Moth-eye film

A moth-eye film and flat film technology, applied in the field of moth-eye film, can solve problems such as generation of dirt, and achieve the effects of preventing condensation and excellent reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

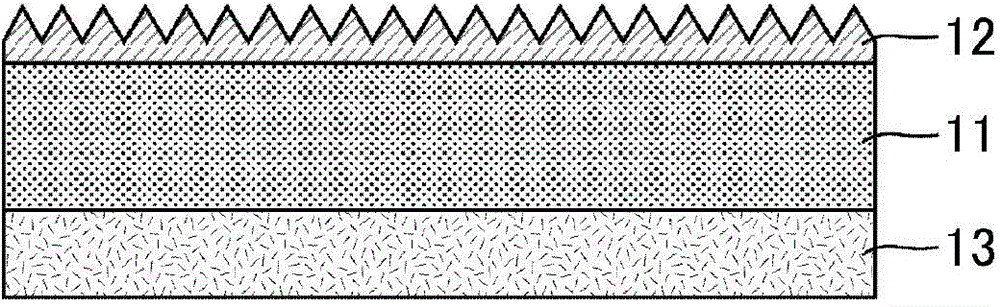

[0076] figure 1 is a schematic cross-sectional view of a laminate including the moth-eye film of Embodiment 1. like figure 1 As shown, the moth-eye film 12 of Embodiment 1 is attached to an article to be an antireflection object through the base film 11 and the adhesive layer 13 . The moth-eye film 12 includes concavo-convex portions and a base portion, and most of the light incident on the surface of the moth-eye film 12 is transmitted between the moth-eye film 12 and the article, so it is possible to obtain a film) far superior anti-reflection effect.

[0077] As an object to be anti-reflection, it can be suitably used for items placed in a low-temperature environment such as window glass of buildings, information displays, display windows, car windshields, rear windows, instrument panels, window glass, etc., but can also be used for Displays, water tanks, printed matter, photographs, painted items, lighting equipment, etc. for mobile phones, etc.

[0078] The material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com