A self-propelled multifunctional straw harvesting and pulverizing machine

A pulverizer and multi-functional technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of high soil and impurity content in straw, large power consumption, and serious leakage of materials, so as to achieve harvesting and harvesting. Convenient reuse, high efficiency, increase the effect of banning straw burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

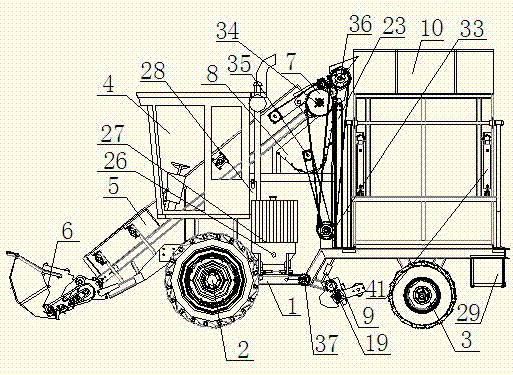

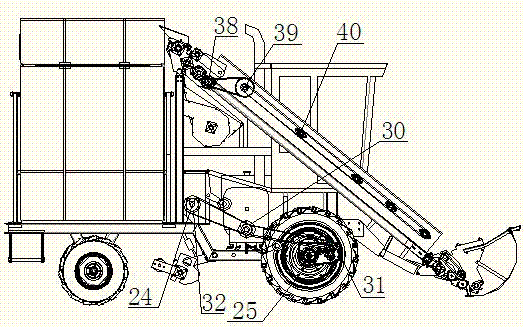

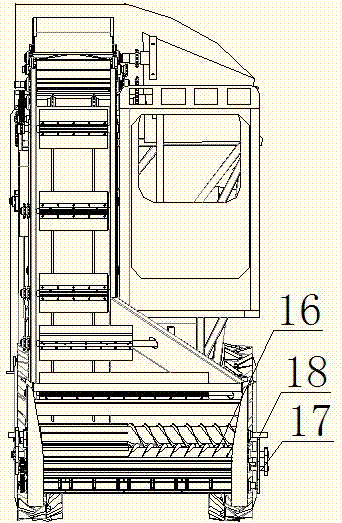

[0031] The drawings show a specific embodiment of the invention. This embodiment includes a frame 1. The frame 1 is installed on the front drive axle 2 and the rear steering axle 3. The front end of the frame 1 is equipped with a cab 4, and the side of the cab 4 is equipped with an elevator 5, and the front end of the elevator 5 The header 6 is connected, the rear end of the elevator 5 is connected with a pulverizer 7, the lower part of the connection between the elevator 5 and the pulverizer 7 is equipped with a secondary recovery device 8, and the lower part of the frame 1 is equipped with a stubble cultivator 9. A hopper box 10 is installed on the frame 1 above the steering bridge 3. The secondary recovery device 8 is composed of a silo 11 and a fan 12. The silo 11 and the fan 12 are provided with a transmission shaft 13, and a spiral cutting propeller 14 and a fan blade 15 are respectively provided on the transmission shaft 13. The inclination angle of the elevator 5 is 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com