High-power optical fiber cladding power stripper device

A fiber cladding and stripper technology, applied in the directions of light guides, optics, instruments, etc., can solve the problems of difficulty in making fiber tapers, difficult to remove low numerical aperture light, low power stripping efficiency, etc. The effect of stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

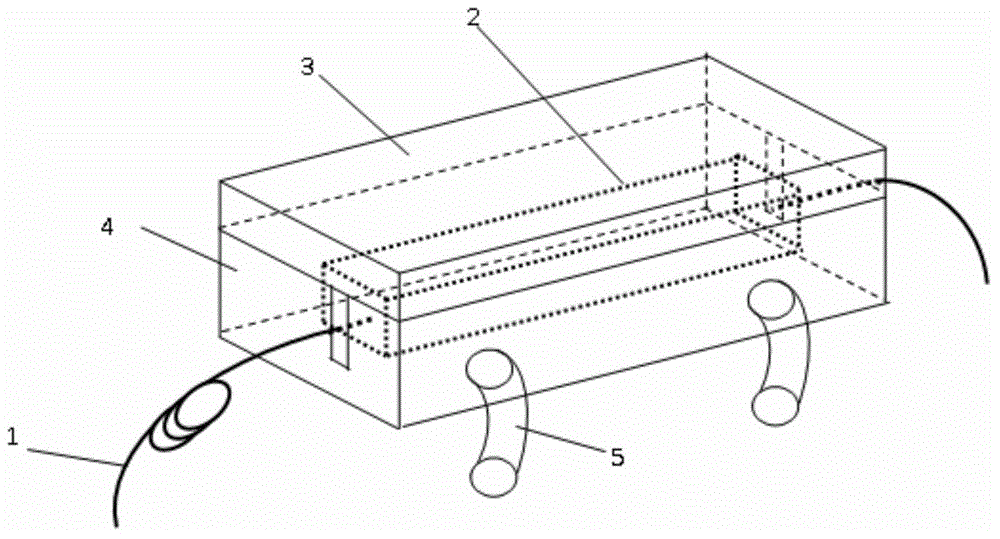

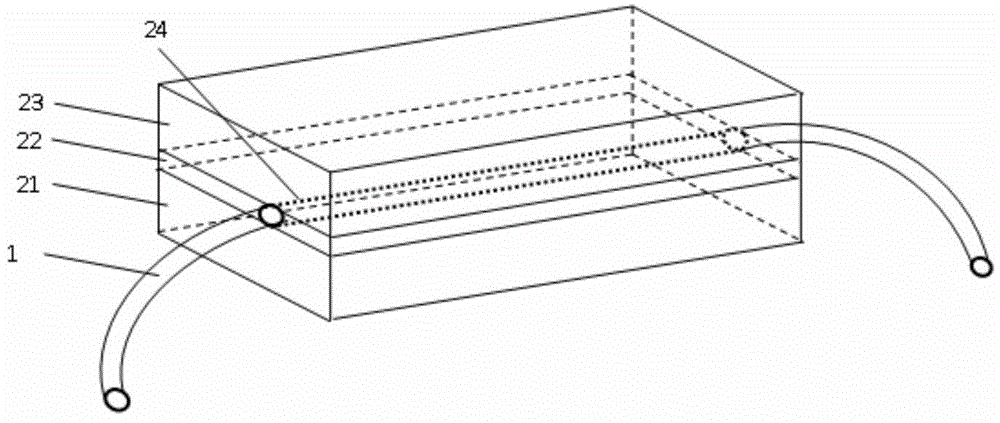

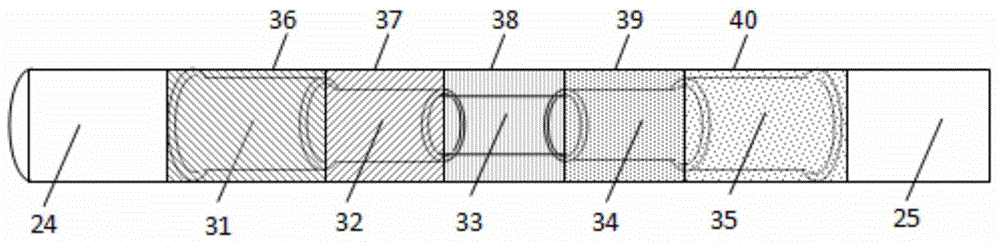

[0019] A high-power optical fiber cladding power stripper device such as figure 1 As shown, including the diameter r 0 Double-clad fiber 1, optical module 2, upper cover 3, water cooling base 4, water cooling tube 5, figure 1 Medium optical module 2 such as figure 2 As shown, the diameter including the inner cladding is r 0 Double-clad fiber 1, partially stripped inner cladding double-clad fiber 24, refractive index n L The light-transmitting material 21, the refractive index is n J The high refractive index optical gel 22, the refractive index is n K The light-transmitting material23. figure 2 Strip the inner cladding double-clad fiber 24 such as image 3 Shown.

[0020] In order to make the power stripper improve the stripping efficiency and make the inner cladding leakage light leak more evenly along the length of the optical fiber, such as image 3 The part of the double-clad inner cladding is stripped to form a stepped form 31, 32, 33, 34, 35, and coated with n 1 High refra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com