Plastic composite pipe

A composite pipe and plastic technology, applied in the direction of hoses, pipes, rigid pipes, etc., can solve the problems of inconvenient operation and high production cost, and achieve the effects of reducing production costs, preventing pipe bursting, and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in detail below in conjunction with specific embodiments.

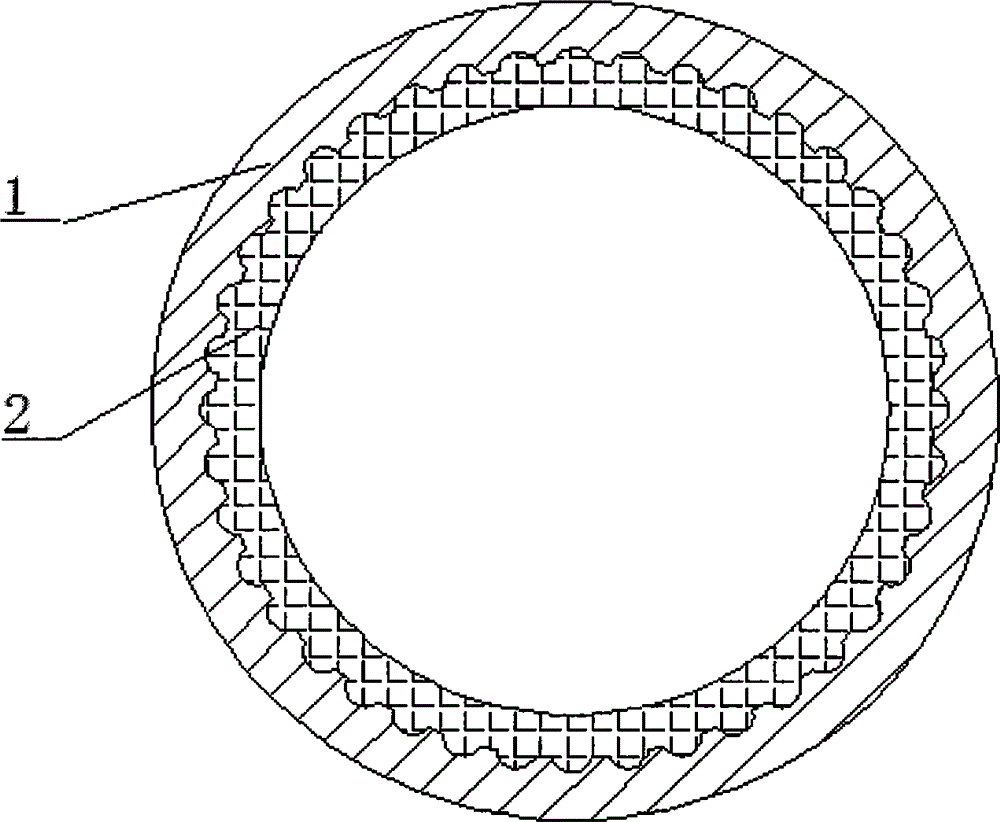

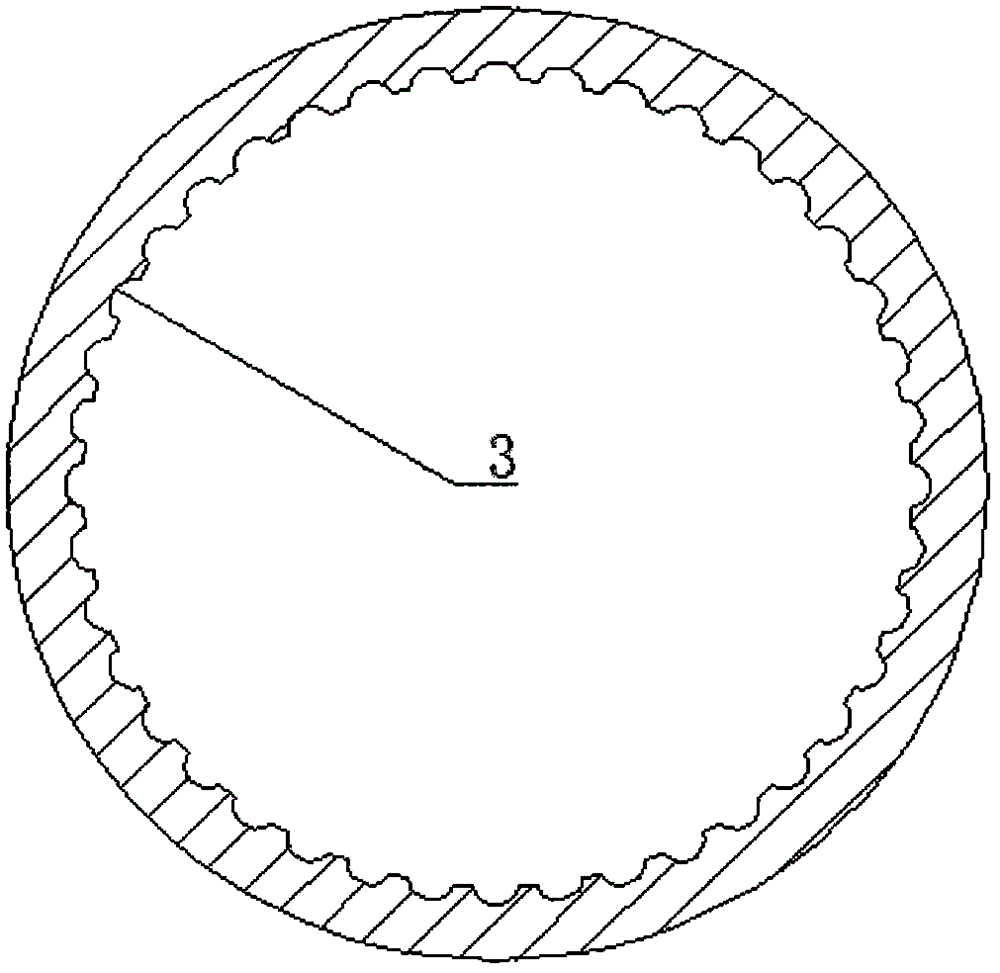

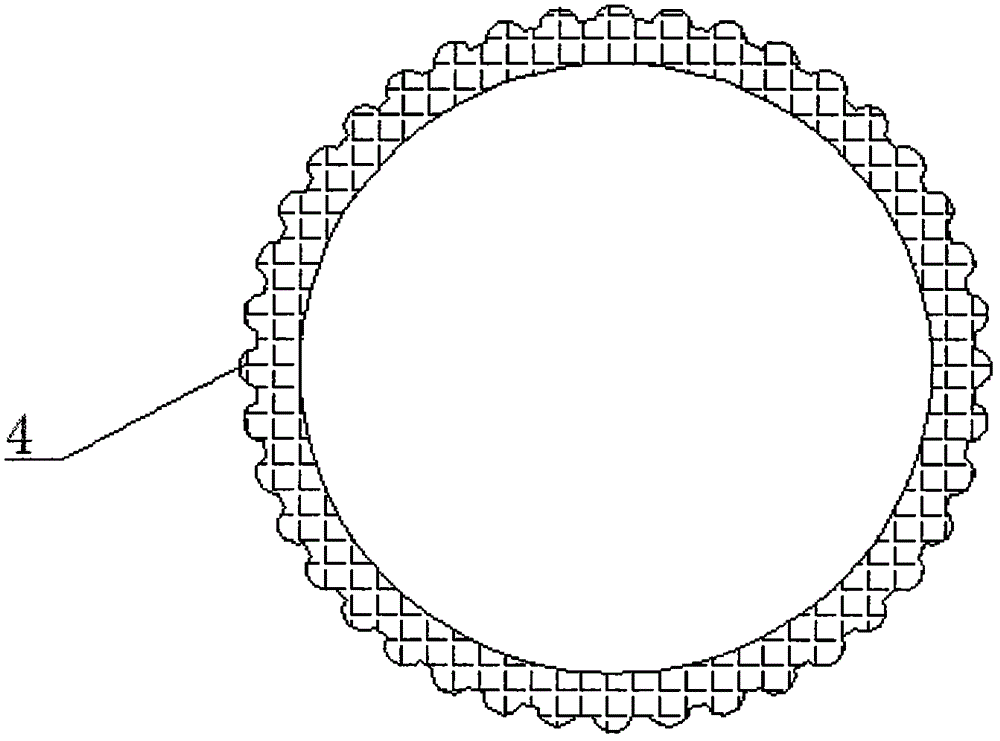

[0015] A plastic composite pipe, comprising an outer pipe 1 and an inner pipe 2, the inner side of the outer pipe 1 has an arc groove 3, the outer side of the inner pipe 2 has an arc protrusion 4, and the arc protrusion 4 is in the arc recess In the groove 3, the thickness ratio of the outer tube 1 to the inner tube 2 is 1:1, the arc radius of the arc raised part 4 is 1 / 4 of the thickness of the inner tube 2, and the outer tube 1 is made of polyvinyl chloride material. As, the inner tube 2 is made of polypropylene material.

[0016] The present invention combines the outer tube 1 and the inner tube 2 perfectly through the design of the arc groove 3 on the outer tube 1 and the arc protrusion 4 on the inner tube 2, and the outer tube 1 is thicker than the inner tube 2, which can ensure The pressure resistance of the pipe, the inner pipe 2 is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com