Transparent cover layers for solar cells and modules

A technology of solar cells and covering layers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as reducing the efficiency of solar energy installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

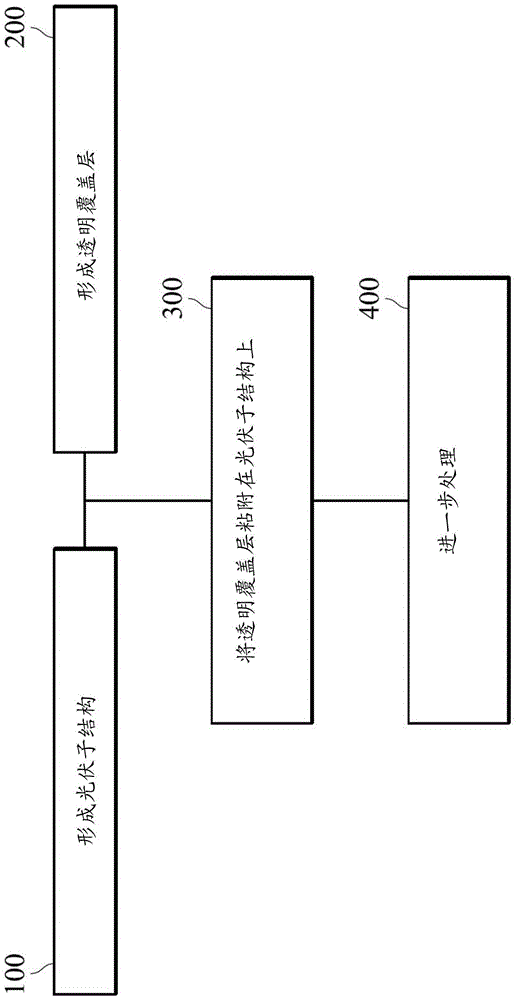

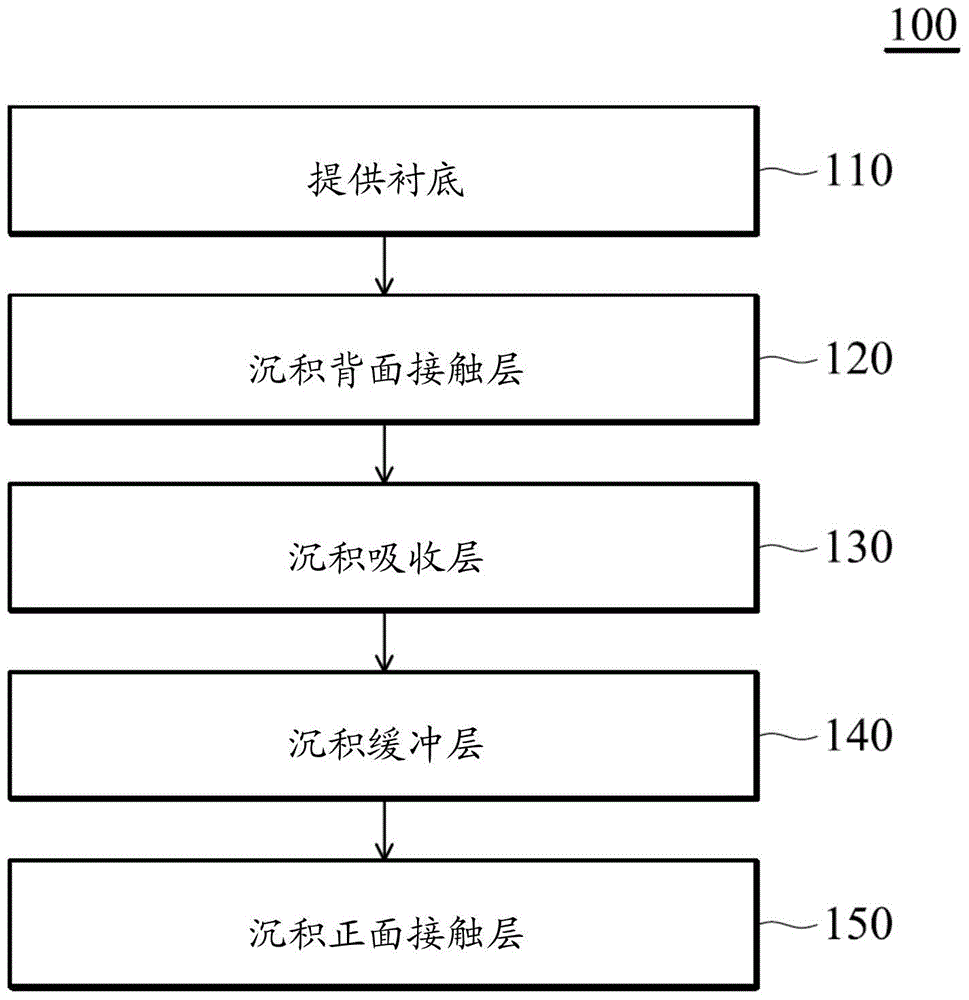

Method used

Image

Examples

example

[0073] A conventional protective covering (C00) consisting of glass is provided. For comparison, a transparent cover layer (C01) was produced according to the method described in the present invention. A thin film with Cu nanoparticles was deposited onto the front glass between the anti-reflective coating and the front glass. The thin film has a thickness of about 5 to 10 nm. The coating was annealed at 350 °C for 30 min. The transmittance of light through each cover layer C00 and C01 was measured.

[0074] Figure 15 Data are shown for the transmittance of light through C00 and C01 at various wavelengths. For wavelengths between about 450nm to 950nm, the C01 transparent cover layer has a higher transmission than the C00 glass. The highest observed transmission of the C01 transparent cover layer was about 95%, while the highest observed transmission of the C00 glass was about 92%.

[0075] In summary, the disclosed methods and transparent cover layers allow for increased...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com