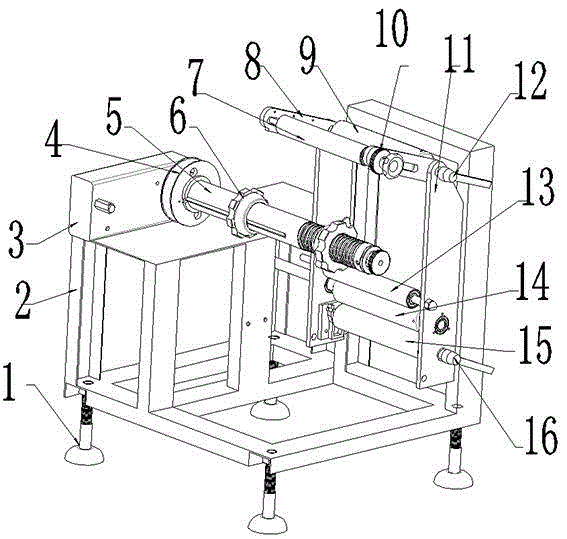

[0017] attached Figure 2-3 It is a specific embodiment of the present invention. The pillow packaging machine of the invention with a very short paper-feeding circuit comprises a frame 24, a knife sealing mechanism 17, a middle sealing mechanism 18, a tailstock 19, and an output mechanism 23, and is characterized in that: the rear end of the tailstock 19 is equipped with The paper supporting and moving mechanism assembly 20, the described paper supporting and moving mechanism assembly 20 is composed of the assembly frame 2, the paper supporting mechanism 21 and the paper moving mechanism 22, the paper supporting mechanism includes the paper supporting seat 3 and the paper moving cylinder 5, The paper supporting base 3 is fixed on the top of the assembly frame 2, and the paper feeding cylinder 5 is fixed on the paper supporting base 3. One end of the paper feeding cylinder 5 is fixed with a brake wheel 4, and a pressing wheel 6 is also installed. The above-mentioned paper-fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com