Air returning type fan filter unit (FFU) below ceiling

A fan filter unit, air-type technology, applied in pump components, mechanical equipment, non-variable-capacity pumps, etc., can solve the problems of increased aerodynamic noise, large flow channel resistance, and the flow channel is not optimized, so as to prolong the replacement cycle. , Reasonable airflow organization and the effect of increasing dust holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

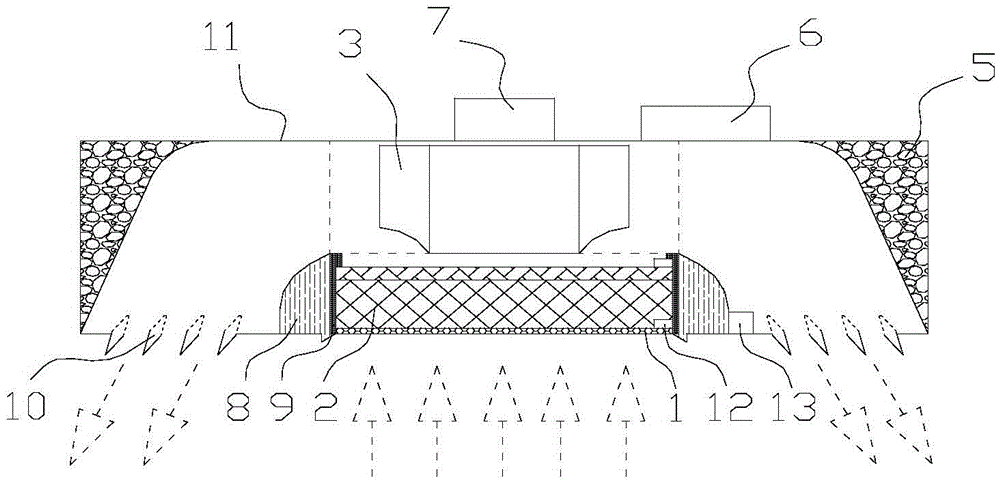

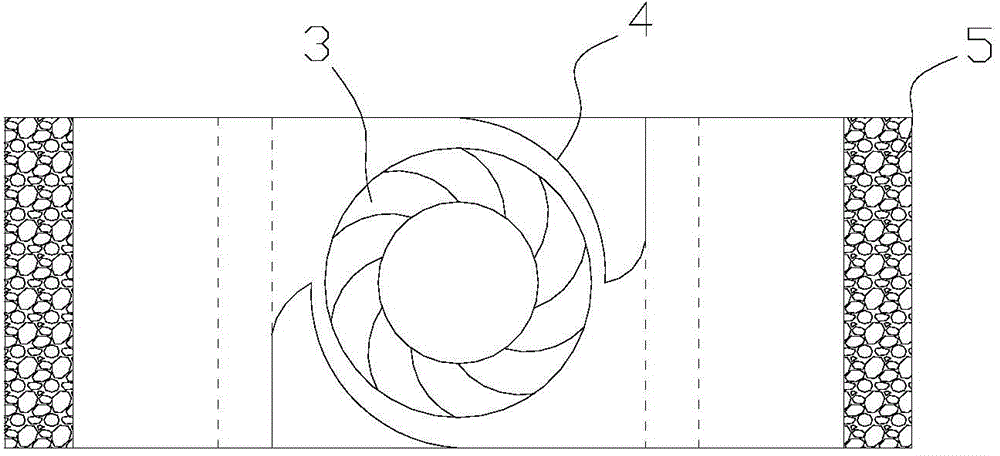

[0018] As shown in the accompanying drawings, a return air fan filter unit under the suspended ceiling of the present invention includes a box body 11 and a controller 6, and a return air port is opened in the middle of the bottom surface of the box body, and on both sides of the return air port Air outlets 10 are respectively arranged on the bottom surface of the box body, and a filter material unit is installed through a connection structure at the air return port. As a preferred embodiment of the present invention, the filter material unit is composed of return air outlet net 1, The multi-layer composite filter material 2 arranged on the return air outlet net 1 and the filter material support 9 sleeved on the outside of the return air outlet net 1 and the multi-layer composite filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com