Solar thermal collector and method of using same for converting solar energy into moderate temperature heat

A technology of solar heat collectors and heat collecting tubes, which is applied in the directions of solar heat collectors, solar thermal energy, and solar heat collectors using working fluids, etc., which can solve the problems of high cost of heat collection mode, small focus ratio of non-tracking focus mode, and inability to Combining with factory buildings and other issues to achieve excellent light transmission, improve system reliability, and reduce system costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

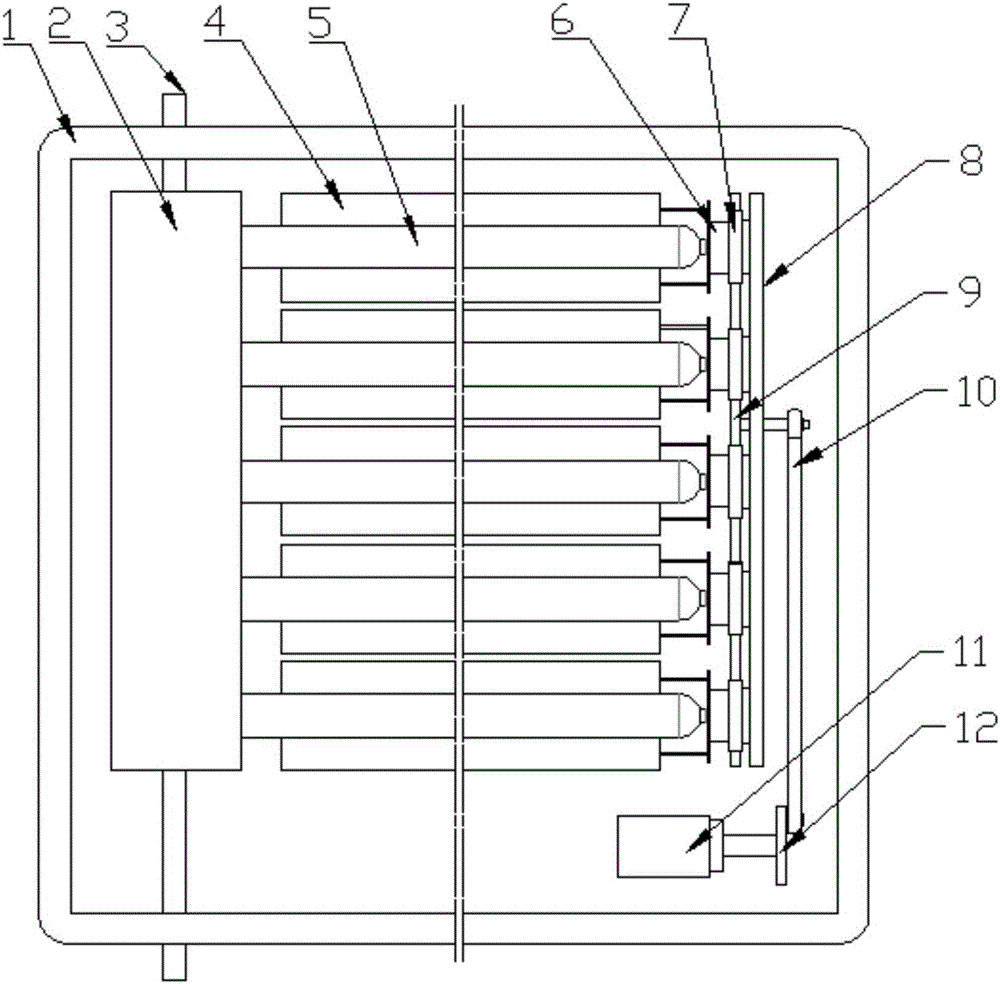

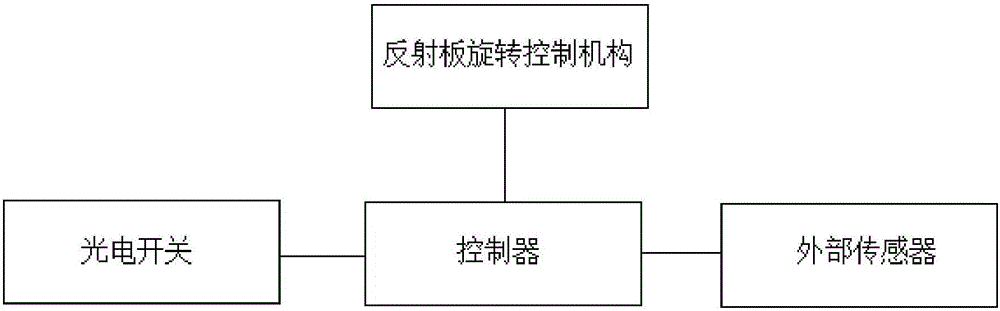

[0029] see figure 1 , the solar heat collector includes a heat collecting tube, and also includes a reflector and a reflector rotation control mechanism; the reflector is located at the back of the heat collecting tube and the focal axis of the reflector coincides with the axis of the heat collecting tube; the reflector is used to Solar energy is concentrated on the heat absorber of the heat collecting tube through reflection to form thermal energy; the reflector rotation control mechanism is used to drive the reflector to rotate around the focal axis, so that the reflector rotates following the change of sunlight. A reflecting plate is arranged on the back of each heat collecting tube. The reflector rotation control device includes a controller, an external sensor, a photoelectric switch and a reflector rotation control mechanism; the photoelectric switch is used to determine the initial position of the reflector; the external sensor is used to detect real time and local time...

Embodiment 2

[0032] In Embodiment 2, the reflector rotation control mechanism includes a connecting rod, a transmission gear, a bracket, a rack, a transmission rod, a motor, and a motor turntable; one end of the connecting rod is fixedly connected to the reflector, and the other end is fixed to the transmission gear. connection; the axis of the connecting rod and the axis of the transmission gear coincide with the axis of the heat collecting tube; the transmission gear is rotatably mounted on the bracket; the motor turntable is fixedly mounted on the drive shaft of the motor, and one end of the transmission rod is connected to the The other end is connected to the rack; the rack is located below the transmission gear and meshed with the transmission gear; the motor drives the transmission rod to reciprocate along the axis of the transmission rod through the motor turntable, so that the transmission rod drives the rack Reciprocate back and forth along the length of the rack, the rack drives ...

Embodiment 3

[0034] In Embodiment 2, the reflector rotation control mechanism includes a connecting rod, a transmission gear, a bracket, a rack, a motor, and a motor gear; one end of the connecting rod is fixedly connected to the reflector, and the other end is fixedly connected to the transmission gear; The axis of the rod and the axis of the transmission gear coincide with the axis of the heat collecting tube; the transmission gear is rotatably mounted on the bracket; the motor gear is fixedly mounted on the transmission shaft of the motor, and the motor gear meshes with the rack; The rack is located below the transmission gear and meshes with the transmission gear; the motor drives the rack to reciprocate along the length direction of the rack through the motor gear, the rack drives the transmission gear to rotate, and the transmission gear drives the reflector to rotate; the The photoelectric switch is installed on the transmission gear, and the controller detects the initial position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com