Flat gate valve

A flat gate valve and pressure relief technology, which is applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of valve plate distortion and increased working strength, and achieve the effects of reducing extrusion, easy switching operations, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

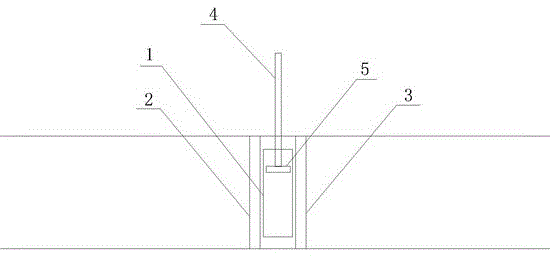

[0014] Example 1 as figure 1 As shown, the implementation of a pressure-relief flat gate valve includes a valve seat, a gate 1 and a valve stem 4. The valve seat is divided into a first valve seat 2 and a second valve seat 3, and the gate 1 and the second valve seat The first valve seat 2 and the second valve seat 3 are tightly fitted through a sealing ring. One end of the valve stem 4 is connected to the gate plate 1, and the other end is connected to a twist switch. The rotation of the knob switch drives the valve stem 4 to rotate, thereby driving the valve plate 1 to rise or fall.

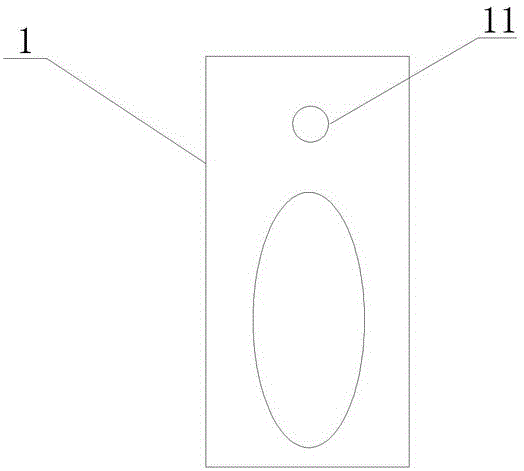

[0015] Such as figure 2 As shown, the gate 1 is provided with a cavity and a through hole 11, and a pressure relief component 5 is provided in the cavity, and the pressure relief component 5 is connected with the valve stem 4 through a screw rod. There is one through hole 11 , which is opened on any side of the valve plate 1 . The side of the through hole 11 close to the first valve seat 2 a...

Embodiment 2

[0016] Embodiment 2 The difference between this embodiment and Embodiment 1 is that there are two through holes 11 on the valve plate 1, which are distributed on both sides of the valve plate 1 respectively. The holes 11 protrude and retract in two directions, so as to achieve the purpose of pressure relief.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com