Array fiber laser device, amplifier and manufacturing methods of multi-core fiber

An array fiber and laser technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The array fiber laser of the present invention uses a coreless fiber to introduce pumping light into a multi-core fiber, and performs multiple side pumps on the gain fiber in the multi-core fiber to realize multi-wavelength laser output.

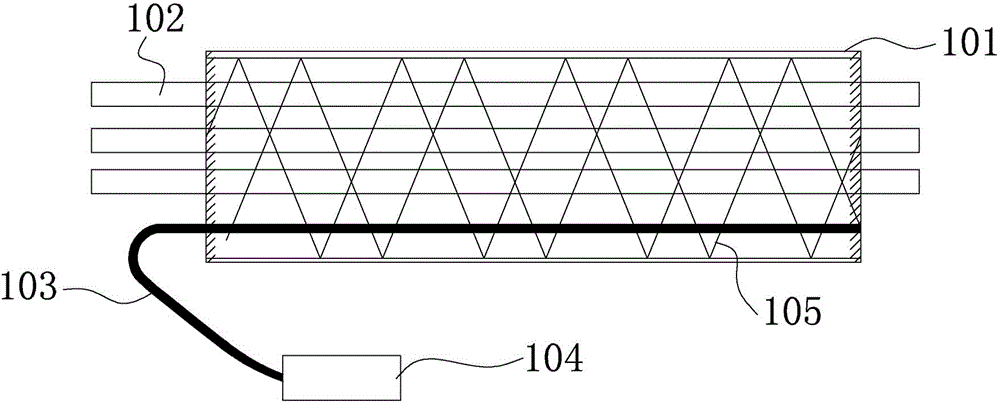

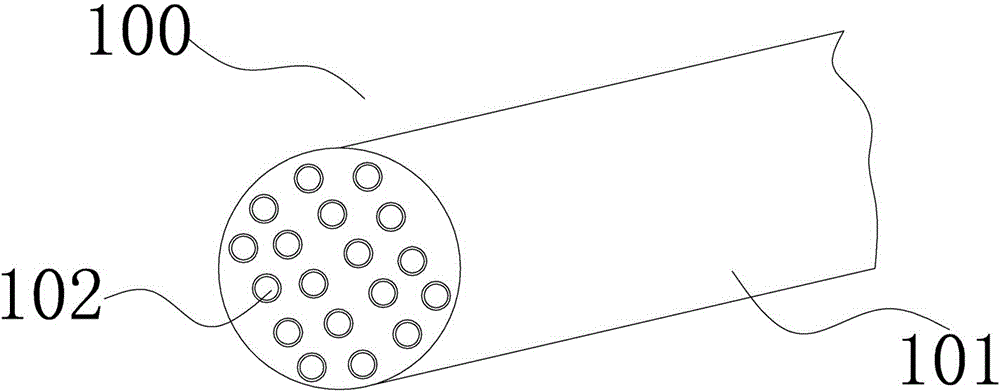

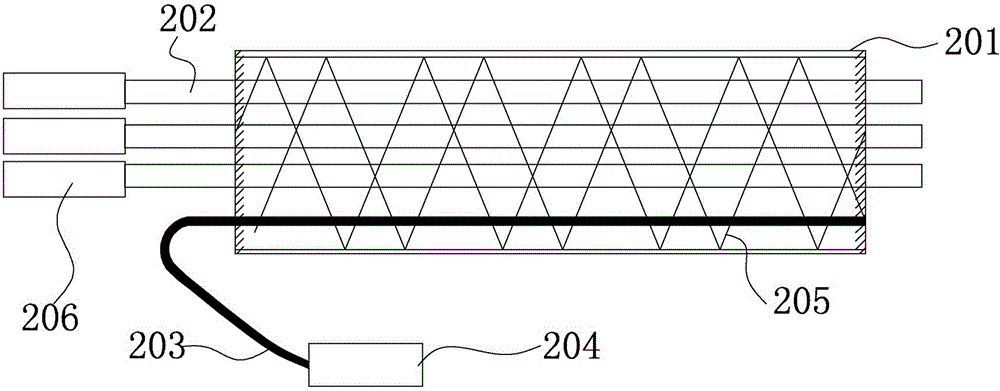

[0025] Specifically, such as figure 1 The illustrated embodiment of the array fiber laser includes a multi-core optical fiber 100; the multi-core optical fiber 100 is a capillary 101, and a plurality of gain fibers 102 and coreless optical fibers 103 laid radially along the capillary 101 are fixed inside; the capillary The two ends and sides of 101 are coated with a high reflection film for pump light 105, or its two ends are coated with a high reflection film for pump light 105, and the side is provided with cladding; the end faces of each gain fiber 102 are for pump light 105. Light 105 highly refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com