Hot-rolled H profile steel mechanical property forecasting method based on multivariate linear regression analysis

A multiple linear regression and H-shaped steel technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low quality levels, achieve broad application prospects, avoid resource waste, and have obvious energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described in detail with the accompanying drawings and specific embodiments.

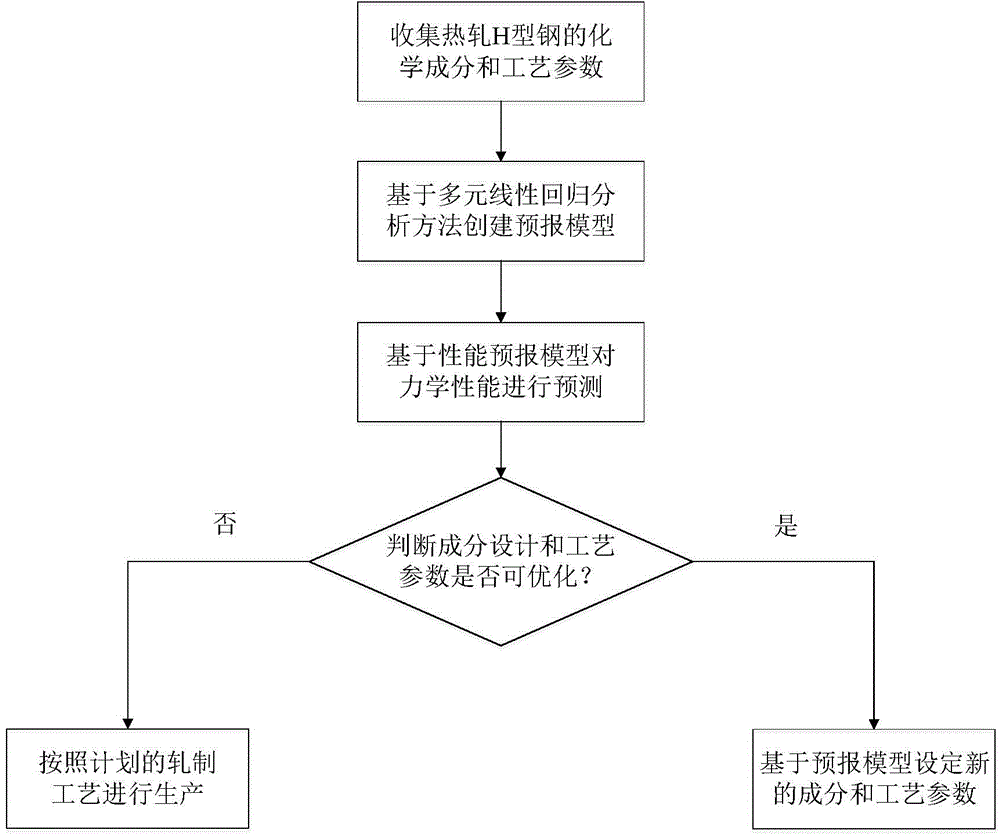

[0066] figure 1 In, the key steps of the technical solution of the present invention are given:

[0067] 1. Collect data on chemical composition and process parameters of hot-rolled H-beam;

[0068] 2. Using multiple linear regression analysis method to obtain the mechanical performance prediction model of hot-rolled H-beam

[0069] 3. Predict the performance of hot-rolled H-beam based on the mechanical performance prediction model;

[0070] 4. Determine whether the composition design and process parameters can be optimized?

[0071] 5. If not, proceed to production according to the original rolling process parameters, otherwise proceed to the next step;

[0072] 6. Based on the mechanical performance prediction model, adjust the chemical composition and process parameters of the hot-rolled H-beam;

[0073] 7. Set new production parameters for hot-ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com