A composite busbar suitable for igbt parallel connection

A composite busbar and parallel connection technology, applied in the direction of output power conversion devices, conductors, insulated cables, etc., can solve the problems of unbalanced current of parallel IGBT modules, damage to IGBT modules, uneven distribution of lead inductance, etc., to eliminate mutual inductance, High installation efficiency and uniform distribution of lead inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

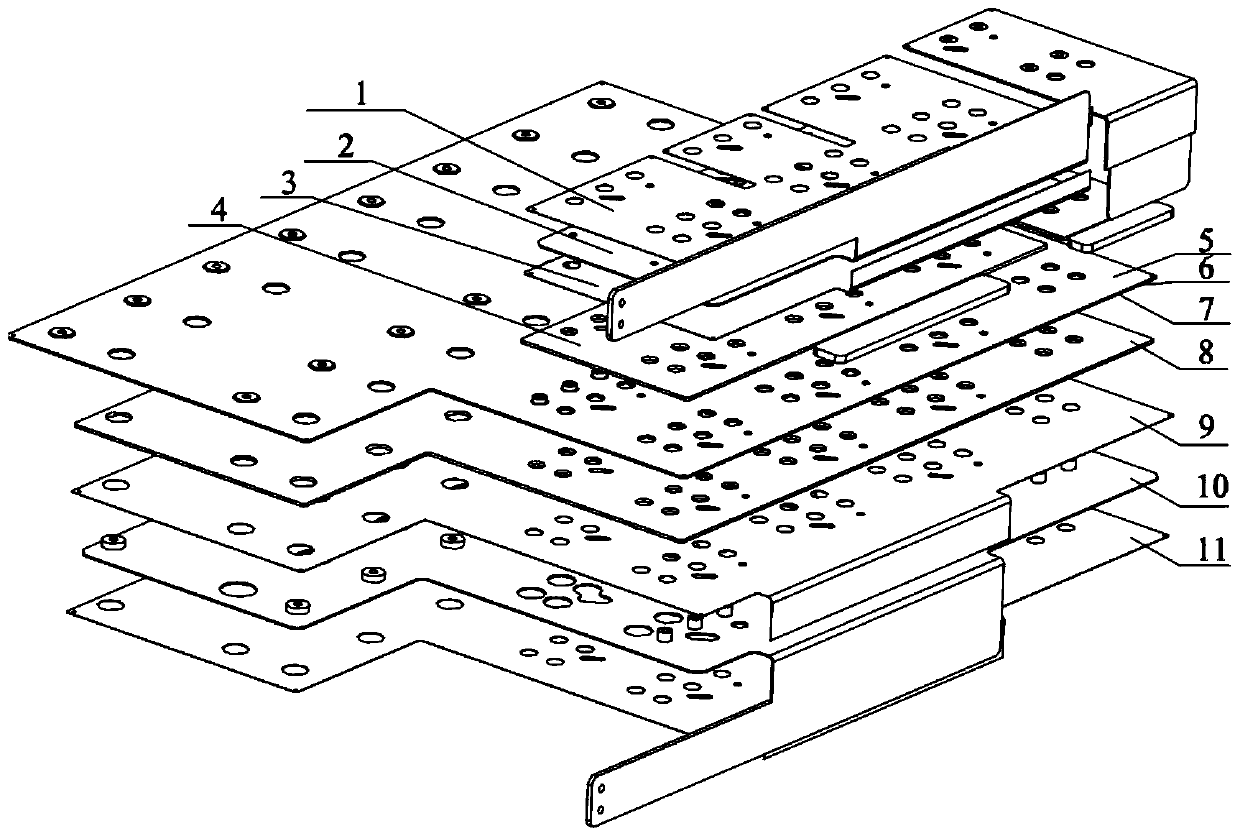

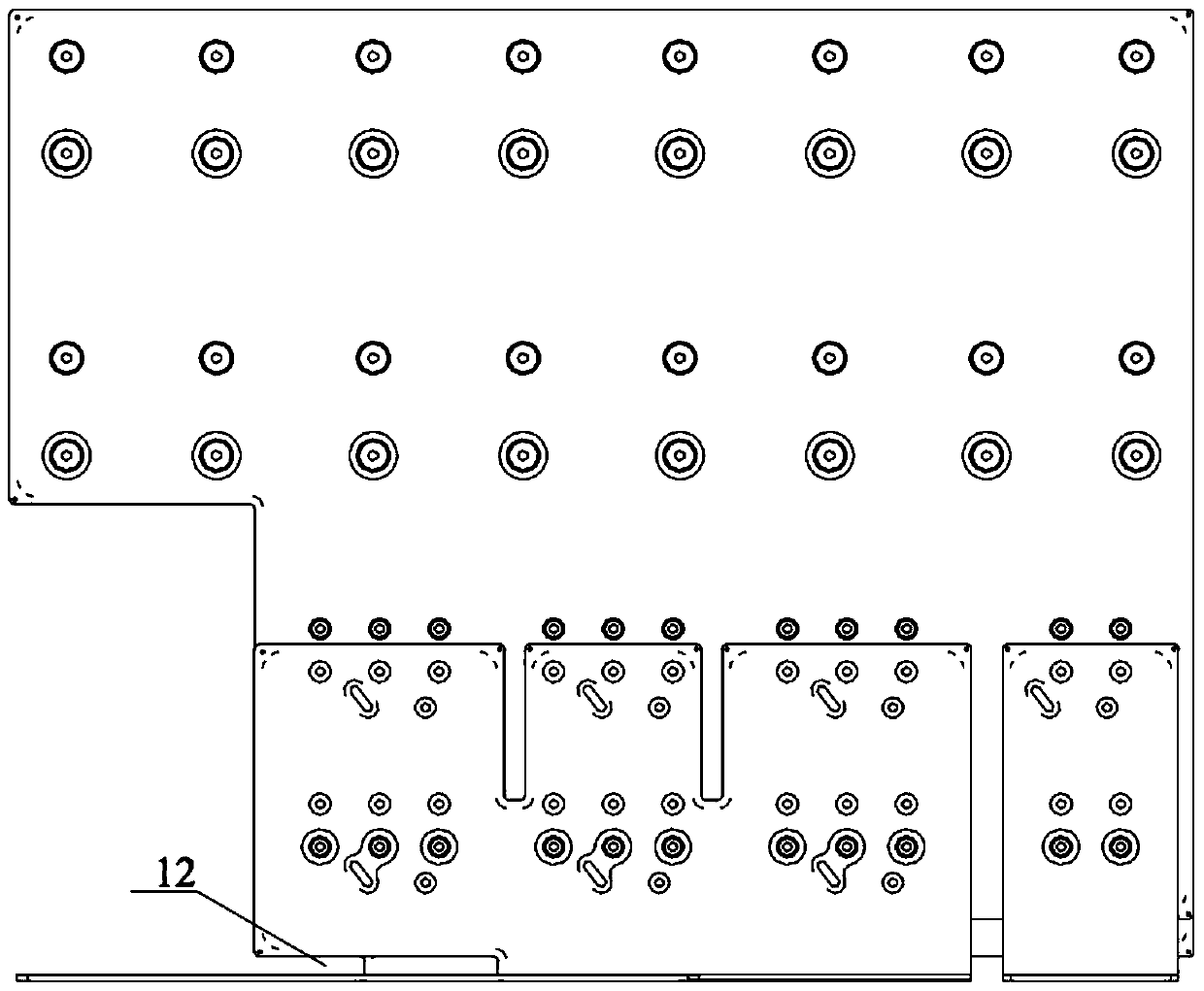

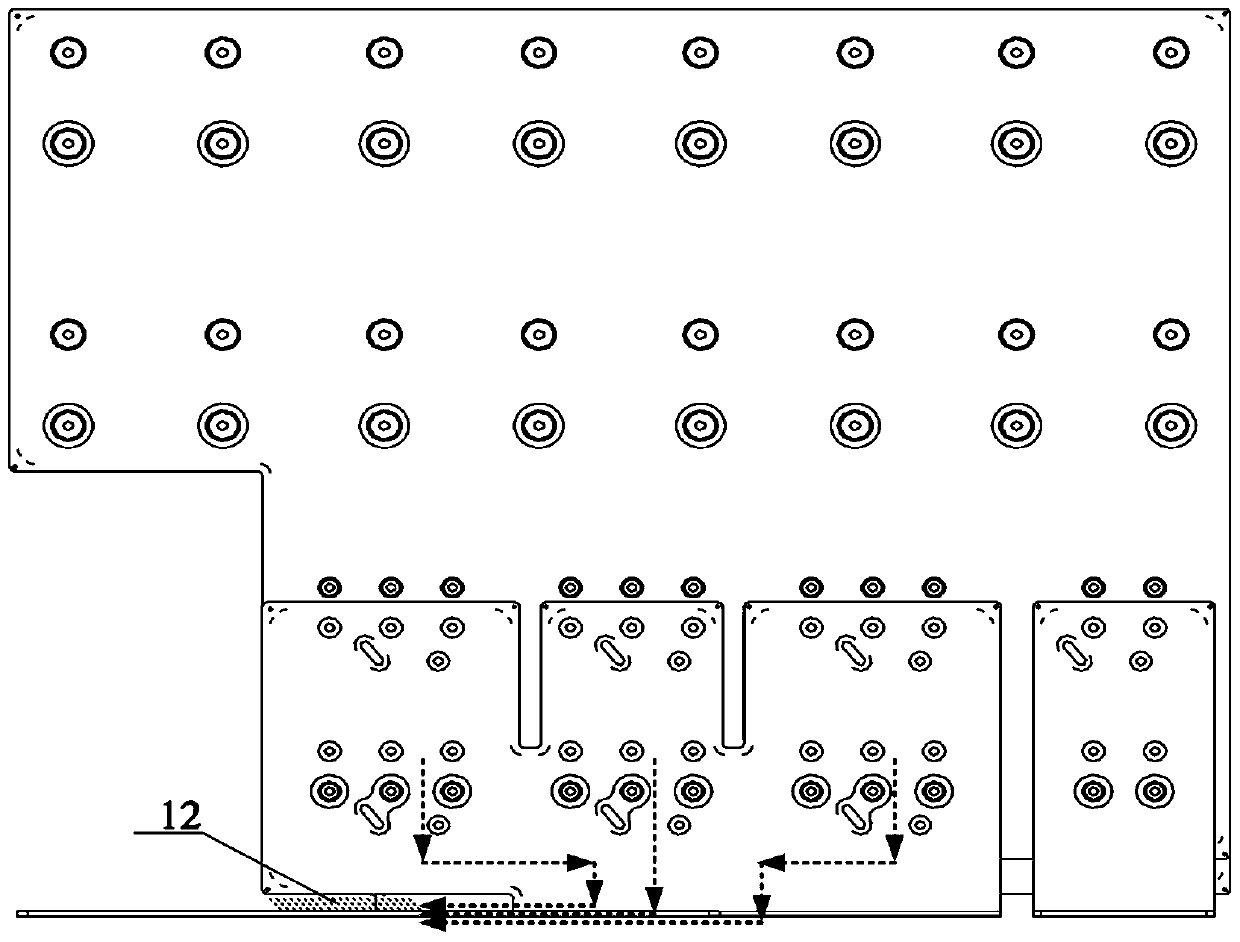

[0033] Such as Figure 1-4 As shown, the inventive composite busbar of this example is composed of multiple superimposed conductor layers, insulating layers, and insulating plates. The composite busbar includes an insulating layer 1 and an AC output plate conductor layer 2 arranged sequentially from top to bottom. , insulating layer two 3, insulating plate one 4, insulating layer three 5, positive plate conductor layer 6, insulating layer four 7, insulating plate two 8, insulating layer five 9, negative plate conductor layer 10 and insulating layer six 11. The composite busbar is according to insulating layer one 1, AC output plate conductor layer 2, insulating layer two 3, insulating plate one 4, insulating layer three 5, positive plate conductor layer 6, insulating layer four 7, insulating plate two 8, Insulating layer five 9, negative plate conductor layer 10 and insulating layer six 11 are sequentially stacked on the mold layer by layer; the composite busbars after stackin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com