Image forming apparatus and a paper feeding apparatus for the same

一种成像装置、辊子的技术,应用在应用电荷图形的电记录工艺、应用电荷图形的电记录工艺的设备、运输和包装等方向,能够解决增加生产成本、增加部件数量、增加装置尺寸等问题,达到操作均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Matters defined in the description, such as detailed structure and elements, are helpful for a comprehensive understanding of the embodiments of the present invention. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted for clarity and conciseness.

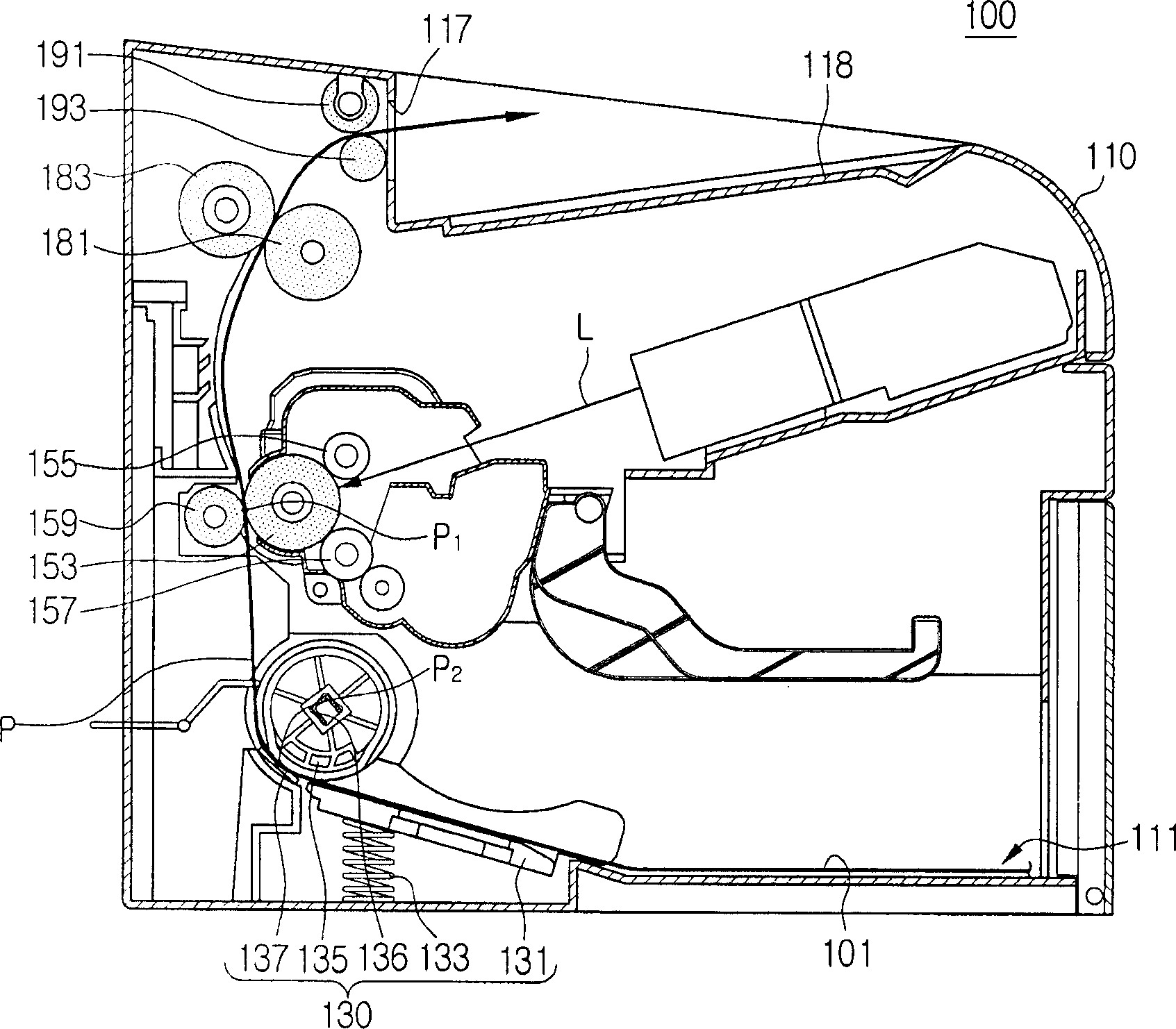

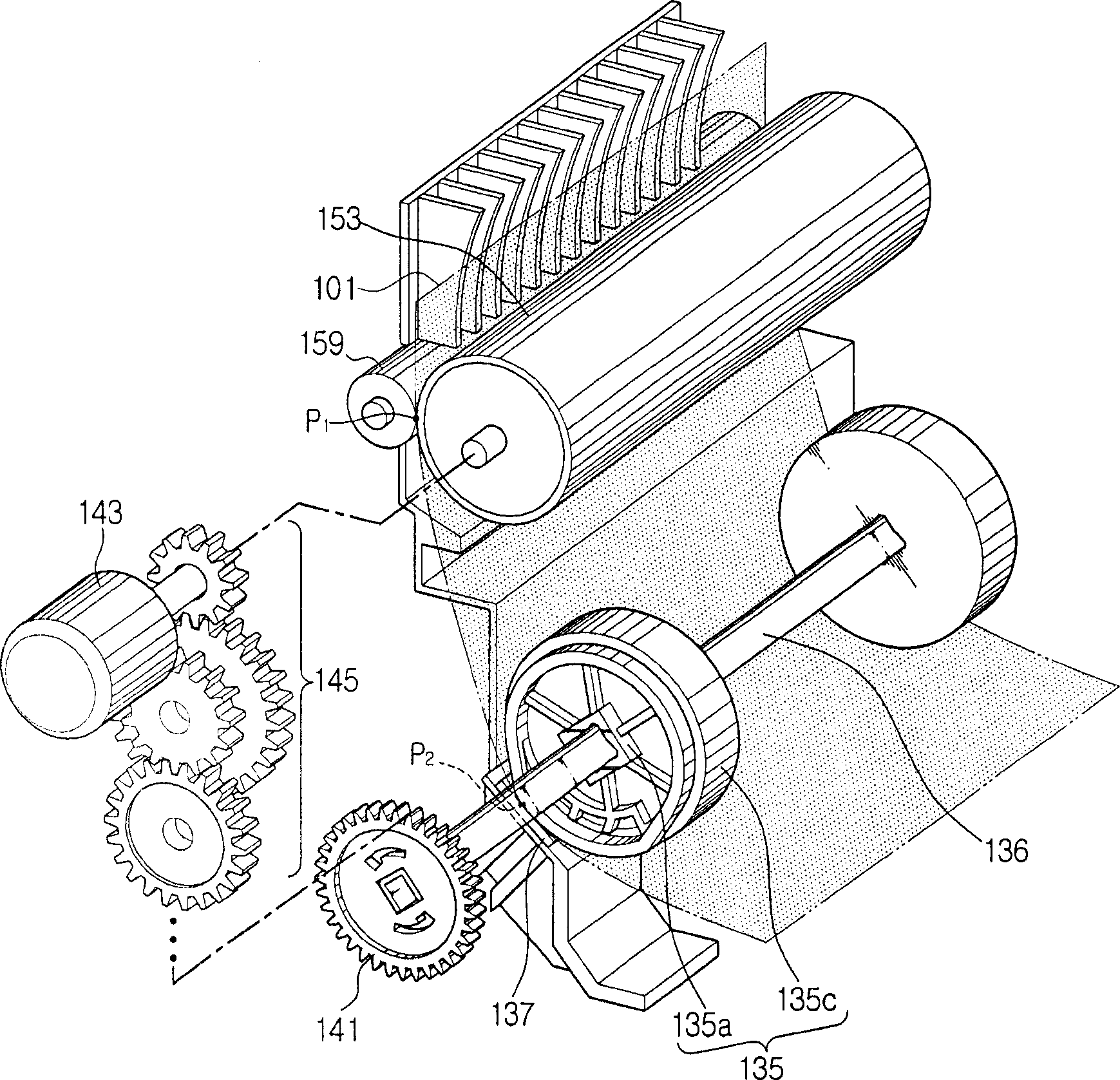

[0038] Refer to attached figure 2 , the paper feeding part 111 is formed on the inner surface of the bottom of the main body 110 . A knockup plate 131 for stacking a plurality of sheets of paper thereon is provided at the paper feeding section 111 . The biasing element 133 is located between the strike plate 131 and the main body 110 . Since the pickup roller 135 is rotated, the paper 101 stacked on the impact plate 131 is picked up one by one by the friction generated by the friction pad 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com