A digital printing magnetic composite sheet material with personality and an installing method

A magnetic composite material, digital printing technology, applied in chemical instruments and methods, synthetic resin layered products, hydraulic material layered products, etc., can solve the problems of less customer selectivity, lack of personality, single color, etc. Flat effect, environmentally friendly construction work, full paint film without orange peel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

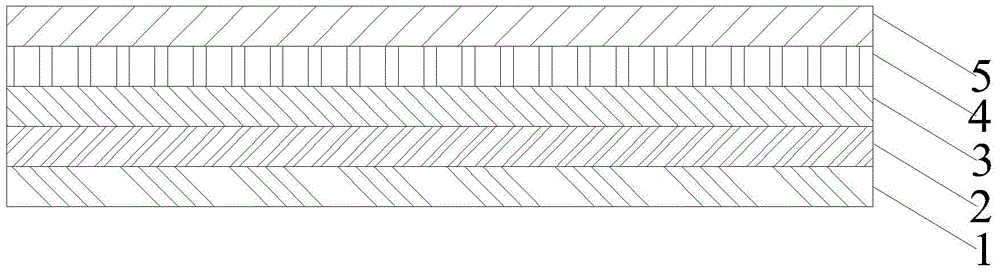

[0030] Such as figure 1 The shown embodiment individualized digital printing magnetic composite board comprises a magnetic composite material layer 1, a substrate layer 2 disposed on the magnetic composite material layer 1, a UV paint adhesion layer 3 disposed on the substrate layer 2, a UV paint adhesion layer disposed on the magnetic composite material layer 1, The UV printing ink layer 4 on the UV paint adhesion layer 3 , and the wear-resistant UV paint protection layer 5 arranged on the UV printing ink layer 4 . This embodiment adopts the above structure, and utilizes the main characteristics of UV paint (printing personalized digital printing layout after strong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com