Relative type rotary encoder and measurement method thereof

A rotary encoder and relative code technology, applied in the field of rotary encoders, can solve the problems that incremental encoders cannot immediately know the current position of the mechanism, affect the accuracy of measurement results, and encoder reading errors, etc., to achieve high reliability , Strong anti-pollution ability, and the effect of avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

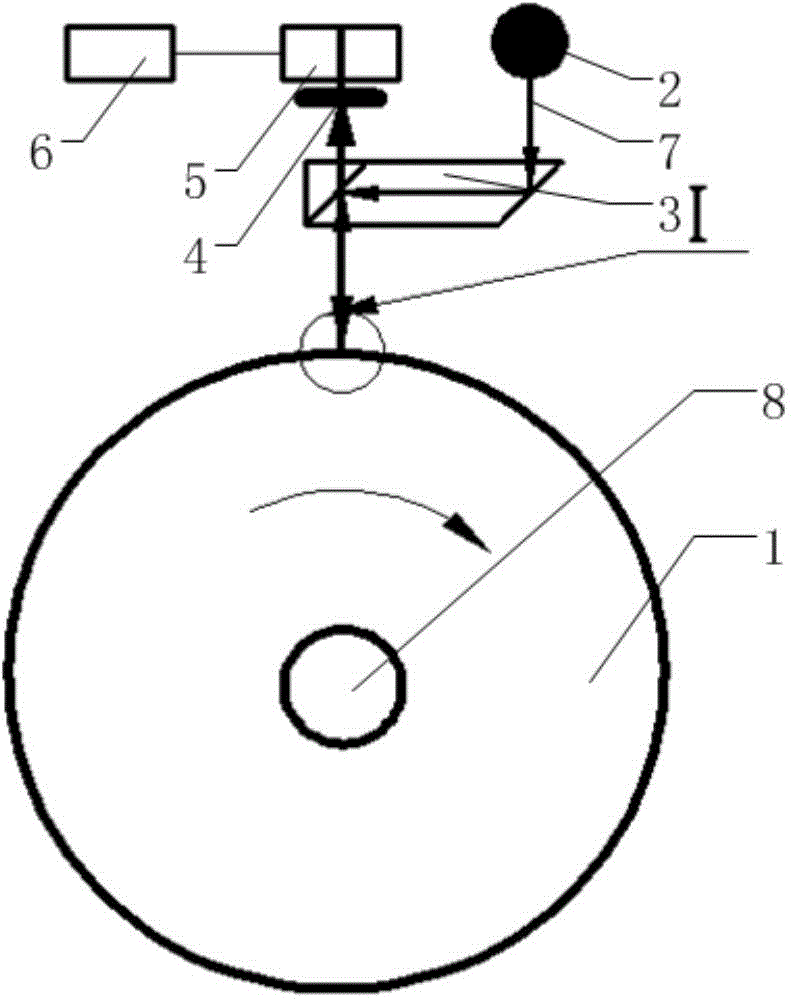

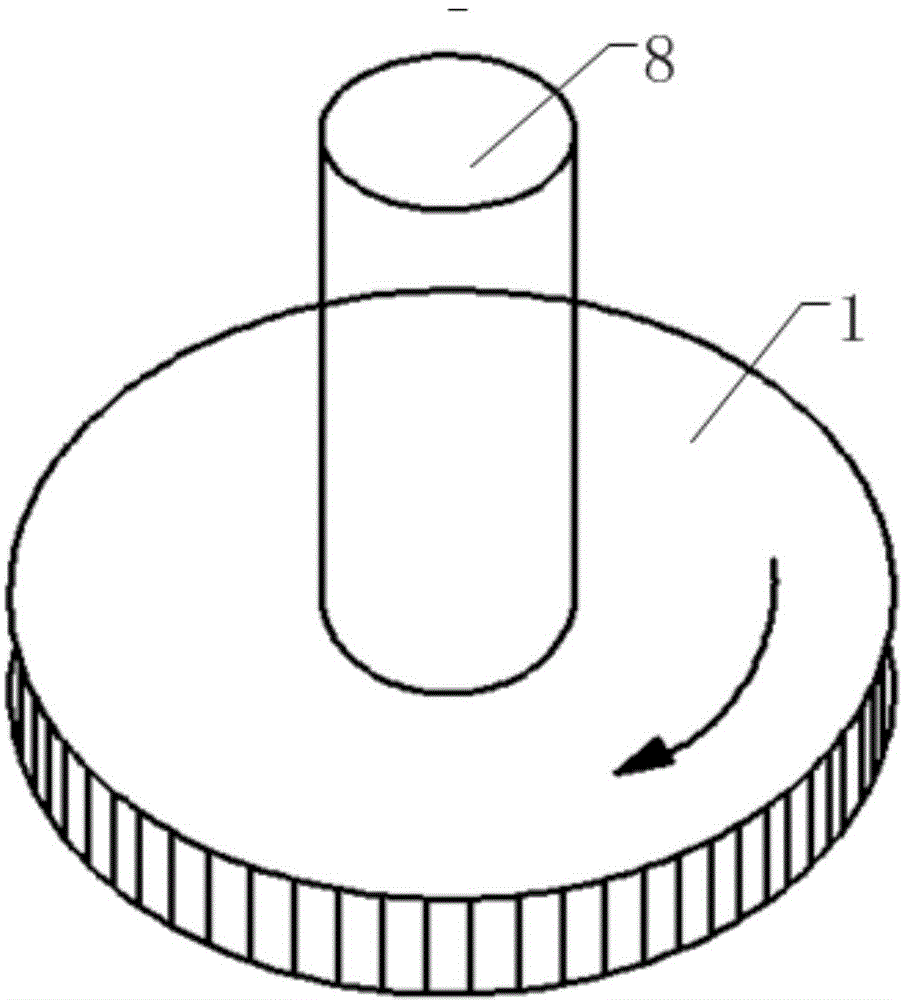

[0066] refer to Figure 1~Figure 4 , a relative rotary encoder for measuring the rotation angle of a servo motor, including a circular encoder disk 1, a rotating shaft 8, a data processing module 6, a housing, a plurality of light source systems and a plurality of photoelectric sensors 5, the rotating shaft 8 is connected with the servo motor through a shaft coupling, the circular encoder disk 1 is vertically installed on the rotating shaft 8, the housing is fixed on the frame of the servo motor and the rotating shaft 8 and the circular encoder disk 1 are both located on the machine in the frame;

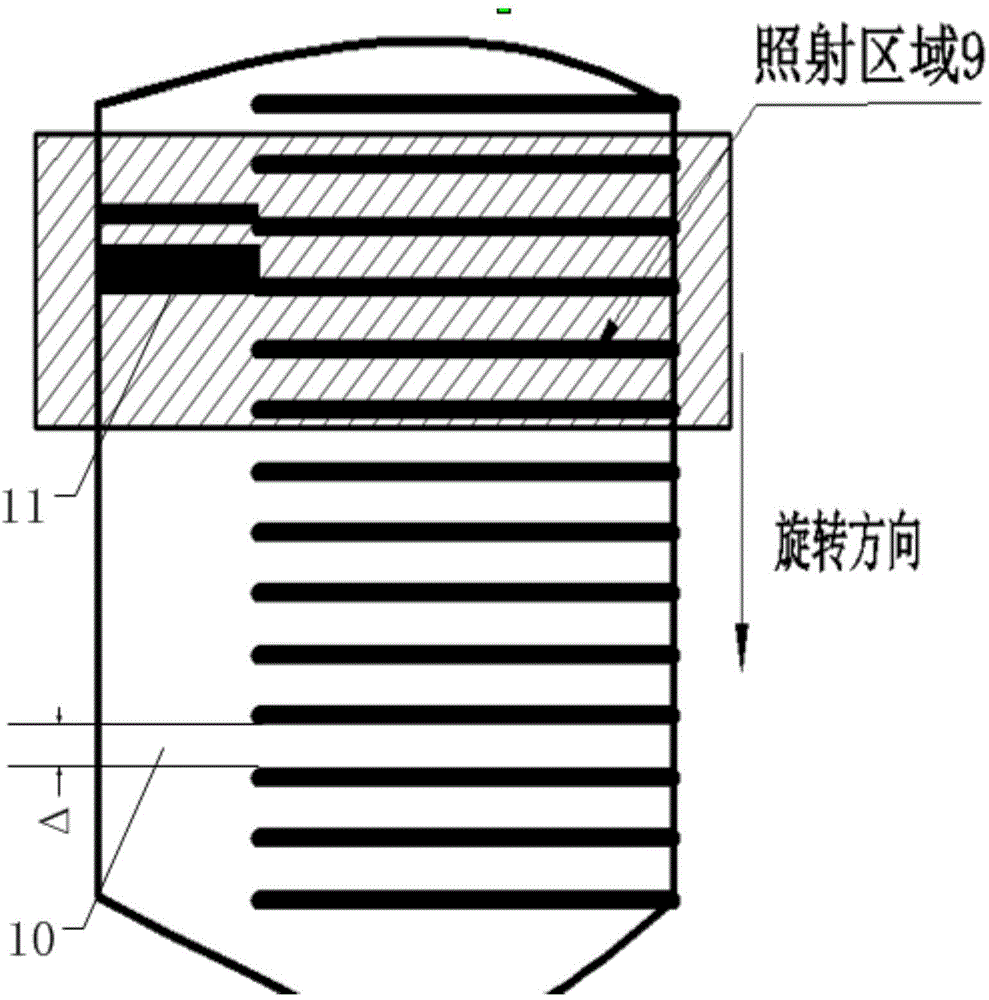

[0067] The outer surface of the circular code disc 1 is provided with a relative code track and a reference zero code track, the reference zero code track is arranged next to the relative code track, and the relative code track includes a plurality of the same width and evenly described The grating stripes on a circumference of the outer surface of the circular code disc 1, the ref...

Embodiment 2

[0082] A method for measuring a relative rotary encoder in Embodiment 1, comprising:

[0083] S1. Install a rotary encoder on the servo motor to be tested;

[0084] S2. The rotating shaft 8 of the rotary encoder rotates under the drive of the servo motor, so that the light emitted by the light source system scans and irradiates the relative code track and the reference zero code track on the outer surface of the circular encoder disc 1;

[0085] S3, the light is irradiated onto the photoelectric sensor 5 after being reflected by the grating stripes of the relative code track and the reference zero code track respectively;

[0086] S4, the photoelectric sensor 5 collects the image of the grating stripe reflected by the relative code track and outputs the corresponding time sequence pulse signal after light and dark sensing, and simultaneously collects the image of the grating stripe reflected by the reference zero code track and outputs the corresponding zero-crossing point aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com