Control circuit of power conversion circuit and relevant capacitor charging circuit

A power conversion circuit and control circuit technology, which is applied to control/regulation systems, output power conversion devices, electrical components, etc., can solve the problems of the power conversion circuit being unable to operate normally, consumption, and insufficient charge of the bootstrap capacitor. The effect of saving circuit area, simplifying architecture, reducing component complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below in conjunction with related drawings. In the drawings, the same reference numerals represent the same or similar elements or method flows.

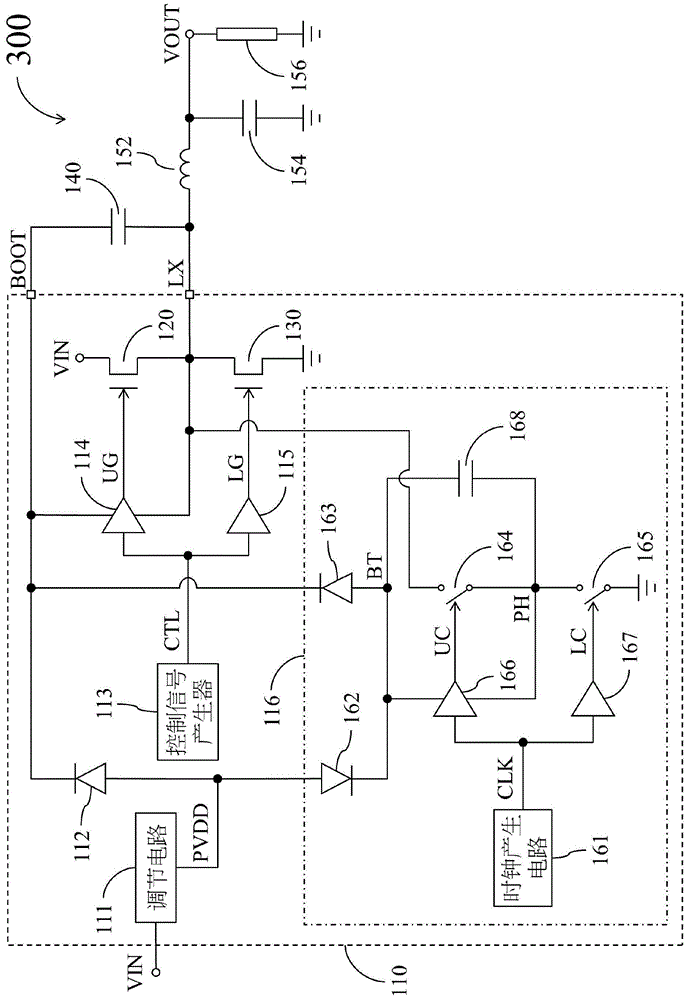

[0038] figure 1 It is a simplified functional block diagram of the power conversion circuit 100 according to an embodiment of the present invention. The power conversion circuit 100 includes a control circuit 110 , a high-side switch 120 , a low-side switch 130 , a bootstrap capacitor 140 , an inductor 152 , an output capacitor 154 , and a load 156 . The control circuit 110 is coupled to the upper bridge switch 120 and the lower bridge switch 130 and configured to control the operation of the upper bridge switch 120 and the lower bridge switch 130 . The high-bridge switch 120 is coupled between the input terminal of the power conversion circuit 100 and the first node LX. The low bridge switch 130 is coupled between the first node LX and a fixed potential terminal (suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com