Electric controlled assembly of combination pump

A combined pump and electronic control technology, used in engine components, machines/engines, charging systems, etc., can solve the problem of not being able to control the injection rate and injection pressure, not directly changing the fuel volume and timing, and the large volume of the solenoid valve assembly. and other problems, to achieve the effect of simplifying the oil pump structure and intermediate links, fast conduction, and convenient transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

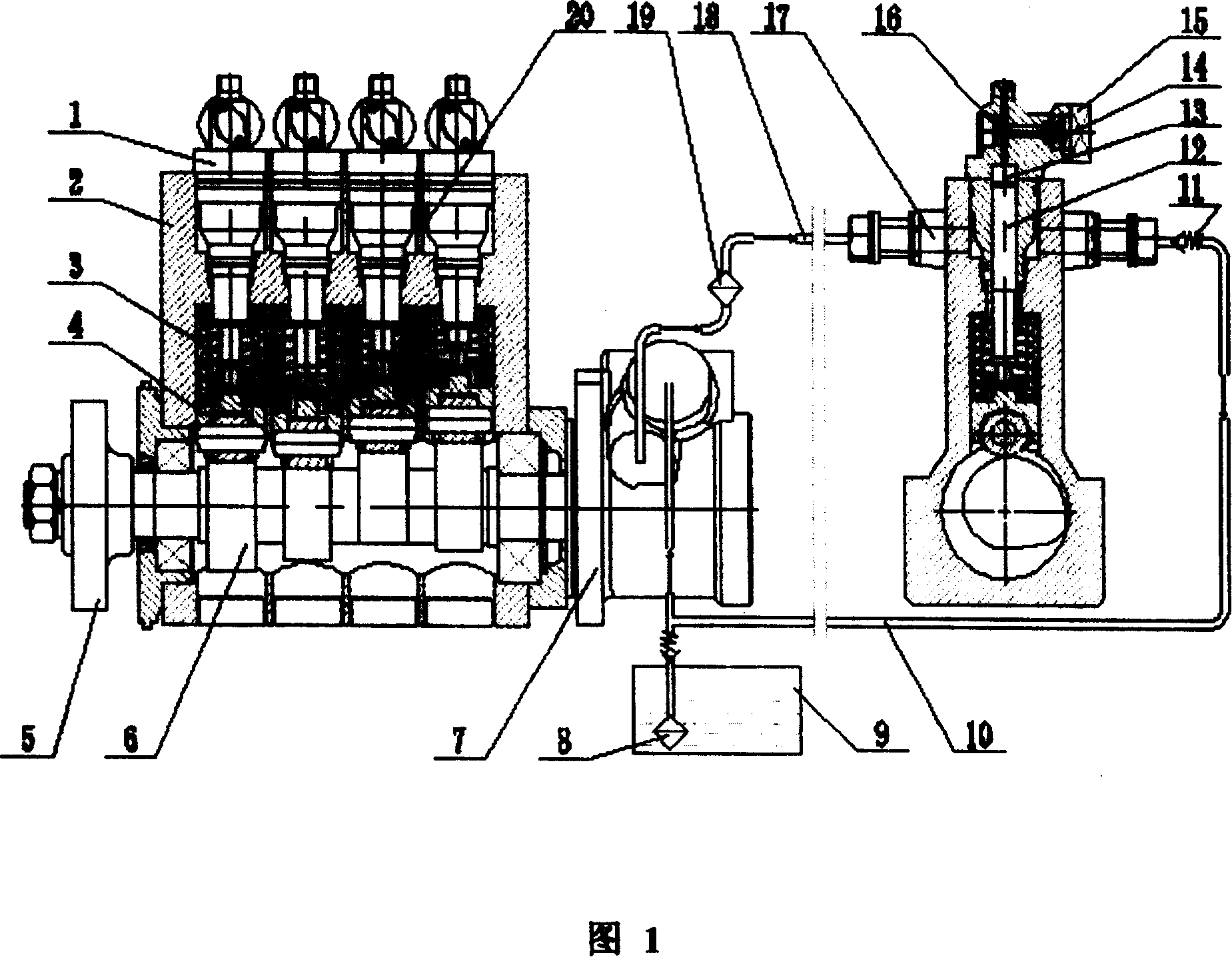

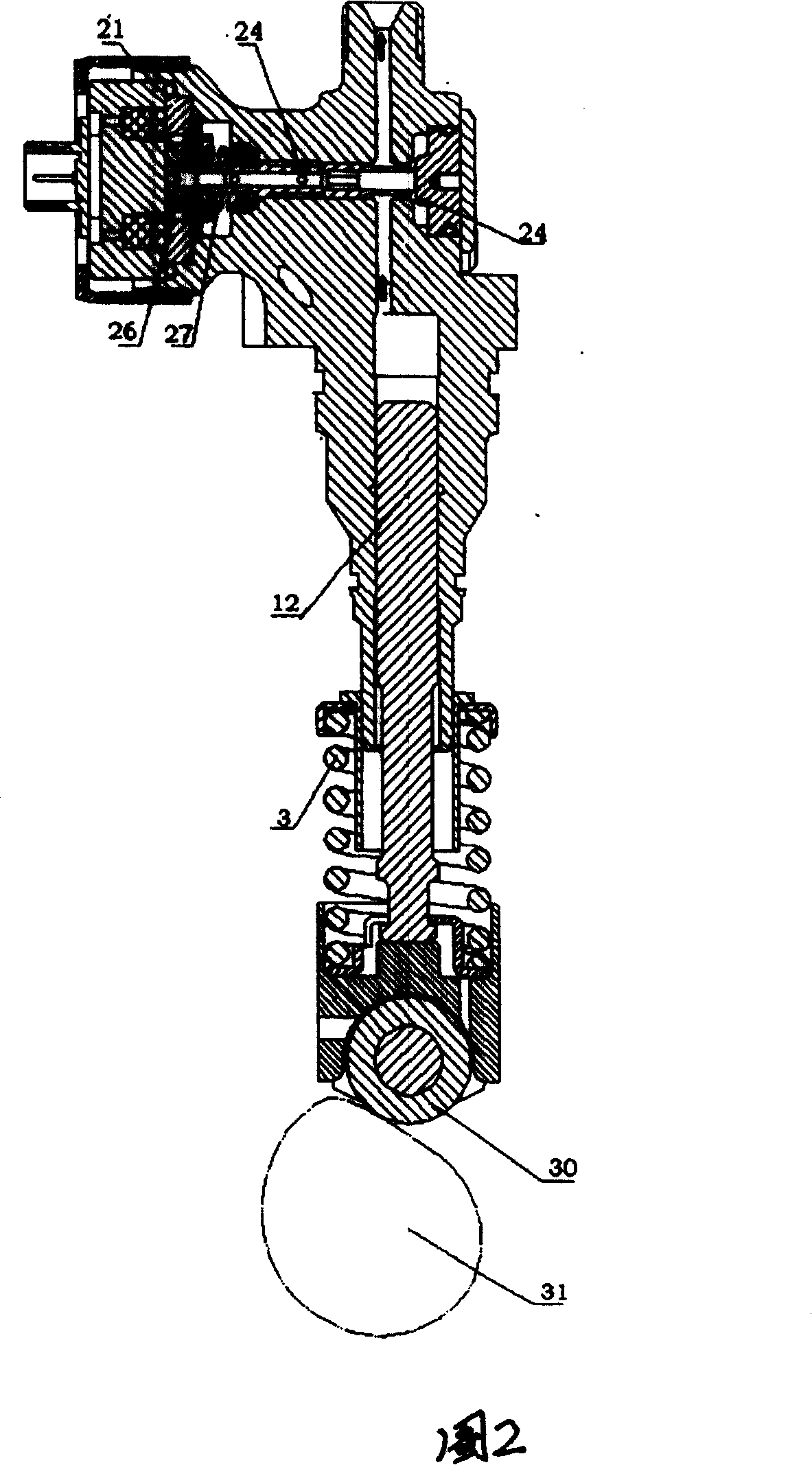

[0012] Fig. 1 is a schematic diagram of the structure of the electric control combined pump assembly, which is that the number of pump bodies 1 can be 4, 6 or 8, and only 4 pump bodies are shown in this accompanying drawing. The pump chamber used may be the pump chamber of a P-type pump.

[0013] In the schematic diagram of Fig. 1, the pump body 1, pump chamber 2, spring 3, roller and tappet assembly 4, coupling plate 5, camshaft 6, fuel delivery pump 7 and other auxiliary pumps of the electric control combination pump with in-line discharge are mainly described. An embodiment of an electronically controlled combination pump assembly composed of parts. Wherein the pump body 1 is mainly used for installing the plunger 12, the valve stem assembly 16 and the solenoid valve 15, etc., and a plunger hole and a valve stem hole are formed on the top of the pump body. In the middle of the pump chamber, there are interconnected inlet and outlet oil passages 17, 20. The camshaft 6 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com