Bilateral dislocation differential confocal element parameter measuring method

A technology of component parameters and measurement methods, applied in the direction of testing optical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

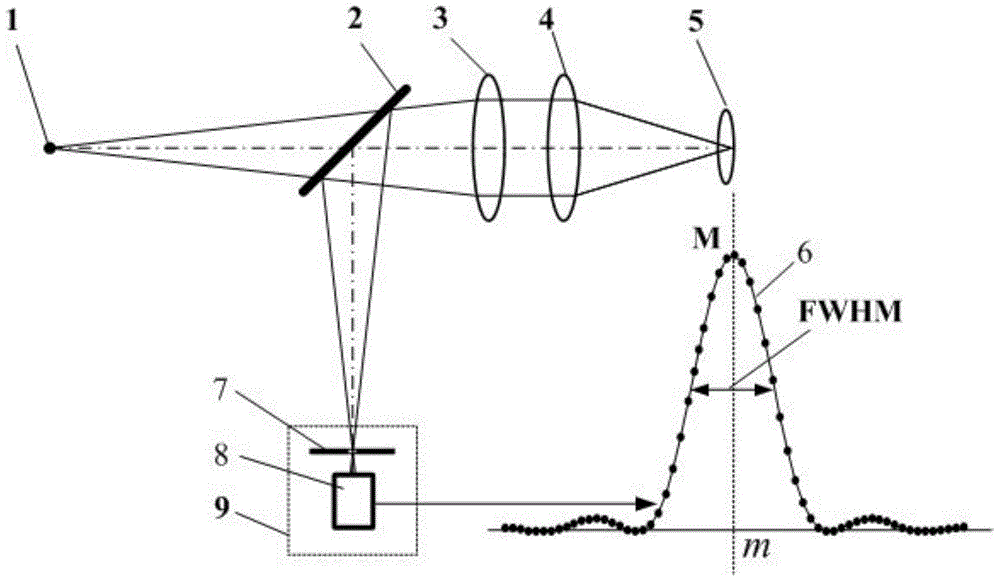

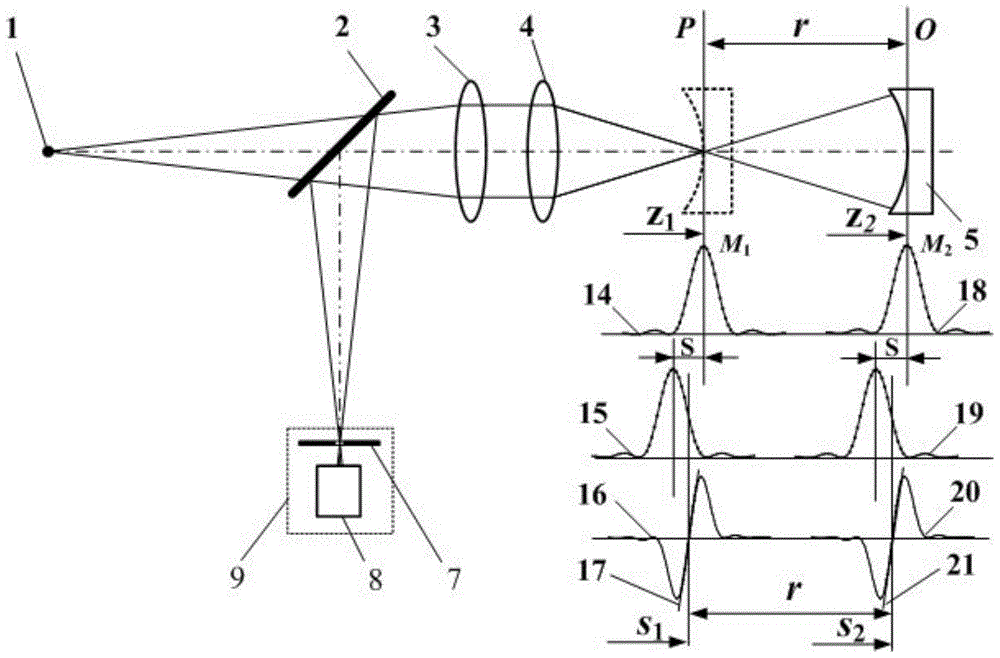

[0092] to combine figure 2 , the specific steps of using the method of the present invention to measure the radius of curvature of the surface of the spherical element are as follows:

[0093] Step 1. Place the test piece 5 behind the converging objective lens 4, adjust the test piece 5 so that its optical axis is on the same optical axis as the measurement beam, and part of the light is reflected when it hits the surface of the test piece 5;

[0094] Step 2: Move the measured object 5 to scan along the optical axis, and the confocal detection system 9 detects the corresponding vertex position Z 1 The spherical top confocal response data set 14;

[0095] Step 3: Continue to move the DUT 5 along the optical axis, and detect the corresponding sphere center position Z through the confocal detection system 9 again 2 The spherical center confocal response data set 18;

[0096] Step 4. Perform bilateral intersection and subtraction processing on the spherical top confocal respon...

Embodiment 2

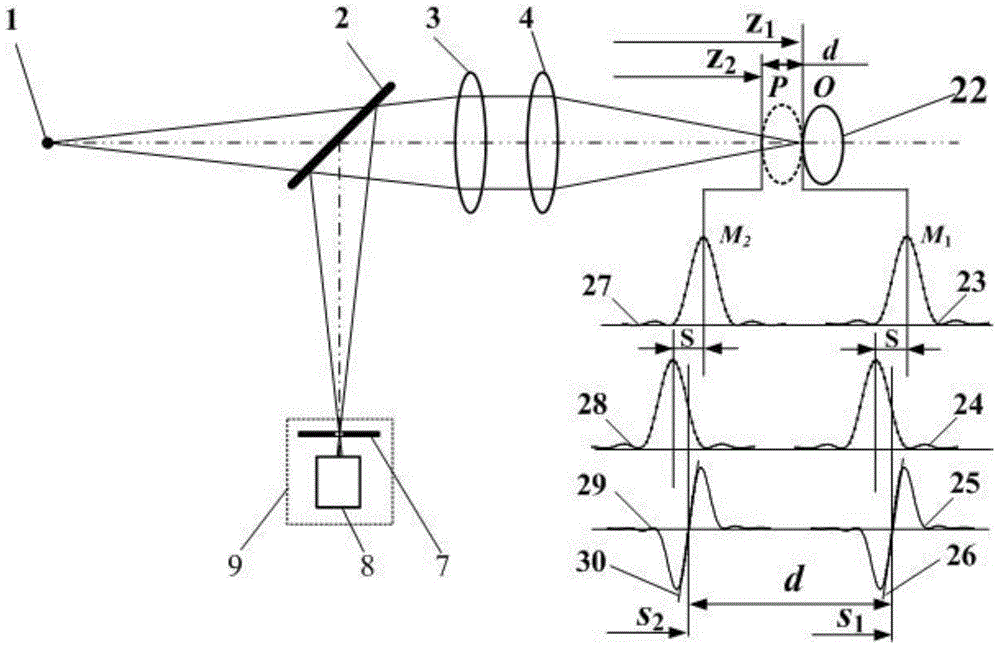

[0100] combine image 3 , utilize the method of the present invention to measure lens thickness concrete steps as follows:

[0101] Step 1, place the measured ball lens 22 behind the converging objective lens 4, adjust the measured ball lens 22 so that its optical axis and the measuring beam have the same optical axis, and the light beam converges near the left apex of the measured ball lens 22;

[0102] Step 2: Move the measured ball lens 22 to scan along the optical axis, and the confocal detection system 9 detects the position Z corresponding to the left apex 1 The left apex of the confocal response data set 23;

[0103] Step 3: Continue to translate the measured ball lens 22 along the optical axis, and detect the corresponding right apex position Z through the confocal detection system 9 again 2 The right vertex of the confocal response data set 27;

[0104] Step 4. Perform bilateral intersection and subtraction processing on the left apex confocal response data set 23 ...

Embodiment 3

[0109] The ball lens 22 to be tested is selected as a GCL-0101 K9 plano-convex lens, and its known parameters are: nominal refractive index n 1 = 1.51466, nominal thickness d = 4.000mm, radius of curvature r 1 =∞, r 2 =90.7908mm.

[0110] Measuring system, the maximum light aperture of the measuring mirror used is D=9.6mm, and the focal length is f 1 '=35mm, the aperture is R=4.5mm. The length measurement is carried out by using the nanoscale resolution grating to translate the length measurement guide rail device.

[0111] combine Figure 4 , the specific steps of measuring the refractive index of the lens by the method of the present invention are as follows:

[0112] Step 1: Place the measured ball lens 22 behind the converging objective lens 4, and adjust the converging objective lens 4 so that it has the same optical axis as the measuring beam. Place the plane reflector 31 behind the measured ball lens 22, adjust the plane reflector 31 so that it is perpendicular to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Focal length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com